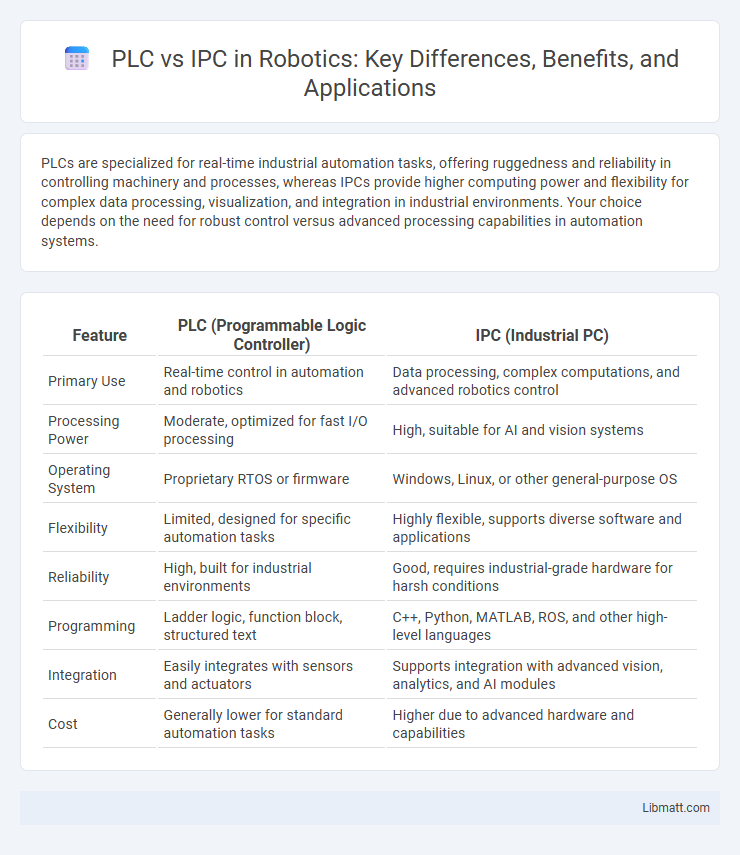

PLCs are specialized for real-time industrial automation tasks, offering ruggedness and reliability in controlling machinery and processes, whereas IPCs provide higher computing power and flexibility for complex data processing, visualization, and integration in industrial environments. Your choice depends on the need for robust control versus advanced processing capabilities in automation systems.

Table of Comparison

| Feature | PLC (Programmable Logic Controller) | IPC (Industrial PC) |

|---|---|---|

| Primary Use | Real-time control in automation and robotics | Data processing, complex computations, and advanced robotics control |

| Processing Power | Moderate, optimized for fast I/O processing | High, suitable for AI and vision systems |

| Operating System | Proprietary RTOS or firmware | Windows, Linux, or other general-purpose OS |

| Flexibility | Limited, designed for specific automation tasks | Highly flexible, supports diverse software and applications |

| Reliability | High, built for industrial environments | Good, requires industrial-grade hardware for harsh conditions |

| Programming | Ladder logic, function block, structured text | C++, Python, MATLAB, ROS, and other high-level languages |

| Integration | Easily integrates with sensors and actuators | Supports integration with advanced vision, analytics, and AI modules |

| Cost | Generally lower for standard automation tasks | Higher due to advanced hardware and capabilities |

Introduction to PLCs and IPCs

PLCs (Programmable Logic Controllers) are specialized industrial computers designed for real-time control and automation of machinery and processes in manufacturing environments. IPCs (Industrial PCs) offer versatile computing power with robust hardware tailored for industrial applications, enabling complex data processing and integration with automation systems. Both PLCs and IPCs play critical roles in modern industrial automation, with PLCs excelling in control tasks and IPCs providing advanced computational capabilities.

