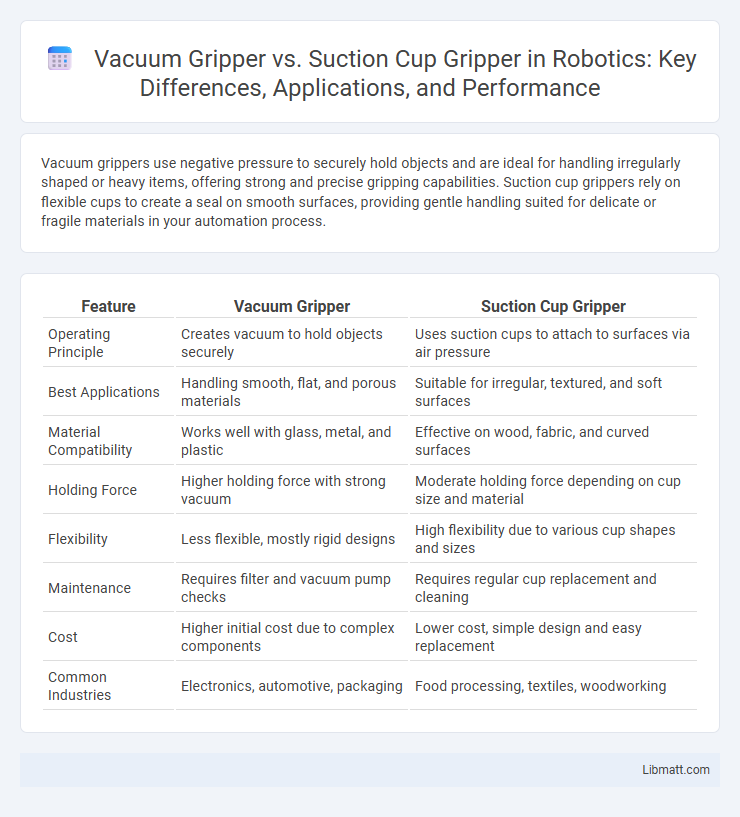

Vacuum grippers use negative pressure to securely hold objects and are ideal for handling irregularly shaped or heavy items, offering strong and precise gripping capabilities. Suction cup grippers rely on flexible cups to create a seal on smooth surfaces, providing gentle handling suited for delicate or fragile materials in your automation process.

Table of Comparison

| Feature | Vacuum Gripper | Suction Cup Gripper |

|---|---|---|

| Operating Principle | Creates vacuum to hold objects securely | Uses suction cups to attach to surfaces via air pressure |

| Best Applications | Handling smooth, flat, and porous materials | Suitable for irregular, textured, and soft surfaces |

| Material Compatibility | Works well with glass, metal, and plastic | Effective on wood, fabric, and curved surfaces |

| Holding Force | Higher holding force with strong vacuum | Moderate holding force depending on cup size and material |

| Flexibility | Less flexible, mostly rigid designs | High flexibility due to various cup shapes and sizes |

| Maintenance | Requires filter and vacuum pump checks | Requires regular cup replacement and cleaning |

| Cost | Higher initial cost due to complex components | Lower cost, simple design and easy replacement |

| Common Industries | Electronics, automotive, packaging | Food processing, textiles, woodworking |

Overview: Vacuum Gripper vs Suction Cup Gripper

Vacuum grippers use a vacuum system to create a strong, consistent hold on objects by removing air pressure, providing reliable performance for handling various materials and shapes. Suction cup grippers utilize flexible cups that adhere to surfaces through negative pressure, ideal for delicate or smooth objects requiring gentle handling. Your choice between vacuum and suction cup grippers depends on the application's demands for grip strength, object surface, and material compatibility.

