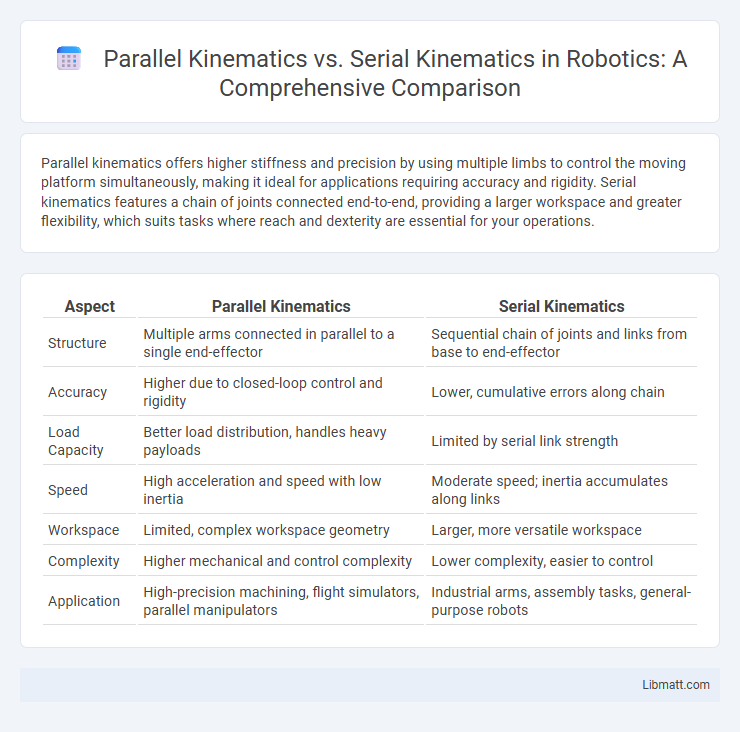

Parallel kinematics offers higher stiffness and precision by using multiple limbs to control the moving platform simultaneously, making it ideal for applications requiring accuracy and rigidity. Serial kinematics features a chain of joints connected end-to-end, providing a larger workspace and greater flexibility, which suits tasks where reach and dexterity are essential for your operations.

Table of Comparison

| Aspect | Parallel Kinematics | Serial Kinematics |

|---|---|---|

| Structure | Multiple arms connected in parallel to a single end-effector | Sequential chain of joints and links from base to end-effector |

| Accuracy | Higher due to closed-loop control and rigidity | Lower, cumulative errors along chain |

| Load Capacity | Better load distribution, handles heavy payloads | Limited by serial link strength |

| Speed | High acceleration and speed with low inertia | Moderate speed; inertia accumulates along links |

| Workspace | Limited, complex workspace geometry | Larger, more versatile workspace |

| Complexity | Higher mechanical and control complexity | Lower complexity, easier to control |

| Application | High-precision machining, flight simulators, parallel manipulators | Industrial arms, assembly tasks, general-purpose robots |

Introduction to Kinematic Structures

Parallel kinematic structures use multiple independent kinematic chains working simultaneously to control the end-effector, offering higher stiffness, accuracy, and load capacity compared to serial kinematic structures, which rely on a single chain of joints in series. Serial kinematics provide larger workspace and simpler control, making them suitable for applications requiring greater reach and flexibility. Understanding these fundamental differences helps you choose the right robotic system based on precision requirements and operational environment.

Defining Parallel Kinematics

Parallel kinematics involves multiple independent kinematic chains working simultaneously to control the motion of a single end-effector, enhancing rigidity and precision. Commonly found in Stewart platforms, parallel kinematic machines offer superior load distribution and reduced cumulative errors compared to serial kinematics. This configuration enables higher stiffness, improved dynamic response, and compact design, making it ideal for applications requiring high accuracy and stability.

Understanding Serial Kinematics

Serial kinematics involves a sequence of linked joints and links where each joint's movement depends on the previous one, forming a single chain from base to end-effector. This configuration provides a wide range of motion and simplicity in control but can suffer from lower stiffness and precision compared to parallel kinematics. Understanding serial kinematics helps you optimize robotic arm design for tasks requiring large workspace and dexterous manipulation.

Core Differences Between Parallel and Serial Kinematics

Parallel kinematics features multiple independent arms working simultaneously to control a single moving platform, offering higher stiffness, precision, and load capacity compared to serial kinematics, which consists of a chain of joints and links where each segment depends on the previous one. Serial kinematics allows for greater reach and flexibility but tends to accumulate errors and suffer from lower rigidity. Understanding these core differences helps you choose the appropriate mechanism based on the required accuracy, workspace size, and application demands.

Advantages of Parallel Kinematic Mechanisms

Parallel kinematic mechanisms offer superior stiffness and accuracy compared to serial kinematics due to their closed-loop structure distributing loads across multiple limbs. These systems provide higher payload capacity and faster dynamic response, making them ideal for precision machining and robotics applications. The compact design also reduces inertia, enhancing energy efficiency and minimizing positioning errors during complex movements.

Benefits of Serial Kinematic Systems

Serial kinematic systems offer greater workspace flexibility and simpler control algorithms compared to parallel kinematics, making them ideal for applications requiring extensive reach and complex motion paths. They provide easier calibration and maintenance due to their straightforward joint arrangement, which reduces downtime and operational costs. The modular design of serial robots allows for scalable customization and better adaptability in diverse industrial environments.

Limitations and Challenges of Parallel Kinematics

Parallel kinematics mechanisms face limitations such as reduced workspace size and increased complexity in control systems compared to serial kinematics. Their structural rigidity can lead to higher manufacturing costs and difficulties in achieving precise calibration and maintenance. Challenges include managing complex singularities and ensuring accurate motion synchronization of multiple actuators for stable operation.

Limitations and Challenges of Serial Kinematics

Serial kinematics systems face limitations such as reduced stiffness and lower load-carrying capacity compared to parallel kinematics, making them less suitable for high-precision tasks under heavy loads. Their cumulative joint errors lead to decreased accuracy and repeatability, impacting overall performance in complex manipulations. You must address these challenges when choosing serial kinematics for applications requiring high rigidity and precision.

Applications in Robotics and Automation

Parallel kinematics mechanisms are widely used in robotics and automation for tasks requiring high precision and stiffness, such as CNC machining, flight simulators, and robotic surgery, due to their ability to distribute loads across multiple limbs. Serial kinematics robots are commonly applied in assembly lines, packaging, and material handling because of their larger workspaces and greater flexibility in movement. The selection between parallel and serial kinematics depends on factors like payload capacity, accuracy, workspace size, and complexity of motion required in industrial automation systems.

Future Trends: Parallel vs Serial Kinematic Development

Future trends in kinematic development emphasize enhanced precision and speed through parallel kinematics, ideal for applications requiring high stiffness and dynamic load capacity. Serial kinematics continue evolving with advancements in modularity and adaptability, making them suitable for complex, multi-degree-of-freedom tasks requiring extensive reach and flexibility. Your choice between parallel and serial kinematics will depend on the specific performance requirements and operational environment of the robotic system.

Parallel Kinematics vs Serial Kinematics Infographic

libmatt.com

libmatt.com