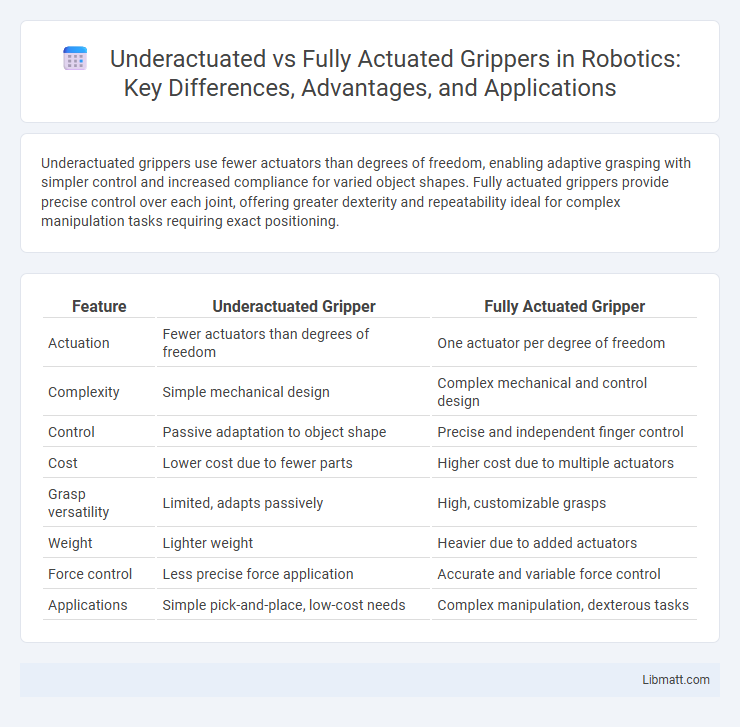

Underactuated grippers use fewer actuators than degrees of freedom, enabling adaptive grasping with simpler control and increased compliance for varied object shapes. Fully actuated grippers provide precise control over each joint, offering greater dexterity and repeatability ideal for complex manipulation tasks requiring exact positioning.

Table of Comparison

| Feature | Underactuated Gripper | Fully Actuated Gripper |

|---|---|---|

| Actuation | Fewer actuators than degrees of freedom | One actuator per degree of freedom |

| Complexity | Simple mechanical design | Complex mechanical and control design |

| Control | Passive adaptation to object shape | Precise and independent finger control |

| Cost | Lower cost due to fewer parts | Higher cost due to multiple actuators |

| Grasp versatility | Limited, adapts passively | High, customizable grasps |

| Weight | Lighter weight | Heavier due to added actuators |

| Force control | Less precise force application | Accurate and variable force control |

| Applications | Simple pick-and-place, low-cost needs | Complex manipulation, dexterous tasks |

Introduction to Robotic Grippers

Underactuated grippers utilize fewer actuators than degrees of freedom, enabling adaptive, compliant grasping with simplified control, ideal for handling irregular objects efficiently. Fully actuated grippers feature individual actuators for each joint, offering precise, independent control for complex manipulation tasks requiring dexterity and repeatability. Your choice between underactuated and fully actuated grippers depends on the balance between task complexity, control requirements, and cost constraints in robotic applications.

What Are Underactuated Grippers?

Underactuated grippers utilize fewer actuators than the degrees of freedom in their mechanisms, enabling adaptive grasping through passive mechanical compliance. These grippers rely on the natural interaction between the object and the fingers to achieve secure, robust grasps without the need for precise control of each joint. This design simplifies hardware, reduces cost and weight, and enhances versatility in handling diverse object shapes compared to fully actuated grippers that require independent control of all joints.

What Are Fully Actuated Grippers?

Fully actuated grippers feature individual actuators for each degree of freedom, providing precise and independent control of every finger or joint. This design enables complex manipulation tasks, high adaptability to varied object shapes, and enhanced grip stability. These grippers are commonly used in industrial robotics where precision and dexterity are critical.

Key Differences: Underactuated vs Fully Actuated

Underactuated grippers feature fewer actuators than degrees of freedom, relying on passive elements like springs or flexible joints to adapt to object shapes, which enhances robustness and simplifies control but limits precise manipulation. Fully actuated grippers provide independent control of each joint or finger through dedicated actuators, offering superior dexterity and accuracy at the cost of increased mechanical complexity and control demands. The key difference lies in the trade-off between adaptability and control complexity, where underactuated grippers excel in handling diverse, irregular objects with minimal control input, while fully actuated grippers enable precise, versatile manipulation in structured tasks.

Mechanical Design and Complexity

Underactuated grippers feature fewer actuators than degrees of freedom, utilizing compliant mechanisms and passive adaptability to conform to object shapes, resulting in simpler mechanical designs and reduced control complexity. Fully actuated grippers possess dedicated actuators for each joint or finger, enabling precise control at the cost of increased mechanical complexity and higher system weight. The simplified architecture of underactuated grippers offers advantages in terms of robustness and cost-effectiveness, whereas fully actuated designs provide superior dexterity and manipulation accuracy.

Control Strategies and Precision

Underactuated grippers utilize fewer actuators than degrees of freedom, relying on adaptive mechanisms and passive compliance for object grasping, which simplifies control strategies but can limit precision in complex tasks. Fully actuated grippers employ individual actuators for each degree of freedom, enabling precise control over finger positions and forces, resulting in higher accuracy and repeatability. Control algorithms for fully actuated systems often incorporate advanced feedback loops and real-time adjustments to maximize manipulation precision.

Adaptability to Various Objects

Underactuated grippers use fewer actuators than degrees of freedom, allowing passive adaptability and self-adjustment to diverse object shapes and sizes through compliant mechanisms. Fully actuated grippers have independent control over each joint, providing precise manipulation but limited natural adaptability without complex control algorithms. This makes underactuated designs more efficient for handling irregular and unknown objects in unstructured environments.

Cost and Maintenance Considerations

Underactuated grippers typically have fewer actuators and simpler mechanical designs, leading to lower manufacturing costs and reduced maintenance requirements compared to fully actuated grippers. Fully actuated grippers feature individual actuators for each degree of freedom, increasing complexity, initial investment, and potential maintenance challenges. Cost-effectiveness and ease of upkeep make underactuated grippers preferable for applications prioritizing budget and minimal downtime.

Application Scenarios and Use Cases

Underactuated grippers excel in applications requiring adaptability and simple, cost-effective handling of irregular or delicate objects, such as in packaging, agriculture, and prosthetics where compliance and energy efficiency are crucial. Fully actuated grippers are preferred in precision-driven tasks like assembly lines, robotic surgery, and high-precision manufacturing, offering independent finger control for complex manipulation and enhanced dexterity. The choice between underactuated and fully actuated grippers depends on the trade-off between adaptability with fewer control inputs and the need for precise, customizable finger movements in specific industrial or medical environments.

Choosing the Right Gripper for Your Needs

Underactuated grippers offer adaptive gripping with fewer actuators, making them lighter and more cost-effective for handling objects with varying shapes and sizes. Fully actuated grippers provide precise control over each finger or joint, ideal for tasks requiring high dexterity and consistent force. Choosing the right gripper depends on your application's complexity, budget, and need for adaptability or precise manipulation.

Underactuated gripper vs Fully actuated gripper Infographic

libmatt.com

libmatt.com