Core Functions and Architectures

PLCs (Programmable Logic Controllers) feature modular, real-time control architectures designed primarily for discrete automation tasks, enabling reliable I/O processing and ladder logic execution. IPCs (Industrial PCs) offer flexible, high-performance computing architectures with multitasking operating systems suitable for complex data analysis, HMI, and advanced control algorithms. Your automation choice depends on whether you prioritize deterministic control with PLCs or versatile computing power with IPCs.

Performance Comparison: Speed and Reliability

PLCs (Programmable Logic Controllers) excel in real-time processing with cycle times typically under 1 ms, ensuring high-speed and deterministic control for industrial automation tasks. IPCs (Industrial PCs), while offering greater computational power and flexibility, often experience longer response times due to operating system overheads, impacting real-time performance. In terms of reliability, PLCs are designed for harsh industrial environments with robust hardware and fail-safe features, whereas IPCs require additional ruggedization to achieve comparable durability.

Scalability and Flexibility in Industrial Applications

PLCs (Programmable Logic Controllers) offer high reliability and real-time control with fixed hardware configurations, making them ideal for predictable, repetitive tasks but limited in scalability. IPCs (Industrial PCs) provide superior scalability and flexibility due to modular hardware, software customization, and higher processing power, enabling complex data analysis and integration with IT systems. In industrial applications requiring adaptability and expansion, IPCs support evolving production needs better than traditional PLCs.

Ease of Programming and User Interface

PLCs feature logic-based programming languages such as Ladder Logic, making them accessible for users with electrical and control backgrounds. IPCs offer more advanced programming options, including high-level languages like Python or C++, catering to complex data processing and customization needs. Your choice depends on whether you prioritize straightforward programming ease or require sophisticated user interface capabilities.

Integration with Industrial Networks

PLCs offer robust integration with traditional industrial networks such as PROFIBUS, Modbus, and Ethernet/IP, enabling reliable communication in automation systems. IPCs support a broader range of network protocols including OPC UA, Ethernet/IP, and MQTT, facilitating seamless connectivity with modern Industrial Internet of Things (IIoT) platforms. Your choice depends on whether you prioritize established network compatibility (PLC) or advanced, flexible integration capabilities (IPC).

Cost Analysis and Maintenance Considerations

PLCs (Programmable Logic Controllers) generally offer lower initial costs and simpler maintenance due to standardized components and widespread industry support, making them ideal for basic automation tasks. IPCs (Industrial PCs), while having higher upfront expenses owing to advanced hardware and software capabilities, provide greater flexibility and scalability but require specialized technical expertise for maintenance. Evaluating long-term operational costs, including system upgrades and downtime, is crucial when choosing between PLCs and IPCs for industrial automation projects.

Security and System Updates

PLCs often have limited security features and rely on manufacturer updates, which can be infrequent, making them more vulnerable to cyber threats. IPCs support robust operating systems and can receive regular security patches and system updates, enhancing protection against evolving cyberattacks. To maintain optimal security, you should ensure your system's firmware and software are consistently updated, especially when using PLCs that may lack automatic patch management.

Typical Use Cases and Industry Adoption

PLCs excel in real-time control for manufacturing automation, assembly lines, and process industries due to their rugged design and fast I/O response. IPCs find extensive use in complex data processing, machine vision, and human-machine interface applications within automotive, semiconductor, and electronics manufacturing sectors. Your choice depends on whether the priority is deterministic control and reliability (PLC) or computing power and flexibility (IPC) to meet specific industrial requirements.

Future Trends: PLCs vs IPCs in Industry 4.0

PLCs (Programmable Logic Controllers) continue to excel in deterministic control and real-time automation, crucial for Industry 4.0's smart manufacturing environments. IPCs (Industrial PCs) offer advanced processing power, data analytics, and integration capabilities, enabling edge computing and AI-driven decision-making in industrial operations. Future trends indicate a hybrid approach leveraging PLCs' reliability and IPCs' computational strength to achieve seamless Industry 4.0 connectivity and enhanced operational efficiency.

PLC vs IPC Infographic

libmatt.com

libmatt.com