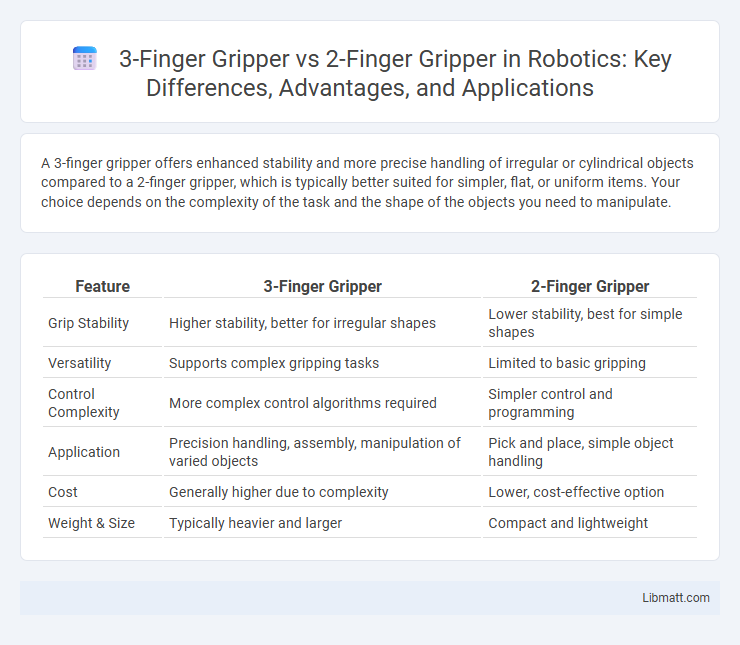

A 3-finger gripper offers enhanced stability and more precise handling of irregular or cylindrical objects compared to a 2-finger gripper, which is typically better suited for simpler, flat, or uniform items. Your choice depends on the complexity of the task and the shape of the objects you need to manipulate.

Table of Comparison

| Feature | 3-Finger Gripper | 2-Finger Gripper |

|---|---|---|

| Grip Stability | Higher stability, better for irregular shapes | Lower stability, best for simple shapes |

| Versatility | Supports complex gripping tasks | Limited to basic gripping |

| Control Complexity | More complex control algorithms required | Simpler control and programming |

| Application | Precision handling, assembly, manipulation of varied objects | Pick and place, simple object handling |

| Cost | Generally higher due to complexity | Lower, cost-effective option |

| Weight & Size | Typically heavier and larger | Compact and lightweight |

Introduction to Robotic Grippers

Robotic grippers are essential end-effectors designed to grasp, hold, and manipulate objects in automated systems, with 2-finger and 3-finger grippers being the most common types. A 2-finger gripper offers simplicity and is ideal for handling regular, flat, or prismatic objects, providing effective pinch grasp capabilities. In contrast, a 3-finger gripper provides enhanced versatility and stability, enabling it to securely grasp cylindrical and irregularly shaped objects through a more complex, adaptive grasp mechanism.

Overview: 3-Finger vs 2-Finger Grippers

3-finger grippers provide enhanced stability and versatility for handling irregularly shaped objects due to their three-point contact approach, which distributes gripping force more evenly compared to 2-finger grippers. 2-finger grippers are simpler, typically lightweight, and excel in applications requiring quick, precise grasping of uniformly shaped items, making them ideal for high-speed automation tasks. The choice between 3-finger and 2-finger grippers depends on the specific application requirements, such as object geometry, grip strength, and operational speed.

Design and Mechanical Structure Comparison

The 3-finger gripper features a symmetrical design with three equally spaced fingers, providing enhanced stability and uniform gripping force distribution, making it ideal for complex or irregular objects. In contrast, the 2-finger gripper utilizes a simpler, parallel finger mechanism suited for straightforward, linear gripping tasks, offering faster operation and easier maintenance. The mechanical structure of the 3-finger gripper often involves more intricate linkages or actuators for synchronized movement, whereas the 2-finger gripper generally relies on simpler pivot points or linear actuators for finger actuation.

Gripping Versatility and Dexterity

A 3-finger gripper offers enhanced gripping versatility and dexterity by providing three points of contact, enabling it to handle irregularly shaped objects and perform more complex manipulation tasks compared to a 2-finger gripper. The additional finger improves stability and precision, especially for cylindrical or spherical items, while a 2-finger gripper is typically better suited for simpler, flat, or regular-shaped objects with less need for intricate movements. This makes 3-finger grippers ideal for applications requiring adaptive gripping and fine motor skills in robotics and automation.

Load Capacity and Force Distribution

A 3-finger gripper offers superior load capacity compared to a 2-finger gripper due to its ability to evenly distribute force across three contact points, reducing stress on the object. This enhanced force distribution improves grip stability and precision, especially for irregularly shaped items, minimizing the risk of slippage or damage. Your choice between the two should consider the specific load requirements and the object's geometry to ensure optimal performance.

Application Suitability in Various Industries

3-finger grippers provide enhanced stability and precise handling for complex and irregularly shaped objects, making them ideal for industries such as electronics assembly and medical device manufacturing. In contrast, 2-finger grippers offer simplicity and speed, better suited for packaging, material handling, and automotive parts that require straightforward gripping actions. The choice between 3-finger and 2-finger grippers depends on the specific industry needs for accuracy, object geometry, and operational efficiency.

Precision and Accuracy in Object Handling

3-finger grippers provide enhanced precision and accuracy in object handling by offering multiple points of contact, which distribute gripping force evenly and reduce the risk of slippage. Their design enables better adaptability to irregularly shaped items, improving the stability and control needed for delicate or complex tasks. Your choice of a 3-finger gripper over a 2-finger model can significantly improve outcomes in applications that require careful manipulation and consistent alignment.

Integration and Compatibility with Robotics

3-finger grippers provide enhanced versatility and stability for complex robotic manipulation tasks, offering improved grip adaptability compared to 2-finger grippers. Integration with robotic arms is streamlined due to their modular designs and compatibility with standard robotic interfaces such as ROS (Robot Operating System) and common communication protocols like Ethernet/IP or CAN bus. While 2-finger grippers excel in simpler pick-and-place operations with lower hardware requirements, 3-finger grippers enable more sophisticated object handling in automation systems demanding precision and flexible grasping.

Cost, Maintenance, and Reliability Factors

A 3-finger gripper generally incurs higher initial costs compared to a 2-finger gripper due to its more complex design and increased number of components. Maintenance for 3-finger grippers tends to be more demanding, requiring frequent calibration and part replacements to ensure synchronized finger movement, whereas 2-finger grippers typically need less intensive upkeep. Reliability factors favor 2-finger grippers in simpler applications with consistent grips, while 3-finger grippers offer improved stability and versatility for handling irregularly shaped or delicate objects, albeit with potentially increased failure points.

Choosing the Right Gripper for Your Needs

Choosing the right gripper depends on the complexity and precision of your task, with 3-finger grippers offering enhanced stability and adaptability for irregular or delicate objects. Two-finger grippers excel in simple, precise gripping of uniform shapes, providing cost-effective and efficient solutions for standard applications. Assessing the object's shape, size, and handling requirements ensures optimal functionality and operational efficiency.

3-finger gripper vs 2-finger gripper Infographic

libmatt.com

libmatt.com