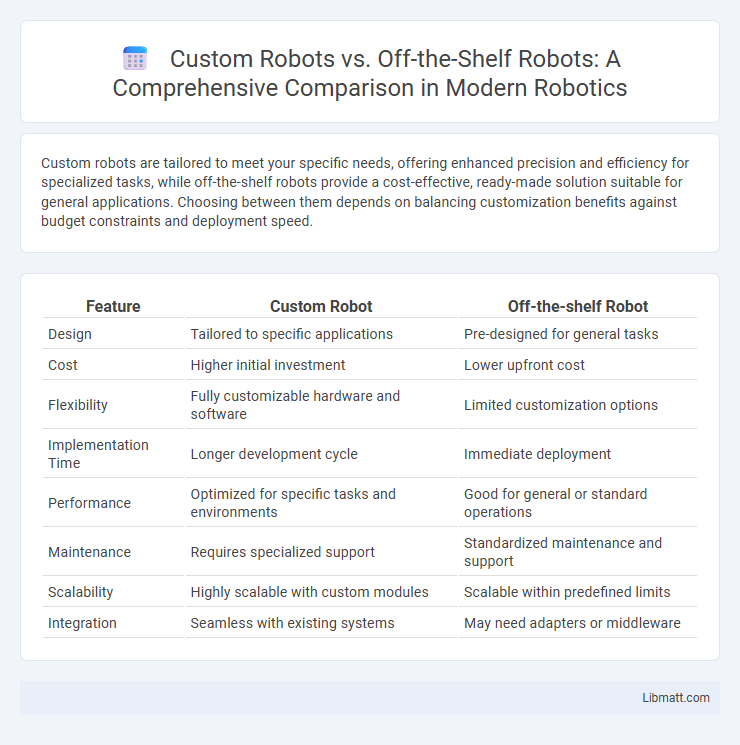

Custom robots are tailored to meet your specific needs, offering enhanced precision and efficiency for specialized tasks, while off-the-shelf robots provide a cost-effective, ready-made solution suitable for general applications. Choosing between them depends on balancing customization benefits against budget constraints and deployment speed.

Table of Comparison

| Feature | Custom Robot | Off-the-shelf Robot |

|---|---|---|

| Design | Tailored to specific applications | Pre-designed for general tasks |

| Cost | Higher initial investment | Lower upfront cost |

| Flexibility | Fully customizable hardware and software | Limited customization options |

| Implementation Time | Longer development cycle | Immediate deployment |

| Performance | Optimized for specific tasks and environments | Good for general or standard operations |

| Maintenance | Requires specialized support | Standardized maintenance and support |

| Scalability | Highly scalable with custom modules | Scalable within predefined limits |

| Integration | Seamless with existing systems | May need adapters or middleware |

Introduction: Defining Custom and Off-the-shelf Robots

Custom robots are designed and built to meet specific operational requirements, allowing tailored functionality, integration, and adaptability for unique industrial or commercial applications. Off-the-shelf robots are mass-produced, standardized solutions readily available for general purposes, offering quicker deployment and cost-effectiveness but limited flexibility. Understanding the distinctions between custom and off-the-shelf robots is crucial for selecting the appropriate automation technology based on project complexity, budget, and scalability needs.

Cost Comparison: Upfront Investment and Long-term Value

Custom robots typically require a higher upfront investment due to tailored design, engineering, and integration costs, but they offer enhanced long-term value through optimized performance, scalability, and adaptability to specific tasks. Off-the-shelf robots have lower initial costs and faster deployment times, making them attractive for general applications with predictable workflows. Over time, custom robots can reduce operational expenses by minimizing downtime and increasing efficiency, while off-the-shelf solutions may incur additional costs for modifications or limited flexibility.

Flexibility and Adaptability in Robot Design

Custom robots offer superior flexibility and adaptability in robot design by allowing precise tailoring to specific tasks and environments, enhancing operational efficiency. Off-the-shelf robots generally provide standardized functionality with limited customization, suitable for repetitive or broad applications but less effective for unique or evolving needs. Integrating modular components in custom robots further improves scalability and adaptability to future technological advancements.

Integration with Existing Systems

Custom robots offer seamless integration with your existing systems by being tailored to specific workflows, ensuring compatibility with current software and hardware. Off-the-shelf robots may require additional customization or middleware to fit into established processes, potentially leading to delays or higher costs. Choosing a custom robot enhances operational efficiency through bespoke system alignment.

Time to Deployment: Speed vs. Customization

Custom robots typically require longer development time due to tailored specifications and complex design processes, resulting in extended time to deployment compared to off-the-shelf robots. Off-the-shelf robots offer rapid implementation with pre-designed features and standardized components, enabling quicker integration into existing systems. Choosing between speed and customization depends on specific operational needs, with off-the-shelf solutions excelling in swift deployment and custom robots providing precise functionality for specialized tasks.

Maintenance, Support, and Upgrade Considerations

Custom robots offer tailored maintenance plans and dedicated support teams, ensuring your system remains optimized and adaptable to unique operational needs. Off-the-shelf robots typically provide standardized support and upgrades, which may lead to longer downtimes if specific issues arise outside common use cases. Choosing between them impacts the ease of future upgrades and the level of personalized assistance available to maintain peak performance.

Performance Optimization for Specific Tasks

Custom robots offer superior performance optimization for specific tasks by being tailored to your exact operational requirements, ensuring maximum efficiency and precision. Off-the-shelf robots provide general-purpose functionality but often lack the fine-tuned capabilities necessary for specialized applications. Investing in a custom robot results in enhanced productivity and reduced downtime for task-specific workflows.

Scalability: Meeting Evolving Business Needs

Custom robots offer superior scalability by allowing businesses to tailor features and functionalities to specific growth demands, ensuring seamless integration with evolving workflows. Off-the-shelf robots provide quick deployment but often lack the flexibility to adapt to complex or changing operational requirements. Investing in a custom robotic solution enables long-term scalability that aligns precisely with the trajectory of business expansion and innovation.

Intellectual Property and Competitive Advantage

Custom robots provide companies with exclusive intellectual property rights, enabling unique designs and functionalities that create strong competitive advantages in niche markets. Off-the-shelf robots, while cost-effective and quicker to deploy, often lack differentiation, making it harder to protect innovations through patents or trade secrets. Investing in custom robotics enhances proprietary technology ownership, fostering long-term market leadership and reducing the risk of replication by competitors.

Choosing the Right Solution: Key Decision Factors

Evaluating Custom Robots versus Off-the-shelf Robots involves key decision factors such as budget constraints, project requirements, and scalability needs. Custom Robots offer tailored functionality and integration for specialized tasks, whereas Off-the-shelf Robots provide quicker deployment and cost-efficiency for standard operations. Your choice depends on balancing customization demands with time-to-market and long-term maintenance considerations.

Custom Robot vs Off-the-shelf Robot Infographic

libmatt.com

libmatt.com