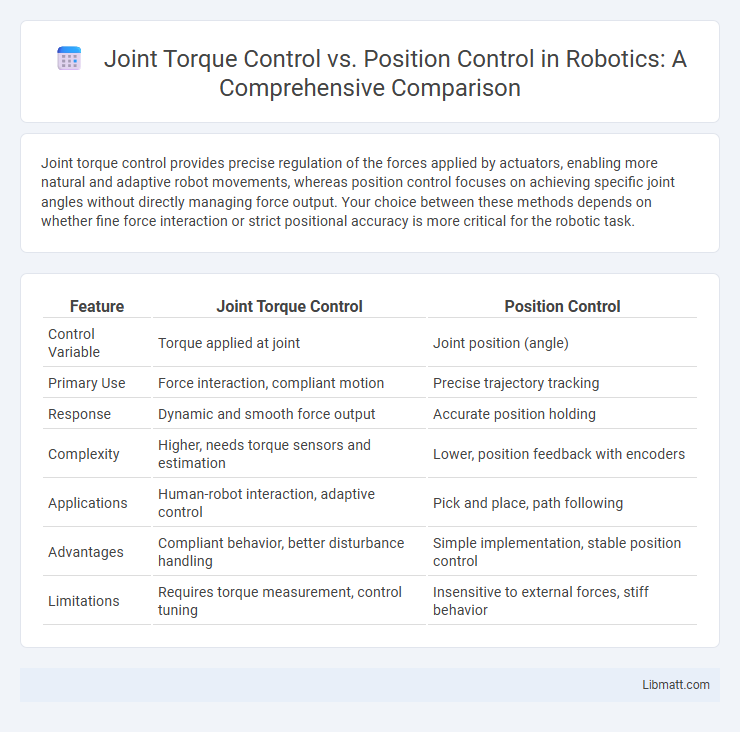

Joint torque control provides precise regulation of the forces applied by actuators, enabling more natural and adaptive robot movements, whereas position control focuses on achieving specific joint angles without directly managing force output. Your choice between these methods depends on whether fine force interaction or strict positional accuracy is more critical for the robotic task.

Table of Comparison

| Feature | Joint Torque Control | Position Control |

|---|---|---|

| Control Variable | Torque applied at joint | Joint position (angle) |

| Primary Use | Force interaction, compliant motion | Precise trajectory tracking |

| Response | Dynamic and smooth force output | Accurate position holding |

| Complexity | Higher, needs torque sensors and estimation | Lower, position feedback with encoders |

| Applications | Human-robot interaction, adaptive control | Pick and place, path following |

| Advantages | Compliant behavior, better disturbance handling | Simple implementation, stable position control |

| Limitations | Requires torque measurement, control tuning | Insensitive to external forces, stiff behavior |

Introduction to Joint Torque Control and Position Control

Joint torque control directly regulates the torque output of each actuator, enabling precise manipulation of force and improved interaction with dynamic environments, essential for tasks requiring adaptability and compliance. Position control, on the other hand, focuses on achieving specific joint angles by commanding setpoint positions, which is effective for accurate trajectory tracking but less responsive to external disturbances. Understanding the fundamental differences between these approaches is critical for selecting the appropriate control strategy in robotic manipulation and automation applications.

Fundamental Differences Between Torque and Position Control

Joint torque control directly modulates the force output at the joint, allowing precise regulation of interaction forces and compliance with the environment, whereas position control focuses on achieving and maintaining a specific joint angle or trajectory. Torque control adapts dynamically to external disturbances by adjusting torque in real-time, enhancing safety and performance in tasks requiring delicate force management. Your choice between these methods influences the robot's responsiveness, accuracy, and ability to perform force-sensitive operations.

Key Principles of Joint Torque Control

Joint Torque Control relies on directly regulating the torque applied at the robot's joints, enabling compliant and adaptive interaction with dynamic environments by modulating force rather than position. This control method utilizes torque sensors and feedback loops to adjust joint efforts precisely, enhancing safety and efficiency in tasks requiring variable stiffness or force, such as assembly or human-robot collaboration. By focusing on torque commands, it allows robots to perform delicate operations with improved accuracy and responsiveness compared to traditional position control systems.

Key Principles of Position Control

Position control operates by commanding precise joint angles, using feedback loops from encoders to minimize error between desired and actual positions. This method prioritizes accuracy in achieving specific angular targets, making it ideal for tasks requiring exact positioning of robotic arms or machinery. Your system's stability depends largely on tuning the proportional-integral-derivative (PID) controller parameters to respond effectively to disturbances and maintain set positions.

Advantages of Joint Torque Control in Robotics

Joint Torque Control in robotics enables precise force application and compliant interaction with the environment, improving adaptability in unstructured tasks and enhancing safety during human-robot collaboration. It allows dynamic adjustment of joint torques, resulting in smoother motion and better disturbance rejection compared to position control. This control strategy optimizes energy efficiency and increases task accuracy by directly regulating torque rather than relying on predefined joint positions.

Benefits and Limitations of Position Control

Position control offers precise tracking of desired trajectories by directly regulating joint angles, making it ideal for applications requiring accurate path following and repeatability. Its simplicity and ease of implementation reduce computational complexity and enhance system stability under predictable load conditions. However, position control struggles with adapting to variable external forces and lacks inherent compliance, often leading to poor performance in tasks involving interaction with unpredictable environments or requiring force sensitivity.

Application Scenarios for Torque vs Position Control

Joint torque control excels in applications requiring precise force interaction and compliance, such as robotic manipulation, haptics, and physical human-robot interaction, where adaptability to external forces is crucial. Position control is better suited for applications demanding accurate joint positioning and trajectory tracking, like CNC machines, pick-and-place robots, and automated assembly lines. Your choice between torque and position control depends on whether force adaptability or precise movement execution is the priority in your robotic system.

Performance Comparison: Precision, Speed, and Adaptability

Joint torque control offers superior precision in force application and adaptability to varying load conditions, making it ideal for tasks requiring delicate interaction or compliance. Position control excels in achieving high-speed and repeatable motions, providing consistent accuracy in predefined trajectories with minimal computational complexity. Your choice depends on whether precise force modulation or rapid, accurate positioning is more critical for your robotic application.

Challenges in Implementing Joint Torque and Position Control

Implementing joint torque control poses challenges such as accurately sensing and regulating force output, requiring high-fidelity sensors and rapid feedback loops to maintain stability during dynamic interactions. Position control struggles with compensating for external disturbances and system nonlinearities, often resulting in overshoot or oscillations that affect precision. Your robotic system must balance these trade-offs by carefully tuning control algorithms to ensure smooth, responsive motion under varying operational conditions.

Future Trends in Robotic Joint Control Techniques

Future trends in robotic joint control techniques emphasize advanced machine learning algorithms for adaptive joint torque control, enhancing real-time responsiveness and energy efficiency. Integration of sensor fusion technologies enables precise force feedback, improving manipulation accuracy over traditional position control methods. Research advances also explore hybrid control systems that combine torque and position strategies to optimize performance in dynamic and unstructured environments.

Joint Torque Control vs Position Control Infographic

libmatt.com

libmatt.com