Working Principles of Vacuum and Suction Cup Grippers

Vacuum grippers operate by creating a low-pressure zone through an integrated vacuum pump or ejector, gripping objects via atmospheric pressure, while suction cup grippers rely on flexible rubber cups to form a seal and generate suction through air evacuation. Both systems use negative pressure but differ in their mechanisms; vacuum grippers often maintain continuous suction with active pumps, whereas suction cup grippers depend on the physical elasticity of the cup to maintain grip. Your choice between these grippers depends on object shape, surface texture, and required holding force.

Key Components and Design Differences

Vacuum grippers utilize an integrated vacuum pump, sealed suction pads, and flexible connectors to create a controlled vacuum environment, while suction cup grippers rely on suction cups attached to a pneumatic or manual vacuum source for gripping. The design of vacuum grippers emphasizes compactness and automation compatibility, featuring multiple sealing elements and internal channels, whereas suction cup grippers prioritize simplicity and adaptability for varied surface types with interchangeable cup sizes. Understanding these key components and design differences helps you select the optimal solution for precise material handling and automation tasks.

Application Areas: Industry Use Cases

Vacuum grippers excel in heavy industrial applications such as automotive assembly and heavy machinery handling, where strong, reliable grip and high load capacity are crucial. Suction cup grippers are widely used in packaging, electronics, and food processing industries for delicate or irregularly shaped items requiring gentle handling and precision. Your choice will depend on the specific application needs including weight, surface texture, and material sensitivity to optimize performance and efficiency.

Performance Comparison: Holding Power and Efficiency

Vacuum grippers generally offer superior holding power due to their ability to maintain consistent negative pressure, making them highly efficient for handling heavy or irregularly shaped objects. Suction cup grippers provide reliable performance on smooth, non-porous surfaces but may struggle with porous or uneven materials, leading to lower holding strength and efficiency. The choice between the two depends on the specific application requirements, with vacuum grippers excelling in versatility and suction cups favored for simpler, lightweight tasks.

Material Compatibility and Versatility

Vacuum grippers excel in handling a wide range of materials, including porous and rough surfaces, due to their ability to maintain consistent suction through a vacuum system. Suction cup grippers perform best with smooth, non-porous materials, such as glass or polished metals, offering precise gripping but limited versatility on varied surfaces. Your choice depends on material compatibility and the specific application requirements for reliable and efficient handling.

Energy Consumption and Maintenance Requirements

Vacuum grippers typically consume more energy than suction cup grippers due to their need for continuous vacuum generation and air leakage compensation. Suction cup grippers require less maintenance because their simpler design has fewer moving parts and lower risk of wear or contamination. Efficient energy use and minimal upkeep make suction cup grippers preferable in applications demanding cost-effective and reliable performance.

Cost Analysis and Return on Investment

Vacuum grippers generally incur higher initial costs due to advanced technology and maintenance requirements compared to suction cup grippers, which are more affordable and easier to replace. Suction cup grippers offer faster deployment and lower energy consumption, contributing to a quicker return on investment in high-volume, light-duty applications. Complex industrial environments with varied surface conditions benefit from vacuum grippers' durability and precision, justifying their higher cost through improved productivity and reduced downtime.

Pros and Cons of Vacuum Grippers

Vacuum grippers offer precise handling of delicate and irregularly shaped objects with minimal surface damage, making them ideal for applications in electronics and glass industries. Their main advantages include high reliability, strong holding force, and adaptability to various materials without requiring complex mechanical components. However, vacuum grippers require a continuous power source for maintaining suction, may struggle with porous or rough surfaces, and can face limitations in handling very heavy items compared to mechanical grippers.

Pros and Cons of Suction Cup Grippers

Suction cup grippers offer excellent adaptability for handling smooth, flat, or slightly curved surfaces, making them ideal for delicate or irregular objects. They provide fast and gentle gripping with minimal risk of surface damage, but their effectiveness significantly decreases on porous, rough, or uneven materials. Your choice depends on the specific application requirements, as suction cup grippers may struggle in dusty or oily environments where vacuum grippers often provide more reliable performance.

Vacuum gripper vs Suction cup gripper Infographic

libmatt.com

libmatt.com