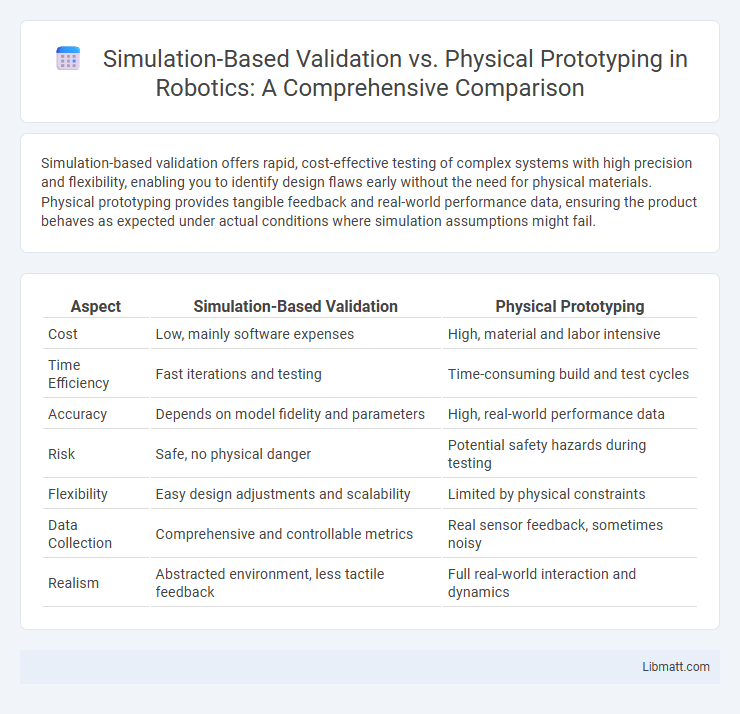

Simulation-based validation offers rapid, cost-effective testing of complex systems with high precision and flexibility, enabling you to identify design flaws early without the need for physical materials. Physical prototyping provides tangible feedback and real-world performance data, ensuring the product behaves as expected under actual conditions where simulation assumptions might fail.

Table of Comparison

| Aspect | Simulation-Based Validation | Physical Prototyping |

|---|---|---|

| Cost | Low, mainly software expenses | High, material and labor intensive |

| Time Efficiency | Fast iterations and testing | Time-consuming build and test cycles |

| Accuracy | Depends on model fidelity and parameters | High, real-world performance data |

| Risk | Safe, no physical danger | Potential safety hazards during testing |

| Flexibility | Easy design adjustments and scalability | Limited by physical constraints |

| Data Collection | Comprehensive and controllable metrics | Real sensor feedback, sometimes noisy |

| Realism | Abstracted environment, less tactile feedback | Full real-world interaction and dynamics |

Introduction to Validation in Product Development

Simulation-based validation leverages virtual models and computer algorithms to predict product performance, enabling rapid iteration and cost-effective testing during product development. Physical prototyping involves creating tangible models to observe real-world behavior, providing direct insights but often requiring more time and higher expenses. Combining both methods enhances accuracy in validation, reduces risks, and accelerates the overall development cycle.

Defining Simulation-Based Validation

Simulation-based validation uses virtual models to test and analyze product performance under various conditions, significantly reducing time and costs compared to physical prototyping. This method allows for early detection of design flaws, optimization of parameters, and iterative improvements without the need for manufacturing actual prototypes. You benefit from faster development cycles and increased accuracy in predicting real-world behavior through advanced computational tools.

Understanding Physical Prototyping

Physical prototyping involves creating tangible models to test and validate product designs under real-world conditions, offering direct feedback on functionality, durability, and usability. This approach helps identify manufacturing issues and user experience challenges that might be overlooked in simulation-based validation. Your ability to physically interact with prototypes ensures a practical assessment, bridging the gap between theoretical models and actual product performance.

Key Differences Between Simulation and Physical Prototyping

Simulation-based validation relies on digital models to predict product behavior under various conditions, offering rapid iteration and cost-efficiency without the need for physical materials. Physical prototyping involves building tangible models to directly assess real-world performance, capturing complex interactions and unforeseen issues that simulations may miss. Key differences include simulation's ability to quickly modify parameters and analyze scenarios versus physical prototyping's strength in providing empirical validation and hands-on testing.

Advantages of Simulation-Based Validation

Simulation-based validation offers faster testing cycles and significant cost savings compared to physical prototyping by eliminating the need for multiple physical models. It enables early detection of design flaws through virtual environments, increasing overall product reliability and reducing time-to-market. Your engineering team can optimize designs more efficiently using detailed analytics and scenario variations impossible to replicate physically.

Benefits of Physical Prototyping

Physical prototyping provides tangible evaluation of product designs, allowing for direct assessment of ergonomics, material properties, and assembly processes. It enables detection of unforeseen issues related to real-world conditions such as wear, stress, and environmental interactions, which simulation models might overlook. This hands-on approach facilitates immediate feedback from stakeholders and end-users, enhancing iterative design improvements and ensuring product reliability before mass production.

Cost and Time Considerations

Simulation-based validation significantly reduces both cost and time by allowing virtual testing and iteration without the need for expensive materials or manufacturing processes. Physical prototyping incurs higher expenses due to raw material costs, labor, and machine time, often extending project timelines through iterative build and test cycles. Leveraging simulation can optimize your development process by accelerating validation while minimizing financial investment.

Accuracy and Realism: Simulation vs Physical Testing

Simulation-based validation offers precise control over variables and allows rapid iteration, providing detailed insights through computational models that reproduce real-world scenarios with high accuracy. Physical prototyping delivers unmatched realism by testing actual materials and components under real environmental conditions, capturing complex interactions and unforeseen issues. Combining both approaches enhances design validation by balancing the high fidelity of physical tests with the flexibility and cost-efficiency of simulations.

Hybrid Approaches: Combining Simulation and Prototyping

Hybrid approaches integrating simulation-based validation with physical prototyping leverage the strengths of both methods to enhance product development accuracy and efficiency. By using advanced CFD simulations and finite element analysis alongside rapid prototyping techniques, engineers can iteratively refine designs before committing to costly physical builds. This combination reduces time-to-market and improves reliability by allowing real-world testing to validate and adjust simulation models continuously.

Future Trends in Validation Methods

Simulation-based validation is increasingly leveraging artificial intelligence and machine learning to enhance predictive accuracy and reduce development cycles, enabling complex system evaluations in virtual environments. Physical prototyping continues to evolve with advancements in additive manufacturing and sensor integration, allowing for rapid iteration and real-time performance monitoring. Emerging hybrid approaches combine digital twins with physical tests to optimize validation processes, improve reliability, and lower costs in industries such as automotive and aerospace.

Simulation-based validation vs Physical prototyping Infographic

libmatt.com

libmatt.com