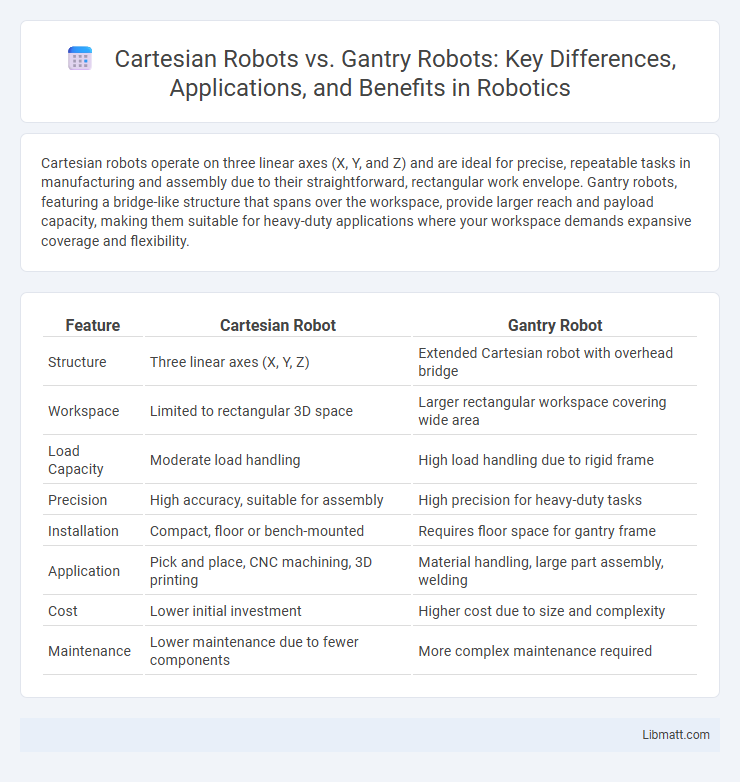

Cartesian robots operate on three linear axes (X, Y, and Z) and are ideal for precise, repeatable tasks in manufacturing and assembly due to their straightforward, rectangular work envelope. Gantry robots, featuring a bridge-like structure that spans over the workspace, provide larger reach and payload capacity, making them suitable for heavy-duty applications where your workspace demands expansive coverage and flexibility.

Table of Comparison

| Feature | Cartesian Robot | Gantry Robot |

|---|---|---|

| Structure | Three linear axes (X, Y, Z) | Extended Cartesian robot with overhead bridge |

| Workspace | Limited to rectangular 3D space | Larger rectangular workspace covering wide area |

| Load Capacity | Moderate load handling | High load handling due to rigid frame |

| Precision | High accuracy, suitable for assembly | High precision for heavy-duty tasks |

| Installation | Compact, floor or bench-mounted | Requires floor space for gantry frame |

| Application | Pick and place, CNC machining, 3D printing | Material handling, large part assembly, welding |

| Cost | Lower initial investment | Higher cost due to size and complexity |

| Maintenance | Lower maintenance due to fewer components | More complex maintenance required |

Introduction to Cartesian and Gantry Robots

Cartesian robots operate on three linear axes (X, Y, Z) within a rectangular coordinate system, providing precise, repeatable motion ideal for applications such as CNC machining and 3D printing. Gantry robots are a type of Cartesian robot featuring a framework that spans a large work area, often used in heavy-duty tasks like automated heavy part assembly or large-scale material handling. Both systems rely on linear actuators, but gantry robots offer enhanced rigidity and scalability for industrial automation.

Overview of Cartesian Robot Systems

Cartesian robot systems utilize three linear axes (X, Y, and Z) arranged orthogonally, enabling precise and repeatable movement within a defined rectangular workspace. These robots excel in applications requiring high rigidity, accuracy, and straightforward programming, commonly found in CNC machining, 3D printing, and pick-and-place tasks. The simplicity of their design allows for easy scalability and integration into automated manufacturing processes, making them cost-effective solutions for linear motion requirements.

What is a Gantry Robot?

A Gantry Robot, also known as a Cartesian robot, operates on three linear axes (X, Y, and Z) to perform precise and repeatable movements within a defined rectangular work envelope. Its rigid frame and overhead structure allow high load capacities and stability, making it ideal for applications like assembly, pick-and-place, machining, and 3D printing. The Cartesian coordinate system simplifies programming and integration with automated processes in industries such as aerospace, automotive, and electronics manufacturing.

Key Design Differences: Cartesian vs Gantry Robots

Cartesian robots operate on three linear axes arranged orthogonally (X, Y, and Z), providing precise, controlled movements within a rectangular work envelope. Gantry robots, a subset of Cartesian robots, feature a sturdy bridge-like frame spanning the workspace, enabling support for heavy loads and larger working areas with enhanced rigidity. The primary design difference lies in the gantry's overhead structure, which distributes weight more effectively, whereas standard Cartesian robots rely on linear slides without the extended frame.

Working Principles and Motion Control

Cartesian robots operate on three linear axes--X, Y, and Z--moving in straight lines with precise position control based on a rectangular coordinate system. Gantry robots also move along three perpendicular linear axes but feature a larger, bridge-like frame that spans the workspace, enabling enhanced load capacity and stability. Motion control in Cartesian robots is typically managed through linear actuators and stepper or servo motors, while gantry robots often utilize synchronized motor drives and advanced feedback systems to coordinate complex, scalable movements.

Applications of Cartesian Robots

Cartesian robots excel in applications requiring precise linear movements, such as CNC machining, 3D printing, and automated assembly lines. Their design allows for straightforward programming and scalability, making them ideal for pick-and-place tasks in electronics manufacturing and packaging industries. Using a Cartesian robot can enhance your production efficiency through high accuracy and repeatability in controlled environments.

Use Cases for Gantry Robots

Gantry robots excel in large-scale, high-precision applications such as automotive assembly lines, where extensive reach and rigidity are crucial for weighty parts. They are ideal for pick-and-place operations, material handling, and packaging in manufacturing environments requiring repeatable accuracy and load capacities beyond typical robotic arms. Your choice of a gantry robot enhances automation efficiency in industries needing scalable, multi-axis movement across substantial workspaces.

Comparative Advantages and Limitations

Cartesian robots excel in applications requiring high precision and rigidity due to their linear axes, making them ideal for tasks like CNC machining and 3D printing. Gantry robots offer greater reach and versatility with multi-axis movement, enabling complex assembly and material handling over large areas, but they can be more costly and require extensive setup space. Your choice depends on balancing precision needs against workspace size and application complexity.

Cost and Integration Considerations

Cartesian robots typically offer lower upfront costs due to their simpler design and ease of customization for linear movement tasks, making them suitable for budget-conscious automation projects. Gantry robots generally involve higher initial investment but provide superior scalability and integration flexibility for large-scale manufacturing environments. Integration of Cartesian systems is straightforward with standard control interfaces, whereas gantry robots require more advanced programming and infrastructure adjustments to optimize performance in complex workflows.

Choosing Between Cartesian and Gantry Robots

Choosing between Cartesian and gantry robots depends on the application's precision, workspace, and payload requirements. Cartesian robots offer high accuracy and repeatability within a rectangular workspace, making them ideal for tasks like assembly and CNC machining. Gantry robots provide larger working areas and greater load capacity, suited for heavy-duty material handling and large-scale automation.

Cartesian vs Gantry Robot Infographic

libmatt.com

libmatt.com