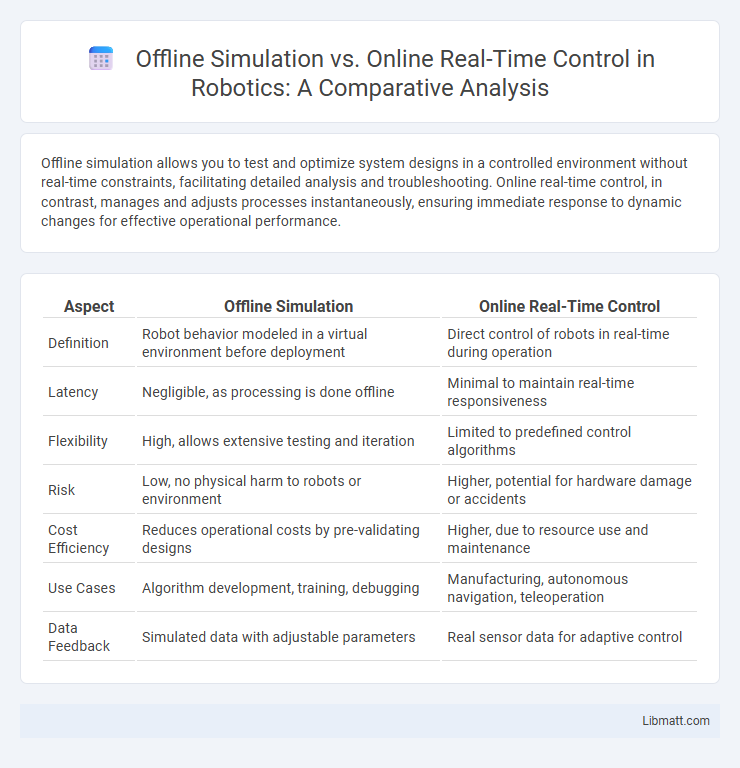

Offline simulation allows you to test and optimize system designs in a controlled environment without real-time constraints, facilitating detailed analysis and troubleshooting. Online real-time control, in contrast, manages and adjusts processes instantaneously, ensuring immediate response to dynamic changes for effective operational performance.

Table of Comparison

| Aspect | Offline Simulation | Online Real-Time Control |

|---|---|---|

| Definition | Robot behavior modeled in a virtual environment before deployment | Direct control of robots in real-time during operation |

| Latency | Negligible, as processing is done offline | Minimal to maintain real-time responsiveness |

| Flexibility | High, allows extensive testing and iteration | Limited to predefined control algorithms |

| Risk | Low, no physical harm to robots or environment | Higher, potential for hardware damage or accidents |

| Cost Efficiency | Reduces operational costs by pre-validating designs | Higher, due to resource use and maintenance |

| Use Cases | Algorithm development, training, debugging | Manufacturing, autonomous navigation, teleoperation |

| Data Feedback | Simulated data with adjustable parameters | Real sensor data for adaptive control |

Introduction to Offline Simulation and Online Real-Time Control

Offline simulation involves testing and analyzing system models in a controlled environment without live data, enabling design verification and performance evaluation before deployment. Online real-time control processes live sensor inputs and system feedback instantly to adjust operations dynamically, ensuring optimal performance and responsiveness. Combining both approaches enhances system reliability by leveraging comprehensive pre-testing and adaptive real-time adjustments.

Defining Offline Simulation: Key Characteristics

Offline simulation involves creating detailed mathematical models to replicate physical systems without interacting with live hardware, enabling thorough testing under varied scenarios. Key characteristics include the ability to perform extensive what-if analyses, risk-free environment for validating control algorithms, and time flexibility since simulations are not constrained by real-time requirements. Your development process benefits from increased safety and cost-efficiency by detecting potential issues before deploying control strategies in online real-time systems.

Understanding Online Real-Time Control Systems

Online real-time control systems process sensor data instantly to make immediate decisions, ensuring rapid responses in dynamic environments like autonomous vehicles and industrial automation. These systems rely on continuous feedback loops and high-speed communication networks to maintain stability and accuracy under varying conditions. Emphasizing latency minimization and synchronization, online control systems outperform offline simulations by adapting to real-world disturbances in real time.

Core Differences Between Offline and Online Approaches

Offline simulation involves pre-computing system responses based on historical data, enabling detailed analysis without real-time constraints, while online real-time control processes live data to make immediate adjustments and maintain system stability. The core difference lies in timing: offline simulations offer comprehensive scenario testing without direct interaction, whereas online control requires instantaneous decision-making to respond dynamically to changing conditions. Your choice depends on whether predictive accuracy or adaptive responsiveness is critical for your application.

Advantages of Offline Simulation in Engineering

Offline simulation in engineering enables thorough testing and validation of complex systems without the risk of damaging actual hardware, significantly reducing development costs. It allows engineers to explore multiple design scenarios and optimize parameters efficiently before real-world implementation. This approach enhances accuracy in predicting system behavior under diverse conditions, ultimately improving reliability and performance.

Benefits of Online Real-Time Control for Modern Applications

Online real-time control enables instant data processing and immediate system response, enhancing precision and adaptability in dynamic environments such as autonomous vehicles and industrial automation. This approach supports continuous monitoring and rapid decision-making, reducing downtime and improving overall system efficiency. By integrating real-time feedback, modern applications can optimize performance, ensure safety, and accommodate variable conditions more effectively than offline simulation.

Challenges and Limitations of Offline Simulation

Offline simulation faces significant challenges such as limited accuracy in replicating real-time system dynamics and the inability to account for unforeseen environmental changes or hardware malfunctions. The delay between simulation results and actual implementation reduces responsiveness, making it difficult to address real-time disturbances or system degradation effectively. Furthermore, offline models often lack the granularity required for precise control decisions, leading to suboptimal performance when deployed in live environments.

Issues and Constraints in Online Real-Time Control

Online real-time control faces challenges such as limited computational resources and strict timing constraints, requiring immediate processing of sensor data to ensure system stability and responsiveness. Network latency, data packet loss, and unpredictable environmental disturbances further complicate real-time decision-making, potentially causing delays or errors in control commands. Your system must balance accuracy and speed, often relying on simplified models and robust algorithms to maintain performance under these constraints.

Use Cases: When to Choose Offline vs. Online Control

Offline simulation is ideal for testing complex scenarios, optimizing system parameters, and validating algorithms without risking real-world consequences, making it suitable for development and training phases. Online real-time control is essential when immediate system responses are required, such as in autonomous vehicles, robotics, or industrial automation, where continuous feedback and adaptation to dynamic conditions are critical. You should choose offline simulation to refine strategies safely and switch to online real-time control when deployment demands instant decision-making and responsiveness.

Future Trends and Integration of Simulation and Real-Time Systems

Future trends in offline simulation and online real-time control emphasize the seamless integration of digital twins with adaptive algorithms to enhance predictive accuracy and operational responsiveness. Advances in edge computing and 5G technology enable real-time data processing and low-latency feedback loops, marrying high-fidelity simulation with instantaneous control actions. The convergence of AI-driven models and real-time sensor data is paving the way for autonomous systems that self-optimize continuously across diverse industrial applications.

Offline Simulation vs Online Real-Time Control Infographic

libmatt.com

libmatt.com