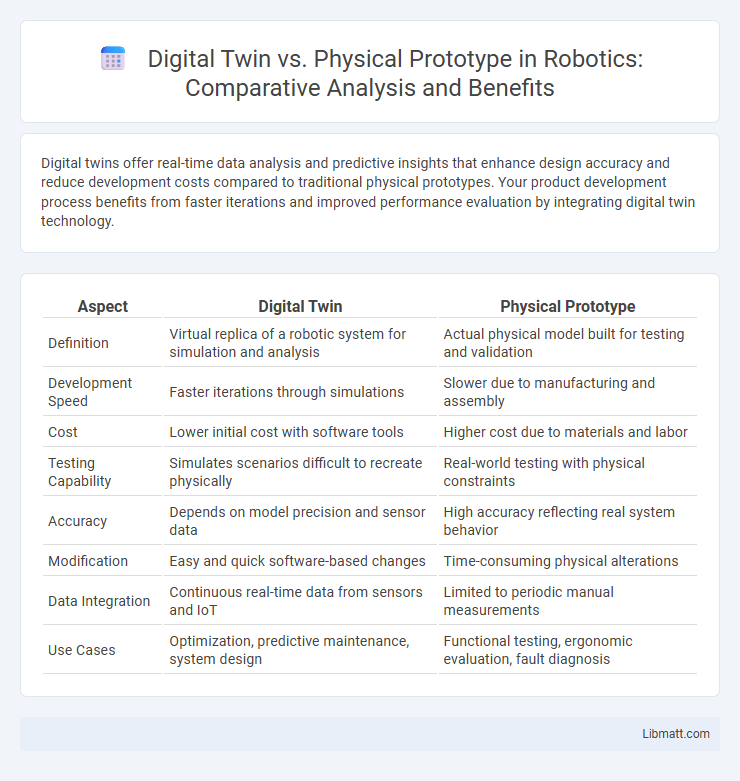

Digital twins offer real-time data analysis and predictive insights that enhance design accuracy and reduce development costs compared to traditional physical prototypes. Your product development process benefits from faster iterations and improved performance evaluation by integrating digital twin technology.

Table of Comparison

| Aspect | Digital Twin | Physical Prototype |

|---|---|---|

| Definition | Virtual replica of a robotic system for simulation and analysis | Actual physical model built for testing and validation |

| Development Speed | Faster iterations through simulations | Slower due to manufacturing and assembly |

| Cost | Lower initial cost with software tools | Higher cost due to materials and labor |

| Testing Capability | Simulates scenarios difficult to recreate physically | Real-world testing with physical constraints |

| Accuracy | Depends on model precision and sensor data | High accuracy reflecting real system behavior |

| Modification | Easy and quick software-based changes | Time-consuming physical alterations |

| Data Integration | Continuous real-time data from sensors and IoT | Limited to periodic manual measurements |

| Use Cases | Optimization, predictive maintenance, system design | Functional testing, ergonomic evaluation, fault diagnosis |

Introduction to Digital Twin and Physical Prototype

A Digital Twin is a dynamic, virtual replica of a physical object or system, continuously updated with real-time data to simulate its performance and behavior. A Physical Prototype is a tangible model used to test and validate design concepts before full-scale production, providing direct sensory feedback and real-world interaction. Your decision between these methods impacts the speed, cost, and accuracy of product development and testing.

Defining Digital Twin Technology

Digital Twin technology creates a virtual replica of physical assets, systems, or processes, enabling real-time monitoring, simulation, and analysis. Unlike physical prototypes, which require material resources and time for development, digital twins allow for rapid testing and optimization through data-driven models. This technology integrates IoT sensors, AI algorithms, and cloud computing to enhance predictive maintenance and operational efficiency.

What is a Physical Prototype?

A physical prototype is a tangible, real-world model created to test and validate design concepts, functionality, and usability before full-scale production. It allows engineers and designers to identify and correct flaws through hands-on examination and experimentation. Unlike digital twins, physical prototypes provide direct sensory feedback but often require more time and resources to develop and modify.

Key Differences between Digital Twin and Physical Prototype

A digital twin is a virtual replica of a physical asset that enables real-time monitoring, simulation, and predictive analysis, whereas a physical prototype is a tangible model used for hands-on testing and validation. Digital twins facilitate continuous data-driven insights and optimization throughout the product lifecycle, while physical prototypes primarily serve early-stage design verification and user experience evaluation. The contrast lies in the digital twin's dynamic data integration and scalability compared to the static, one-time use nature of physical prototypes.

Advantages of Digital Twins

Digital twins offer real-time data synchronization between virtual models and physical counterparts, enabling precise monitoring and predictive maintenance. They reduce costs and development time by allowing multiple design iterations and testing without the need for physical prototypes. Your product lifecycle benefits from enhanced decision-making accuracy, improved performance, and accelerated innovation through continuous virtual simulation and analysis.

Benefits of Physical Prototypes

Physical prototypes provide tangible, real-world testing environments that reveal practical assembly issues and material behaviors difficult to simulate digitally. They enable hands-on user experience evaluation, capturing ergonomic and aesthetic feedback critical for design refinement. Physical prototypes also allow immediate troubleshooting and iterative adjustments, enhancing product reliability before mass production.

Cost Comparison: Digital Twin vs Physical Prototype

Digital Twin technology significantly reduces costs compared to physical prototypes by eliminating material expenses, manufacturing time, and iterative build cycles. Your ability to simulate multiple scenarios and perform real-time adjustments digitally accelerates product development while minimizing resource wastage. Physical prototypes, meanwhile, require substantial investment in materials and labor, often leading to higher overall project costs and longer lead times.

Applications in Industry

Digital twins enable real-time monitoring, predictive maintenance, and performance optimization across industries such as manufacturing, automotive, and aerospace, reducing downtime and operational costs. Physical prototypes remain essential for tactile testing, ergonomic assessments, and validation of design concepts in sectors like consumer electronics and automotive safety. Combining digital twin technology with physical prototypes accelerates product development cycles and enhances innovation by integrating virtual simulations with hands-on experimentation.

Challenges and Limitations

Digital twins face challenges such as high initial implementation costs, data integration complexities, and the need for continuous real-time data updates to maintain accuracy. Physical prototypes, while tangible and straightforward for testing, are limited by longer development cycles, higher material costs, and difficulty simulating real-world dynamic conditions. Both approaches require balancing accuracy, cost, and scalability to optimize product development and performance validation.

Future Trends in Prototyping Technologies

Digital Twin technology is transforming prototyping by enabling real-time data simulation and predictive analytics, vastly improving design accuracy and reducing time-to-market. Physical prototypes remain essential for tactile testing and validation, but emerging trends show increased integration with digital twins for hybrid prototyping approaches. Your ability to leverage augmented reality and IoT sensors within digital twins will drive innovation and efficiency in future product development cycles.

Digital Twin vs Physical Prototype Infographic

libmatt.com

libmatt.com