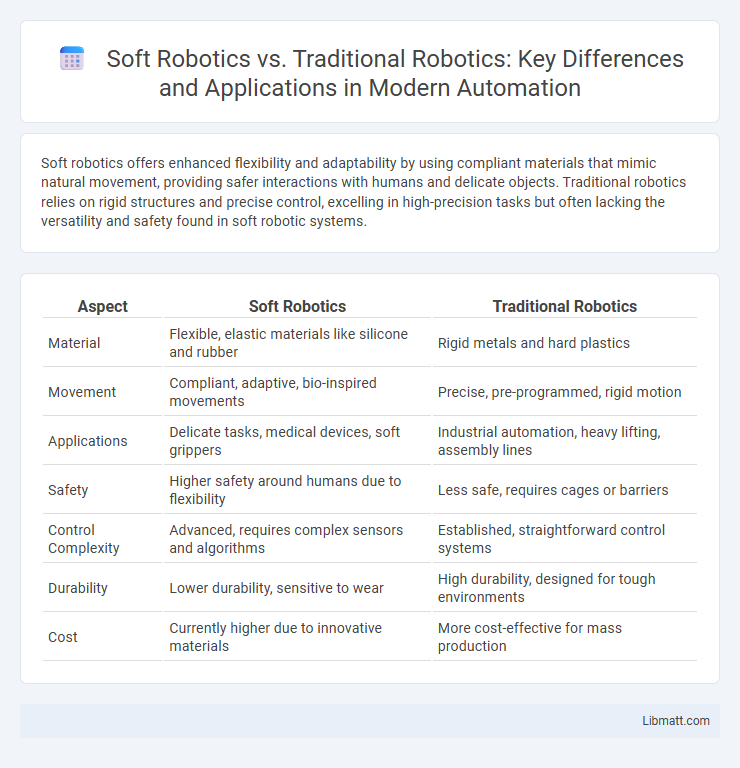

Soft robotics offers enhanced flexibility and adaptability by using compliant materials that mimic natural movement, providing safer interactions with humans and delicate objects. Traditional robotics relies on rigid structures and precise control, excelling in high-precision tasks but often lacking the versatility and safety found in soft robotic systems.

Table of Comparison

| Aspect | Soft Robotics | Traditional Robotics |

|---|---|---|

| Material | Flexible, elastic materials like silicone and rubber | Rigid metals and hard plastics |

| Movement | Compliant, adaptive, bio-inspired movements | Precise, pre-programmed, rigid motion |

| Applications | Delicate tasks, medical devices, soft grippers | Industrial automation, heavy lifting, assembly lines |

| Safety | Higher safety around humans due to flexibility | Less safe, requires cages or barriers |

| Control Complexity | Advanced, requires complex sensors and algorithms | Established, straightforward control systems |

| Durability | Lower durability, sensitive to wear | High durability, designed for tough environments |

| Cost | Currently higher due to innovative materials | More cost-effective for mass production |

Introduction to Soft Robotics and Traditional Robotics

Soft robotics employs flexible, compliant materials such as silicone and elastomers to mimic biological movements, enabling safer human-robot interaction and adaptability in unstructured environments. Traditional robotics relies on rigid components and precise mechanical structures, optimized for tasks requiring high strength, accuracy, and repeatability in controlled settings. The fundamental difference lies in actuation and design philosophy, with soft robotics emphasizing deformation and elasticity while traditional robotics focuses on rigidity and stability.

Core Principles of Soft Robotics

Soft robotics leverages compliant materials and bio-inspired designs to create flexible, adaptive robots that mimic natural movements, contrasting with traditional robotics' rigid structures and precise, pre-programmed motions. Core principles of soft robotics include the use of elastomers, sensors embedded within flexible matrices, and actuators like pneumatics or shape-memory alloys to achieve safe human-robot interaction and adaptability in unstructured environments. These innovations enable soft robots to perform delicate tasks in medical devices, agriculture, and search-and-rescue operations where traditional robots might fail due to stiffness and lack of adaptability.

Fundamental Technologies in Traditional Robotics

Traditional robotics relies heavily on rigid components such as metal frames, electric motors, and hydraulic actuators to achieve precise and stable movements. Sensors like encoders and gyroscopes enable accurate positioning and feedback control, while advanced control algorithms optimize robot performance in fixed environments. Your automation systems benefit from these fundamental technologies by ensuring reliability, repeatability, and high load-bearing capacity.

Flexibility and Adaptability Comparison

Soft robotics offers superior flexibility and adaptability compared to traditional robotics due to its use of compliant materials and bio-inspired designs that enable smooth, precise motions in unstructured environments. Traditional robotics, built with rigid components and predetermined movement patterns, often struggle with tasks requiring delicate handling or variable shapes. Your applications benefit from soft robotics' ability to conform and adapt dynamically, enhancing performance in sectors like healthcare, agriculture, and wearable devices.

Safety Considerations: Soft vs. Rigid Designs

Soft robotics prioritize safety with flexible, compliant materials that reduce the risk of injury during human interaction, making them ideal for sensitive environments. Traditional robotics rely on rigid designs that provide precision but require extensive safety measures such as barriers or sensors to protect users from accidental contact. Your choice between these technologies should consider the operational context, balancing the need for safety and performance.

Material Innovations in Soft Robotics

Material innovations in soft robotics, such as silicone elastomers, hydrogels, and shape-memory alloys, provide unmatched flexibility and adaptability compared to rigid components in traditional robotics. These materials enable soft robots to safely interact with humans and navigate complex environments by mimicking natural muscle movements. Your applications benefit from improved dexterity and resilience in sectors like healthcare, agriculture, and wearable technology due to these advanced material properties.

Performance and Precision Metrics

Soft robotics offers enhanced adaptability and safer interactions due to its flexible materials, making it ideal for delicate tasks requiring gentle manipulation. Traditional robotics excel in high precision and repeatability, with rigid structures enabling consistent performance in industrial automation and assembly lines. Performance metrics for soft robotics emphasize compliance and resilience, whereas traditional robotics prioritize accuracy, speed, and load capacity.

Application Areas and Industry Use Cases

Soft robotics excels in medical applications like minimally invasive surgery and prosthetics due to its flexibility and gentle interaction with human tissue. Traditional robotics dominates manufacturing and assembly lines, offering precision and strength for tasks such as welding, material handling, and packaging. Your choice between the two depends on the specific industry demands, with soft robotics favored in delicate environments and traditional robotics suited for heavy-duty, repetitive processes.

Current Challenges and Limitations

Soft robotics faces challenges in achieving precise control and durability compared to traditional robotics, which benefit from rigid structures and well-established control algorithms. Material limitations hinder soft robots' strength and longevity, restricting their use in heavy-duty or high-precision tasks where traditional robots excel. Integration of sensors and actuators in soft robotics remains complex, impeding real-time responsiveness and scalability found in conventional robotic systems.

Future Trends and Research Directions

Future trends in soft robotics emphasize developing bio-inspired materials and flexible actuators that enable safer human-robot interaction and adaptability in unstructured environments. Research directions prioritize improving sensory feedback, control algorithms, and energy efficiency to enhance soft robots' autonomy and functionality. Traditional robotics continues advancing in precision and computational power, but the integration of soft components is gaining momentum to bridge rigidity with flexibility for next-generation applications.

Soft Robotics vs Traditional Robotics Infographic

libmatt.com

libmatt.com