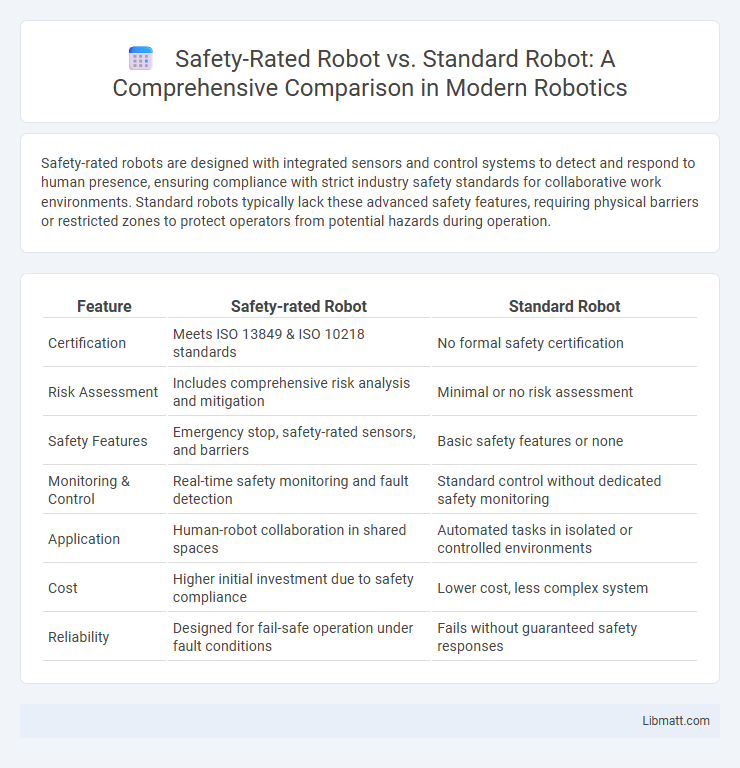

Safety-rated robots are designed with integrated sensors and control systems to detect and respond to human presence, ensuring compliance with strict industry safety standards for collaborative work environments. Standard robots typically lack these advanced safety features, requiring physical barriers or restricted zones to protect operators from potential hazards during operation.

Table of Comparison

| Feature | Safety-rated Robot | Standard Robot |

|---|---|---|

| Certification | Meets ISO 13849 & ISO 10218 standards | No formal safety certification |

| Risk Assessment | Includes comprehensive risk analysis and mitigation | Minimal or no risk assessment |

| Safety Features | Emergency stop, safety-rated sensors, and barriers | Basic safety features or none |

| Monitoring & Control | Real-time safety monitoring and fault detection | Standard control without dedicated safety monitoring |

| Application | Human-robot collaboration in shared spaces | Automated tasks in isolated or controlled environments |

| Cost | Higher initial investment due to safety compliance | Lower cost, less complex system |

| Reliability | Designed for fail-safe operation under fault conditions | Fails without guaranteed safety responses |

Understanding Safety-Rated Robots

Safety-rated robots comply with international standards such as ISO 10218 and ISO/TS 15066, ensuring they have built-in features to protect human operators during interaction. These robots use advanced sensors, speed monitoring, and force limitations to detect and respond to potential hazards, minimizing the risk of injury. Understanding the differences helps you select the right robot for environments where human safety is paramount, compared to standard robots that lack these specialized safety measures.

What Defines a Standard Robot?

A standard robot operates without integrated safety features designed to prevent accidents or injuries, relying instead on external safety systems and controlled environments for risk management. It typically functions at higher speeds and forces, suitable for isolated work cells to minimize human interaction. Standard robots lack compliance with strict safety standards such as ISO 10218 or ISO/TS 15066, distinguishing them from safety-rated robots engineered for collaborative tasks and enhanced hazard detection.

Key Differences Between Safety-Rated and Standard Robots

Safety-rated robots feature integrated sensors and control systems designed to detect and respond to hazardous conditions, ensuring compliance with strict safety standards like ISO 13849. Standard robots lack these advanced safety functions, posing higher risks in collaborative environments or tasks involving human interaction. Understanding these key differences allows you to select the appropriate robot that prioritizes safety without compromising on performance.

Safety Certifications and Standards in Robotics

Safety-rated robots comply with rigorous safety certifications such as ISO 10218 and ISO/TS 15066, ensuring reliable protection for human operators in industrial environments. Standard robots may lack these certifications, focusing primarily on performance rather than integrated safety functions. Compliance with standards like ANSI/RIA R15.06 enhances risk assessment and hazard mitigation for safety-rated robots, promoting safer human-robot collaboration.

Work Environment Suitability: Which Robot Fits Where?

Safety-rated robots are designed to operate in dynamic environments where human workers are present, incorporating sensors and safety features that allow for real-time detection and response to prevent accidents. Standard robots are more suitable for restricted or isolated areas, such as caged zones or industrial cells, where human interaction is minimal or controlled. Choosing between safety-rated and standard robots depends on the specific work environment requirements, regulatory compliance, and the level of human-robot interaction anticipated.

Risk Assessment: Protecting Humans in Automated Spaces

Safety-rated robots integrate advanced sensors and real-time monitoring systems to perform continuous risk assessments, minimizing hazards in automated environments. These robots comply with international safety standards such as ISO 10218 and ISO/TS 15066, ensuring reliable human-robot interaction and preventing accidents. Standard robots lack these dynamic safety features, increasing the potential for workplace injuries in collaborative settings.

Integration Challenges with Safety-Rated Robots

Integrating safety-rated robots requires strict compliance with international safety standards such as ISO 13849 and ISO 10218, often necessitating specialized control systems and safety-rated sensors. These robots demand rigorous validation and certification processes to ensure fail-safe operations, which can extend deployment timelines compared to standard robots. Your engineering team must address these challenges by enhancing system reliability and ensuring seamless communication between safety functions and core automation processes.

Cost Comparison: Safety Investment vs. Budget Constraints

Safety-rated robots typically involve higher upfront costs due to advanced sensors, certifications, and compliance with stringent safety standards, reflecting a significant safety investment. Standard robots, while more affordable initially, may incur additional expenses related to workplace modifications and increased risk management protocols. Your budget constraints should weigh the long-term benefits of risk reduction and potential liability costs against the initial expense of integrating safety-rated technology.

Productivity and Performance: Does Safety Impact Output?

Safety-rated robots integrate advanced sensors and real-time monitoring systems that enable seamless human-robot collaboration without extensive safety barriers, enhancing productivity by reducing downtime and workspace limitations. Standard robots often require physical safety fencing and slower operational speeds to prevent accidents, which can limit performance and output capacity. Your production line benefits from safety-rated robots through increased throughput and operational efficiency without compromising workplace safety standards.

Future Trends: The Rise of Safety-Rated Robotics

Safety-rated robots are increasingly integrated with advanced sensors, AI-driven decision-making, and real-time monitoring systems to enhance workplace safety and comply with stringent industrial standards like ISO 13849 and IEC 62061. The rise of collaborative robots (cobots) emphasizes safety-rated features, allowing humans and machines to work side-by-side without physical barriers, boosting productivity in smart factories. Future trends point to expanded adoption across sectors such as automotive, electronics, and logistics, driven by enhanced risk assessment algorithms and regulatory pressure to minimize workplace incidents.

Safety-rated Robot vs Standard Robot Infographic

libmatt.com

libmatt.com