CAN Bus offers robust, high-speed communication ideal for real-time control in automotive and industrial environments, while Modbus provides a simpler, widely-used protocol suited for connecting industrial electronic devices over serial or Ethernet networks. Your choice depends on whether you prioritize network speed and reliability (CAN Bus) or ease of integration and device compatibility (Modbus).

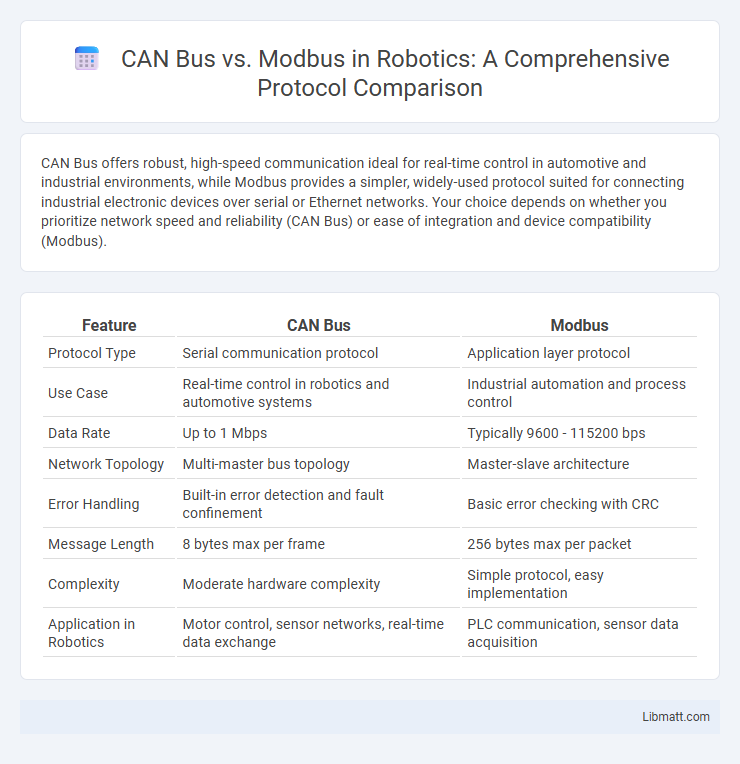

Table of Comparison

| Feature | CAN Bus | Modbus |

|---|---|---|

| Protocol Type | Serial communication protocol | Application layer protocol |

| Use Case | Real-time control in robotics and automotive systems | Industrial automation and process control |

| Data Rate | Up to 1 Mbps | Typically 9600 - 115200 bps |

| Network Topology | Multi-master bus topology | Master-slave architecture |

| Error Handling | Built-in error detection and fault confinement | Basic error checking with CRC |

| Message Length | 8 bytes max per frame | 256 bytes max per packet |

| Complexity | Moderate hardware complexity | Simple protocol, easy implementation |

| Application in Robotics | Motor control, sensor networks, real-time data exchange | PLC communication, sensor data acquisition |

Introduction to CAN Bus and Modbus

CAN Bus is a robust vehicle bus standard designed for real-time communication in automotive and industrial applications, enabling microcontrollers and devices to communicate without a host computer. Modbus is a serial communication protocol widely used in industrial automation systems for connecting electronic devices, supporting master-slave or client-server architectures over various physical media. Understanding the fundamental differences between CAN Bus and Modbus can help you choose the right protocol for your control and automation needs.

Communication Protocol Fundamentals

CAN Bus utilizes a multi-master, message-oriented protocol designed for robust communication in automotive and industrial environments, employing a priority-based arbitration method to manage data transmission. Modbus operates as a master-slave or client-server protocol, primarily used for serial communication in industrial automation systems, featuring simple command-response messaging and support for multiple function codes. Understanding these fundamental differences in communication structure and error handling can help you select the appropriate protocol for your control system needs.

Key Features of CAN Bus

CAN Bus offers robust error detection, real-time communication, and multi-master capabilities, making it ideal for automotive and industrial applications. Its message prioritization and fault confinement features ensure reliable data transfer under harsh conditions. You can leverage CAN Bus for efficient network management with minimal wiring and high noise immunity.

Key Features of Modbus

Modbus is an open, widely used communication protocol designed for industrial automation systems, supporting serial and TCP/IP networks. Its key features include simple master-slave architecture, ease of implementation, and compatibility with a diverse range of devices and controllers. Modbus provides reliable data exchange with standardized function codes for reading and writing registers and coils, making it ideal for monitoring and control applications in factories and process industries.

Network Topology Comparison

CAN Bus utilizes a bus topology where all nodes are connected to a single communication line, allowing for efficient real-time data exchange with minimal wiring complexity. Modbus commonly employs a star or line (daisy chain) topology, supporting serial (RS-232/RS-485) or TCP/IP networks, which can introduce greater latency and wiring overhead. The decentralized nature of CAN Bus improves fault tolerance and scalability, whereas Modbus networks rely more heavily on a central master device for communication control.

Data Transmission Methods

CAN Bus uses a multi-master, message-oriented transmission method where nodes communicate through a priority-based arbitration process, ensuring real-time data exchange with error detection and fault confinement. Modbus employs a master-slave communication protocol transferring data as discrete registers or coils via serial communication methods like RS-232, RS-485, or TCP/IP, prioritizing simplicity and ease of integration in industrial environments. The deterministic nature of CAN Bus suits high-speed, robust automotive and automation systems, whereas Modbus is preferred for slower, simpler device interactions requiring clear hierarchical control.

Application Areas: Industrial Use Cases

CAN Bus excels in automotive and manufacturing environments requiring real-time, high-speed communication among sensors and controllers, making it ideal for vehicle networks and factory automation. Modbus is widely used in industrial settings for monitoring and controlling equipment such as PLCs, SCADA systems, and process control, offering robust serial communication over longer distances. Your choice depends on the need for fast, reliable data exchange (CAN Bus) versus simpler, widely supported protocol integration (Modbus) in industrial applications.

Advantages of CAN Bus over Modbus

CAN Bus offers faster data transmission speeds up to 1 Mbps compared to Modbus's typical 115.2 kbps, enhancing real-time communication in automotive and industrial applications. Its multi-master architecture supports simultaneous device communication without a central controller, increasing network reliability and flexibility. CAN Bus also features robust error detection and fault confinement mechanisms that improve network stability and reduce downtime compared to Modbus's simpler error checking.

Advantages of Modbus over CAN Bus

Modbus offers broader compatibility with various industrial devices due to its simplicity and widespread adoption in automation systems. Your system benefits from easier implementation and troubleshooting, as Modbus uses a straightforward protocol with well-established standards. Unlike CAN Bus, Modbus supports longer-distance communication and can be integrated with Ethernet networks, enhancing flexibility in industrial environments.

Choosing the Right Protocol for Your Project

Selecting between CAN Bus and Modbus depends on the project's communication requirements and environment. CAN Bus offers robust real-time data transmission and error handling, ideal for automotive and industrial automation with high-speed, short-distance needs. Modbus suits applications requiring simple, asynchronous communication over longer distances with lower complexity, commonly found in building management and process control systems.

CAN Bus vs Modbus Infographic

libmatt.com

libmatt.com