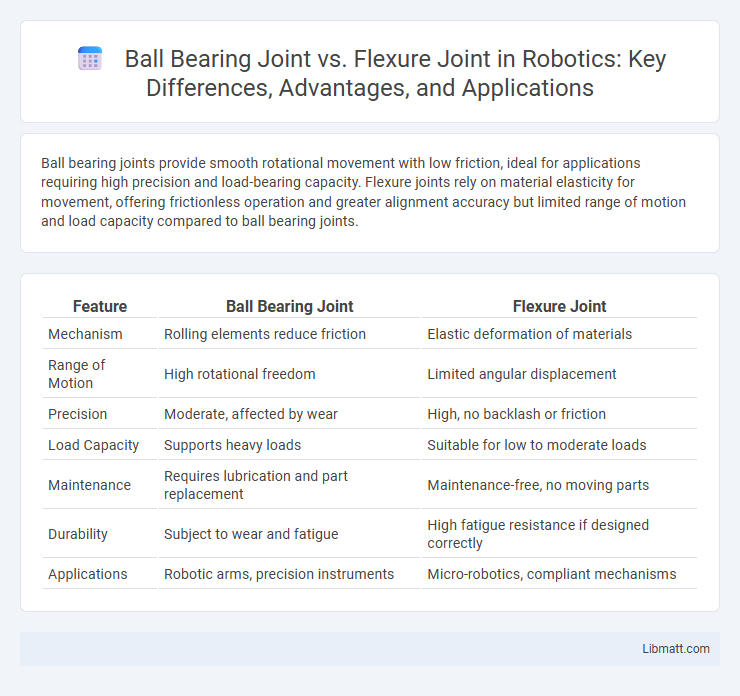

Ball bearing joints provide smooth rotational movement with low friction, ideal for applications requiring high precision and load-bearing capacity. Flexure joints rely on material elasticity for movement, offering frictionless operation and greater alignment accuracy but limited range of motion and load capacity compared to ball bearing joints.

Table of Comparison

| Feature | Ball Bearing Joint | Flexure Joint |

|---|---|---|

| Mechanism | Rolling elements reduce friction | Elastic deformation of materials |

| Range of Motion | High rotational freedom | Limited angular displacement |

| Precision | Moderate, affected by wear | High, no backlash or friction |

| Load Capacity | Supports heavy loads | Suitable for low to moderate loads |

| Maintenance | Requires lubrication and part replacement | Maintenance-free, no moving parts |

| Durability | Subject to wear and fatigue | High fatigue resistance if designed correctly |

| Applications | Robotic arms, precision instruments | Micro-robotics, compliant mechanisms |

Introduction to Ball Bearing and Flexure Joints

Ball bearing joints utilize rolling elements to reduce friction and support radial and axial loads, offering precise rotational motion in machinery and robotics. Flexure joints rely on the elastic deformation of materials to provide smooth, frictionless movement with high repeatability, making them ideal for precision applications requiring minimal maintenance. Your choice between ball bearing and flexure joints depends on factors like load capacity, motion accuracy, and environmental conditions.

Fundamental Working Principles

Ball bearing joints operate using rolling elements that reduce friction between moving parts, enabling smooth rotation and precise angular movement with minimal resistance. Flexure joints rely on the elastic deformation of flexible elements, allowing motion through bending or twisting while maintaining structural integrity without traditional bearings. Your choice between these joints depends on application requirements such as load capacity, precision, and range of motion.

Design and Structural Differences

Ball bearing joints feature rolling elements that reduce friction and accommodate rotational motion through steel balls housed between inner and outer races, allowing precise movement with minimal wear. Flexure joints rely on elastic deformation of compliant materials or thin beams to enable motion without traditional bearings, offering smooth, frictionless movement with inherent damping but limited range and load capacity. Structural differences highlight that ball bearing joints incorporate discrete components and require lubrication, while flexure joints are monolithic, free from mechanical contact surfaces, and designed for high-precision applications with small angular displacements.

Load Capacity and Performance

Ball bearing joints offer higher load capacity and durability under dynamic loads due to rolling elements minimizing friction and wear, making them ideal for applications with heavy or varying loads. Flexure joints provide precise, frictionless motion with limited load capacity, as they rely on material deformation, which suits applications requiring high positional accuracy and smooth performance under lighter loads. Your choice depends on whether load capacity or precision performance is the primary requirement for your mechanism.

Range of Motion and Flexibility

Ball bearing joints offer a wide range of motion with low friction, enabling smooth rotational movement and high flexibility in multiple directions. Flexure joints provide limited range of motion but excel in precision and repeatability due to their elastic deformation, making them ideal for micro-scale applications. The choice depends on the required balance between extensive mobility and fine mechanical control.

Durability and Maintenance Requirements

Ball bearing joints offer high durability with robust metal components designed to withstand heavy loads and continuous motion, though they require regular lubrication and periodic inspection to prevent wear and corrosion. Flexure joints, made from flexible materials or precision-machined metals, provide maintenance-free operation by eliminating friction and wear points but may have limited lifespan under cyclic stress due to material fatigue. The choice between these joints depends on balancing long-term durability with maintenance availability and the specific application's load and motion dynamics.

Vibration Damping and Noise Characteristics

Ball bearing joints provide low friction and smooth rotation but tend to transmit vibrations and generate noise due to metal-on-metal contact, making them less effective for vibration damping. Flexure joints, constructed from elastic materials, excel in vibration damping by absorbing and dissipating energy through material deformation, resulting in quieter operation with minimal mechanical noise. Your choice between these joints should consider the specific application's noise sensitivity and vibration reduction requirements to optimize performance.

Cost and Manufacturing Considerations

Ball bearing joints typically incur higher costs due to precision machining, assembly complexity, and the need for lubricants, making them less ideal for budget-sensitive projects. Flexure joints, with their simpler solid-state design and fewer components, often reduce manufacturing time and expenses, benefiting mass production and applications requiring minimal maintenance. Material selection and tolerance control in flexure joints further streamline fabrication, offering cost advantages over ball bearing joints in many industrial scenarios.

Typical Applications and Industries

Ball bearing joints are commonly employed in automotive steering systems, robotics, and aerospace mechanisms where precise rotational movement and load handling are critical. Flexure joints find extensive use in precision instruments, microelectromechanical systems (MEMS), and optical devices due to their frictionless motion and ability to accommodate small angular displacements without backlash. Industries such as manufacturing automation, medical devices, and semiconductor fabrication leverage flexure joints for high-accuracy alignment, while ball bearing joints dominate in heavy machinery and transportation sectors requiring robust load support.

Pros, Cons, and Selection Guidelines

Ball bearing joints offer high load capacity and low friction, making them ideal for applications requiring smooth rotational movement and durability under heavy loads. However, they can suffer from wear and require regular maintenance, whereas flexure joints provide frictionless, backlash-free motion with excellent precision but are limited by smaller load capacities and potential material fatigue over time. Your selection should depend on application-specific requirements such as load magnitude, desired accuracy, maintenance capabilities, and motion range to optimize performance and longevity.

Ball Bearing Joint vs Flexure Joint Infographic

libmatt.com

libmatt.com