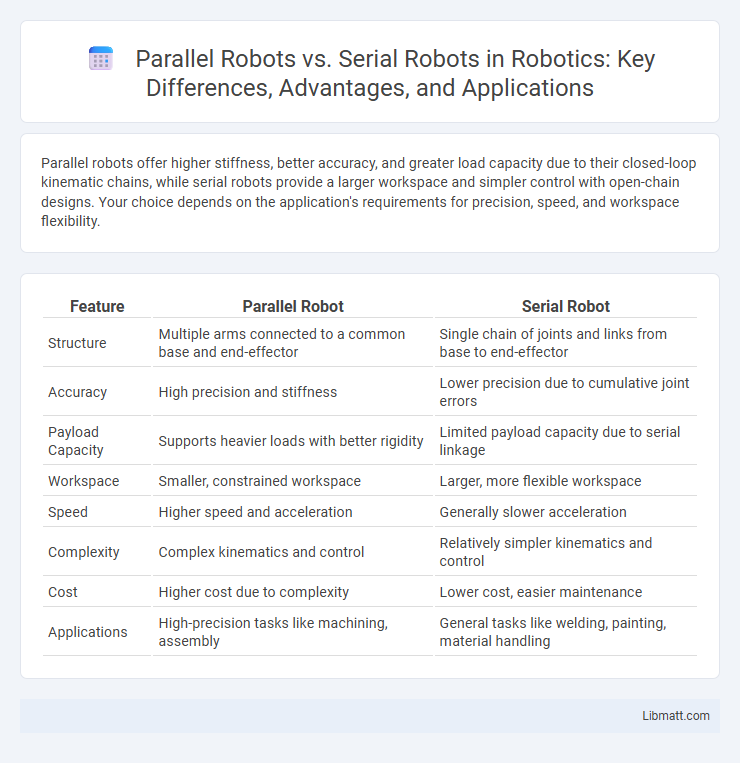

Parallel robots offer higher stiffness, better accuracy, and greater load capacity due to their closed-loop kinematic chains, while serial robots provide a larger workspace and simpler control with open-chain designs. Your choice depends on the application's requirements for precision, speed, and workspace flexibility.

Table of Comparison

| Feature | Parallel Robot | Serial Robot |

|---|---|---|

| Structure | Multiple arms connected to a common base and end-effector | Single chain of joints and links from base to end-effector |

| Accuracy | High precision and stiffness | Lower precision due to cumulative joint errors |

| Payload Capacity | Supports heavier loads with better rigidity | Limited payload capacity due to serial linkage |

| Workspace | Smaller, constrained workspace | Larger, more flexible workspace |

| Speed | Higher speed and acceleration | Generally slower acceleration |

| Complexity | Complex kinematics and control | Relatively simpler kinematics and control |

| Cost | Higher cost due to complexity | Lower cost, easier maintenance |

| Applications | High-precision tasks like machining, assembly | General tasks like welding, painting, material handling |

Introduction to Parallel and Serial Robots

Parallel robots consist of multiple arms connected to a single base and end-effector, providing high stiffness, precision, and load-carrying capacity, making them ideal for applications requiring speed and accuracy like flight simulators and CNC machining. Serial robots feature a single articulated arm with multiple joints arranged in a chain, offering a larger workspace and greater flexibility, commonly used in assembly lines, welding, and painting tasks. The fundamental structural difference influences their kinematics, payload capabilities, and suitability for specific industrial tasks.

Fundamental Differences Between Parallel and Serial Robots

Parallel robots feature multiple arms connected to a single base, enabling higher stiffness, precision, and load capacity compared to serial robots, which have a single arm with joints arranged in series allowing greater reach and flexibility. Parallel robots operate with closed-loop kinematics providing enhanced speed and accuracy for tasks like machining and assembly, while serial robots rely on open-loop kinematics suitable for complex, multi-axis movements. The fundamental difference lies in their structural configuration: parallel robots distribute loads across multiple limbs, whereas serial robots bear loads sequentially along the arm, affecting their performance and application suitability.

Structural Design and Configuration Comparison

Parallel robots feature a closed-loop kinematic structure where multiple arms simultaneously connect the base to the end-effector, offering higher stiffness and precision. Serial robots have an open-chain configuration with a sequence of joints and links extending from the base to the end-effector, allowing a larger work envelope and greater reach. The structural design of parallel robots results in lower payload capacity and complexity in control compared to the simpler, more versatile serial robot configurations used in diverse industrial applications.

Workspace and Range of Motion Analysis

Parallel robots offer a more constrained workspace but provide higher stiffness and precision, making them ideal for tasks requiring limited but highly controlled range of motion. Serial robots feature larger workspaces with greater flexibility and extended range of motion, suitable for complex, multi-directional operations. Your choice depends on the required balance between precision within a compact range and extensive maneuverability across varied positions.

Precision and Accuracy in Parallel vs Serial Robots

Parallel robots offer higher precision and accuracy due to their closed-loop kinematic structure, which minimizes cumulative errors and improves stiffness. Serial robots, with their open-chain configuration, typically experience greater positional errors caused by joint compliance and accumulated tolerances along the arm. The superior rigidity and load distribution in parallel robots make them ideal for applications requiring meticulous motion control and repeatability.

Load Capacity and Payload Performance

Parallel robots provide superior load capacity and payload performance due to their closed-loop kinematic structure, which distributes weight evenly across multiple arms. Serial robots, with their open-chain design, generally have lower load capacity and are better suited for lighter payloads and greater reach. Your choice depends on the application's need for precision and strength versus flexibility and range.

Speed and Dynamic Response Characteristics

Parallel robots exhibit superior speed and dynamic response characteristics compared to serial robots due to their closed-loop kinematic chains, which provide higher stiffness and lower moving mass. Your applications requiring rapid acceleration and precise motion control benefit from the enhanced rigidity and reduced inertia of parallel robots, enabling faster positioning and better vibration damping. Serial robots, while generally more flexible in reach and workspace, have slower dynamic responses due to cumulative joint compliance and greater moving masses.

Application Areas: Where Each Robot Excels

Parallel robots excel in high-precision tasks such as surgical operations, flight simulators, and CNC machining due to their rigid structure and superior load-bearing capacity. Serial robots dominate in versatile applications including assembly lines, welding, and material handling, benefiting from their larger workspace and greater flexibility. The choice between parallel and serial robots hinges on the specific requirements for precision, load, and range of motion in the target industry.

Cost Considerations and Maintenance Requirements

Parallel robots generally have higher initial costs due to their complex mechanical structure and precision manufacturing needs, but they often offer lower long-term maintenance expenses because of their rigid design and fewer moving parts. Serial robots tend to be more affordable upfront, benefiting from simpler construction, but they usually require more frequent maintenance and part replacements due to higher mechanical wear and increased joint complexity. Cost considerations between the two robot types should balance budget constraints with anticipated maintenance cycles and operational reliability demands.

Future Trends in Parallel and Serial Robotics

Future trends in parallel and serial robotics emphasize increased integration of AI-powered control systems and machine learning algorithms to enhance precision and adaptability in complex tasks. Parallel robots are evolving with advancements in lightweight materials and improved kinematic designs to achieve higher speed and stiffness for industrial automation. Serial robots focus on collaborative capabilities, incorporating sensor fusion and enhanced safety features to work seamlessly alongside humans in dynamic environments.

Parallel robot vs Serial robot Infographic

libmatt.com

libmatt.com