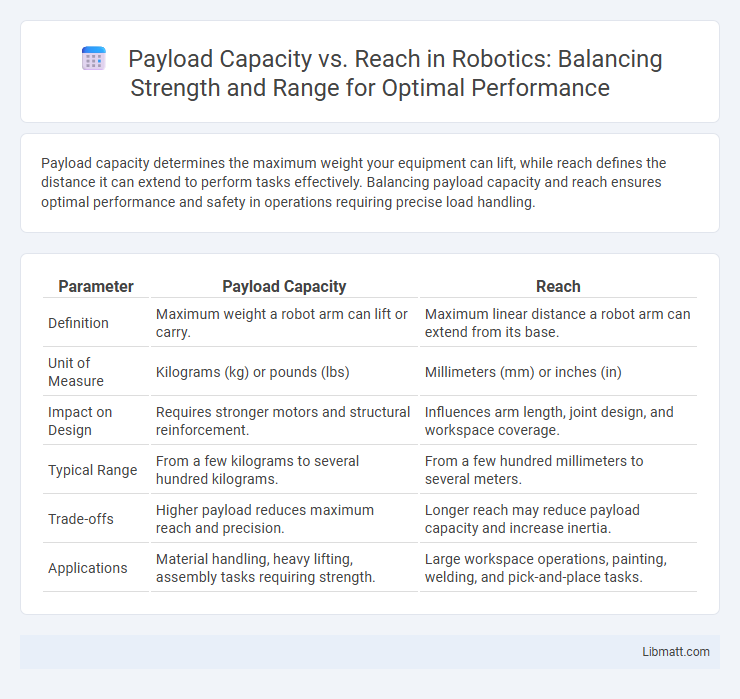

Payload capacity determines the maximum weight your equipment can lift, while reach defines the distance it can extend to perform tasks effectively. Balancing payload capacity and reach ensures optimal performance and safety in operations requiring precise load handling.

Table of Comparison

| Parameter | Payload Capacity | Reach |

|---|---|---|

| Definition | Maximum weight a robot arm can lift or carry. | Maximum linear distance a robot arm can extend from its base. |

| Unit of Measure | Kilograms (kg) or pounds (lbs) | Millimeters (mm) or inches (in) |

| Impact on Design | Requires stronger motors and structural reinforcement. | Influences arm length, joint design, and workspace coverage. |

| Typical Range | From a few kilograms to several hundred kilograms. | From a few hundred millimeters to several meters. |

| Trade-offs | Higher payload reduces maximum reach and precision. | Longer reach may reduce payload capacity and increase inertia. |

| Applications | Material handling, heavy lifting, assembly tasks requiring strength. | Large workspace operations, painting, welding, and pick-and-place tasks. |

Understanding Payload Capacity and Reach

Payload capacity refers to the maximum weight a device or vehicle can safely carry, while reach indicates the maximum distance it can extend or operate effectively. Balancing payload capacity and reach is crucial for optimizing performance in cranes, drones, and robotic arms, ensuring tasks are completed safely and efficiently. Understanding these factors helps you select equipment that meets operational demands without compromising stability or control.

The Importance of Payload Capacity in Robotics

Payload capacity in robotics directly influences the types of tasks a robot can perform efficiently, determining its ability to carry, lift, or manipulate objects within its operational environment. High payload capacity enables robots to handle heavier materials and tools, essential for industries such as manufacturing, logistics, and construction. Optimizing payload capacity enhances productivity, reduces the need for multiple robotic units, and increases the overall versatility of robotic systems.

How Reach Impacts Robotic Applications

Reach significantly influences robotic applications by determining the operational range within which a robot can manipulate objects or perform tasks, directly affecting efficiency and flexibility. A greater reach allows robots to access wider workspaces without repositioning, essential in manufacturing, logistics, and assembly lines where spatial coverage is critical. However, extended reach often results in reduced payload capacity due to mechanical constraints, necessitating a balance between reach and load handling to optimize robot performance.

Payload vs Reach: Finding the Right Balance

Balancing payload capacity and reach is crucial for optimizing the efficiency of cranes, drones, or robotic arms in various industries. Higher payload capacities often result in reduced maximum reach due to increased structural and mechanical demands, while extended reach typically limits the weight that can be safely handled. Understanding the interplay between these factors ensures your equipment meets operational needs without compromising safety or performance.

Factors Affecting Payload Capacity

Payload capacity is influenced by factors such as the structural design, material strength, and weight distribution of the equipment or vehicle. Hydraulic systems, arm length, and mechanical leverage also play critical roles in determining how much weight can be safely lifted or carried without compromising stability. Environmental conditions and operational speed further affect the effective payload capacity during usage.

Determining Optimal Reach for Your Needs

Determining the optimal reach for your needs involves balancing payload capacity with the distance your equipment must cover. Longer reach often reduces the maximum payload a machine can safely handle due to mechanical and stability limitations. You should evaluate the specific weight requirements and operational distances to ensure your equipment delivers both the necessary reach and payload efficiency.

Industry Examples: Payload Capacity vs Reach

In the logistics industry, drones with high payload capacity are essential for transporting bulky goods over short distances, while those designed for extended reach enable delivery in remote or hard-to-access areas. Construction sites benefit from cranes and aerial lifts engineered to balance payload capacity with vertical and horizontal reach, optimizing material handling efficiency. In agriculture, sprayers with enhanced reach cover extensive crops quickly, but payload capacity limits the volume of pesticides or fertilizers applied per run.

Engineering Trade-offs Between Payload and Reach

Engineering trade-offs between payload capacity and reach often require balancing structural strength with arm length to maintain stability and performance in robotic systems or cranes. Increasing reach typically demands lighter materials or reinforced joints to avoid excessive torque and mechanical stress, which can reduce maximum payload capacity. Optimizing these factors ensures your equipment delivers the best combination of reach and load-handling capability without compromising safety or efficiency.

Choosing a Robot: Key Considerations

When choosing a robot, balancing payload capacity and reach is essential to match your specific application needs. Higher payload capacity allows the robot to handle heavier tools or materials, while greater reach ensures access to wider or more complex workspaces. Understanding your operational requirements helps optimize efficiency and productivity by selecting a robot designed to perform your tasks effectively.

Future Trends in Payload Capacity and Reach

Future trends in payload capacity and reach emphasize advancements in materials and propulsion technologies, enabling drones and delivery systems to transport heavier loads over greater distances efficiently. Innovations in lightweight composites and battery energy density improvements drive the expansion of payload weight limits while extending operational range. Your logistics and industrial operations will benefit significantly as these enhancements reduce delivery times and increase the scope of achievable tasks.

Payload Capacity vs Reach Infographic

libmatt.com

libmatt.com