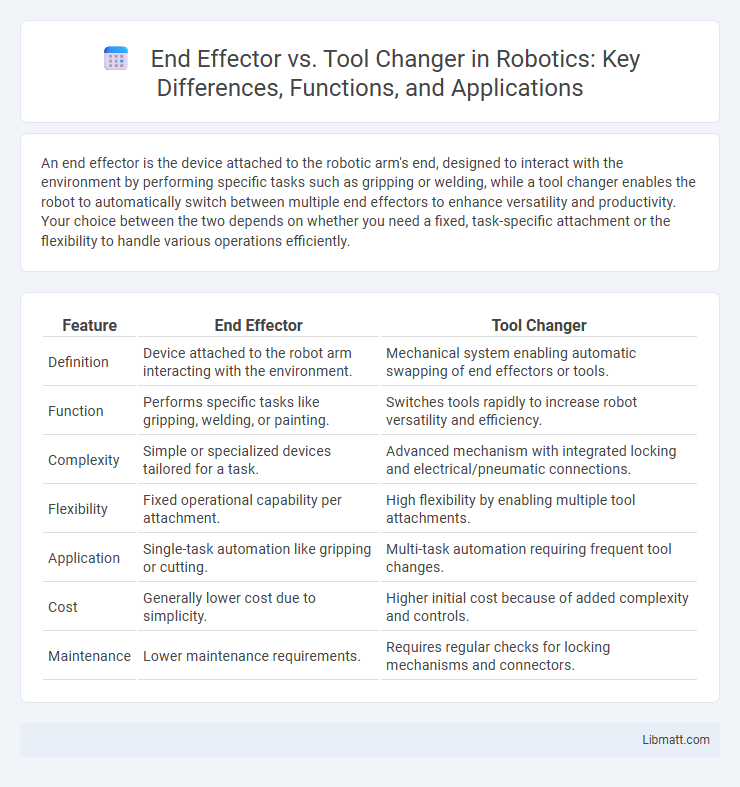

An end effector is the device attached to the robotic arm's end, designed to interact with the environment by performing specific tasks such as gripping or welding, while a tool changer enables the robot to automatically switch between multiple end effectors to enhance versatility and productivity. Your choice between the two depends on whether you need a fixed, task-specific attachment or the flexibility to handle various operations efficiently.

Table of Comparison

| Feature | End Effector | Tool Changer |

|---|---|---|

| Definition | Device attached to the robot arm interacting with the environment. | Mechanical system enabling automatic swapping of end effectors or tools. |

| Function | Performs specific tasks like gripping, welding, or painting. | Switches tools rapidly to increase robot versatility and efficiency. |

| Complexity | Simple or specialized devices tailored for a task. | Advanced mechanism with integrated locking and electrical/pneumatic connections. |

| Flexibility | Fixed operational capability per attachment. | High flexibility by enabling multiple tool attachments. |

| Application | Single-task automation like gripping or cutting. | Multi-task automation requiring frequent tool changes. |

| Cost | Generally lower cost due to simplicity. | Higher initial cost because of added complexity and controls. |

| Maintenance | Lower maintenance requirements. | Requires regular checks for locking mechanisms and connectors. |

Introduction to End Effectors and Tool Changers

End effectors are devices attached to robotic arms that interact directly with the environment, designed for specific tasks such as gripping, welding, or painting. Tool changers are mechanical systems that enable robots to switch between multiple end effectors automatically, enhancing versatility and reducing downtime in automated processes. Both components are crucial in industrial automation, enabling efficient task execution and flexible production lines.

Defining End Effectors: Purpose and Types

End effectors are critical components of robotic arms designed to interact with the environment by performing specific tasks such as gripping, welding, or painting. They come in various types including grippers, suction cups, welding torches, and sensors, each tailored for precise industrial applications. The purpose of an end effector is to convert the robotic arm's motion into functional work, enhancing automation efficiency and versatility.

Understanding Tool Changers: Functionality and Applications

Tool changers automate the process of switching end effectors on robotic arms, enhancing operational efficiency by enabling seamless transitions between different tools without manual intervention. These devices are crucial in manufacturing and assembly lines where multiple tasks require varied end effectors, such as grippers, welders, or sensors. Understanding your system's tool changer capabilities ensures optimal integration and maximizes productivity in complex automation workflows.

Key Differences Between End Effectors and Tool Changers

End effectors are devices attached to the robotic arm's flange designed to interact directly with objects, such as grippers, welders, or suction cups, while tool changers enable robots to switch between multiple end effectors automatically, enhancing versatility and efficiency. Key differences include the function where end effectors perform the primary task on the workpiece, whereas tool changers facilitate rapid swapping of these end effectors without manual intervention. Tool changers are essential in environments requiring multiple tooling operations, reducing downtime and increasing robotic system flexibility compared to fixed end effectors.

Advantages of Using End Effectors in Automation

End effectors enhance automation by providing precise control and adaptability to various tasks such as gripping, welding, or painting, improving operational efficiency. They offer quick tool changes without the complexity of a tool changer system, reducing downtime and maintenance costs. Your automation processes benefit from increased flexibility and reliability when integrating specialized end effectors tailored to specific applications.

Benefits of Integrating Tool Changers in Robotics

Integrating tool changers in robotics enhances operational flexibility by allowing seamless switching between multiple end effectors, increasing productivity in automated workflows. This capability reduces downtime and manual intervention, optimizing your robotic systems for diverse manufacturing tasks. Tool changers expand the robot's versatility, enabling efficient handling of complex processes and improving overall automation efficiency.

Choosing Between End Effectors and Tool Changers

Choosing between end effectors and tool changers depends on your robotic application's flexibility and precision requirements. End effectors provide specialized, fixed-function tools such as grippers or welders, ideal for tasks needing consistent performance. Tool changers offer quick swapping of multiple tools without manual intervention, enhancing productivity in complex or multi-step processes.

Compatibility and Integration Considerations

End effectors require precise compatibility with a robot's wrist flange, including matching mechanical fit, electrical connections, and communication protocols for seamless integration. Tool changers must support multiple end effectors, ensuring quick and secure switching while maintaining alignment, power, and signal integrity across diverse tools. Integration considerations also include software support for automated tool recognition and system calibration to optimize performance and reduce downtime.

Industry Applications: End Effector vs Tool Changer

End effectors are widely used in industries requiring precise handling, such as electronics assembly and medical device manufacturing, where specific tasks like gripping, welding, or painting need tailor-made solutions. Tool changers excel in automotive and aerospace sectors, enabling robots to switch between multiple tools quickly for drilling, milling, and fastening operations, enhancing production flexibility and efficiency. Your choice between an end effector and a tool changer depends on the complexity and variety of tasks, with end effectors offering task-specific precision and tool changers providing versatile multi-tool functionality.

Future Trends in End Effectors and Tool Changers

Future trends in end effectors and tool changers emphasize enhanced automation and smart integration with Industry 4.0 technologies, enabling greater precision and flexibility in manufacturing processes. Advanced sensors and AI-driven control systems improve adaptability, allowing your robotic arms to switch tools seamlessly and perform complex tasks without human intervention. Innovations in lightweight, modular designs also contribute to increased efficiency and reduced downtime in automated production lines.

End Effector vs Tool Changer Infographic

libmatt.com

libmatt.com