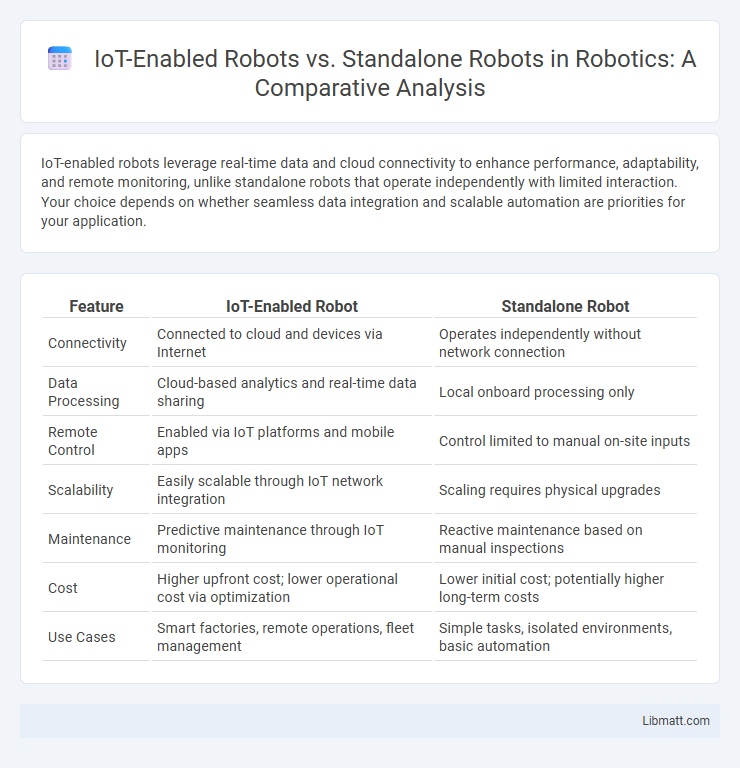

IoT-enabled robots leverage real-time data and cloud connectivity to enhance performance, adaptability, and remote monitoring, unlike standalone robots that operate independently with limited interaction. Your choice depends on whether seamless data integration and scalable automation are priorities for your application.

Table of Comparison

| Feature | IoT-Enabled Robot | Standalone Robot |

|---|---|---|

| Connectivity | Connected to cloud and devices via Internet | Operates independently without network connection |

| Data Processing | Cloud-based analytics and real-time data sharing | Local onboard processing only |

| Remote Control | Enabled via IoT platforms and mobile apps | Control limited to manual on-site inputs |

| Scalability | Easily scalable through IoT network integration | Scaling requires physical upgrades |

| Maintenance | Predictive maintenance through IoT monitoring | Reactive maintenance based on manual inspections |

| Cost | Higher upfront cost; lower operational cost via optimization | Lower initial cost; potentially higher long-term costs |

| Use Cases | Smart factories, remote operations, fleet management | Simple tasks, isolated environments, basic automation |

Introduction to IoT-Enabled Robots and Standalone Robots

IoT-enabled robots leverage interconnected sensors and cloud computing to perform tasks with real-time data exchange and remote control, enhancing adaptability and efficiency. In contrast, standalone robots operate independently using onboard systems without external data input, limiting their responsiveness to dynamic environments. Your choice between these robots depends on whether continuous connectivity and data integration are critical for your application or if autonomous operation is a priority.

Core Differences Between IoT and Standalone Robots

IoT-enabled robots integrate with cloud networks and IoT platforms to enable real-time data sharing, remote monitoring, and adaptive learning, while standalone robots operate independently without network connectivity or external data exchange. The core difference lies in connectivity: IoT robots leverage sensors and internet protocols to improve efficiency and decision-making through continuous feedback loops, whereas standalone robots rely solely on pre-programmed instructions and embedded processing. This connectivity in IoT robots enhances scalability, predictive maintenance, and interoperability across multiple devices, contrasting the isolated functionality of standalone robots.

Connectivity and Communication Capabilities

IoT-enabled robots leverage advanced connectivity protocols such as Wi-Fi, Bluetooth, and 5G to enable real-time communication with cloud platforms, other devices, and data analytics systems, enhancing operational efficiency and remote monitoring. Standalone robots operate independently, utilizing onboard sensors and processors with limited or no external communication, restricting adaptability and collaborative functions. The integration of IoT connectivity in robots facilitates seamless data exchange, predictive maintenance, and scalable automation solutions.

Data Collection and Real-Time Analytics

IoT-enabled robots leverage interconnected sensors and cloud platforms to collect extensive data streams, enabling advanced real-time analytics that optimize performance and predictive maintenance. Standalone robots operate with limited onboard processing, restricting their ability to analyze data dynamically and adapt to changing conditions promptly. The integration of IoT enhances data aggregation and real-time decision-making far beyond the capabilities of isolated robotic systems.

Scalability and Integration Potential

IoT-enabled robots offer superior scalability through seamless integration with cloud platforms and IoT networks, enabling real-time data exchange and remote updates across multiple devices. Their connectivity allows for centralized management and coordination, which enhances operational efficiency and expands functionality through interoperability with other smart systems. In contrast, standalone robots have limited integration potential and scalability due to their isolated architecture, restricting their ability to adapt or expand within interconnected environments.

Deployment Flexibility and Use Cases

IoT-enabled robots offer superior deployment flexibility by leveraging cloud connectivity, enabling remote monitoring, real-time data exchange, and seamless integration with smart environments, which makes them ideal for dynamic applications like smart manufacturing and precision agriculture. Standalone robots operate independently without internet reliance, suited for controlled environments or isolated tasks such as simple assembly lines or hazardous inspections where network access is limited. Your choice between these depends on whether you prioritize adaptive, connected operations or robust, autonomous functionality for specific industrial or commercial use cases.

Security and Privacy Considerations

IoT-enabled robots often face increased security and privacy risks due to constant connectivity and data exchange over networks, making them vulnerable to cyberattacks such as hacking, data breaches, and unauthorized access. Standalone robots, operating independently without internet connections, generally have a smaller attack surface and reduced exposure to remote exploits but still require robust internal security measures to prevent local tampering and data leakage. Implementing end-to-end encryption, secure authentication protocols, and regular software updates is critical for both types to safeguard sensitive information and maintain operational integrity.

Maintenance, Updates, and Troubleshooting

IoT-enabled robots offer remote maintenance capabilities through real-time data monitoring, enabling predictive analytics to detect issues before failures occur, significantly reducing downtime. Software updates for IoT robots can be deployed over-the-air, ensuring continuous improvements and security patches without physical intervention. In contrast, standalone robots require on-site maintenance and manual updates, often leading to longer troubleshooting times due to limited diagnostic visibility and absence of connectivity for remote support.

Cost Implications and Resource Optimization

IoT-enabled robots leverage network connectivity to optimize resource allocation, reducing operational costs through real-time data analytics and remote management. Standalone robots, while having lower initial setup expenses, often incur higher maintenance costs due to limited monitoring capabilities and less efficient resource use. Your choice impacts long-term cost efficiency, with IoT-enabled solutions typically offering better scalability and optimized utilization of materials and energy.

Future Trends: Evolving Roles of Robots

Future trends in robotics highlight IoT-enabled robots as increasingly interconnected devices, capable of real-time data sharing and collective decision-making, vastly enhancing efficiency and adaptability across industries. Standalone robots, operating independently without network integration, will continue to excel in controlled environments where reliability and simplicity are paramount. Your choice between IoT-enabled and standalone robots should align with evolving roles emphasizing connectivity, predictive maintenance, and collaborative automation in smart ecosystems.

IoT-enabled robot vs Standalone robot Infographic

libmatt.com

libmatt.com