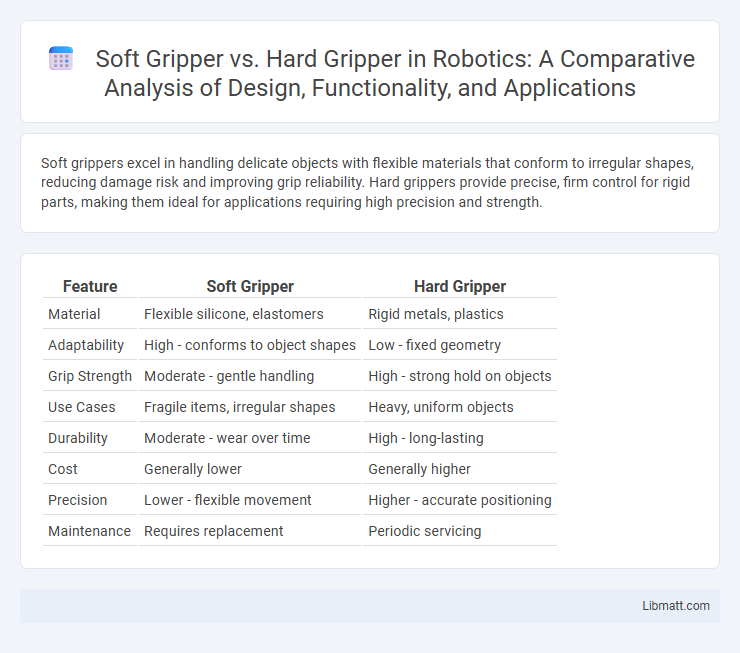

Soft grippers excel in handling delicate objects with flexible materials that conform to irregular shapes, reducing damage risk and improving grip reliability. Hard grippers provide precise, firm control for rigid parts, making them ideal for applications requiring high precision and strength.

Table of Comparison

| Feature | Soft Gripper | Hard Gripper |

|---|---|---|

| Material | Flexible silicone, elastomers | Rigid metals, plastics |

| Adaptability | High - conforms to object shapes | Low - fixed geometry |

| Grip Strength | Moderate - gentle handling | High - strong hold on objects |

| Use Cases | Fragile items, irregular shapes | Heavy, uniform objects |

| Durability | Moderate - wear over time | High - long-lasting |

| Cost | Generally lower | Generally higher |

| Precision | Lower - flexible movement | Higher - accurate positioning |

| Maintenance | Requires replacement | Periodic servicing |

Introduction to Soft and Hard Grippers

Soft grippers use flexible materials such as silicone or rubber to conform to object shapes, ideal for handling delicate or irregular items. Hard grippers are constructed from rigid metals or plastics, providing strong, precise grips suitable for heavy or well-defined objects. Understanding the distinct applications of soft and hard grippers is crucial for optimizing automation in robotics and manufacturing.

Key Differences Between Soft and Hard Grippers

Soft grippers use flexible materials like silicone to manipulate delicate or irregularly shaped objects safely, while hard grippers rely on rigid components to provide precise, strong, and repeatable gripping for firm objects. Soft grippers excel in adaptability and are often employed in industries like food handling and electronics, whereas hard grippers are suitable for heavy-duty tasks requiring high gripping force and durability. Understanding these key differences helps you select the appropriate gripper type based on object fragility, shape, and application needs.

Material Composition and Design

Soft grippers are made from flexible materials such as silicone, rubber, or other elastomers that allow them to conform to irregular shapes and provide gentle handling for delicate objects. Hard grippers are typically composed of rigid materials like metal or hard plastics, offering strong gripping force and precise control for robust tasks. Your choice between soft and hard grippers depends on the specific application requirements, balancing material compliance and mechanical strength.

Flexibility and Adaptability in Gripping

Soft grippers exhibit superior flexibility by conforming to irregularly shaped objects, reducing damage risk and improving handling of delicate items. Hard grippers provide precise control and strong grip force for rigid, uniform objects but lack adaptability to variable shapes. This contrast highlights soft grippers' advantage in tasks requiring adaptability and gentle manipulation, while hard grippers excel in applications demanding firmness and exact positioning.

Force Control and Grip Strength

Soft grippers excel in force control by adapting their shape to delicate objects, reducing the risk of damage while maintaining secure holds through compliant materials. Hard grippers offer higher grip strength with rigid construction and precise force application, ideal for handling heavy or robust items requiring consistent pressure. Your choice between these options depends on the specific task's need for gentle manipulation versus maximum grip force.

Application Areas: Soft vs Hard Grippers

Soft grippers excel in delicate applications such as handling fragile food items, textiles, and flexible electronics due to their adaptable, compliant materials that prevent damage. Hard grippers are preferred in industrial settings requiring precise, firm grasping of rigid components like metal parts, automotive assemblies, and heavy machinery, where strength and accuracy are critical. Your choice between soft and hard grippers depends on the specific requirements of handling sensitivity, object variability, and operational environment.

Safety and Damage Risk to Handled Objects

Soft grippers reduce damage risk to delicate or irregularly shaped objects by conforming gently to their surfaces, offering superior safety during handling tasks. Hard grippers provide stronger, more precise grasping for rigid and uniform items but pose a higher risk of crushing or scratching fragile materials. Using soft grippers enhances safety in applications involving sensitive products, while hard grippers are best suited for robust objects where precise force control is critical.

Cost and Maintenance Considerations

Soft grippers typically have lower initial costs due to simpler materials like silicone and fewer rigid parts, making them more budget-friendly for applications requiring delicate handling. Maintenance for soft grippers is generally easier and less expensive because flexible components reduce wear and tear, though frequent replacement may be necessary in abrasive environments. Hard grippers often incur higher costs upfront and require more intensive maintenance to manage mechanical joints and metal parts, but they tend to have longer service life in heavy-duty tasks.

Recent Innovations and Research Trends

Recent innovations in soft grippers emphasize materials with enhanced flexibility and adaptive capabilities, enabling delicate handling of irregular objects in robotics and automation. Hard grippers, benefiting from advancements in precision actuation and sensor integration, excel in tasks requiring strong, rigid grasping and durability under heavy loads. Your choice between soft and hard grippers should consider the balance between compliance for sensitive manipulation and strength for robust industrial applications, reflecting the latest research trends in smart materials and robotic control systems.

Choosing the Right Gripper for Your Application

Choosing the right gripper for your application depends on factors like object fragility, shape variability, and precision requirements. Soft grippers excel in handling delicate or irregularly shaped items with gentle, adaptive grasping, while hard grippers provide strong, rigid gripping for precise, repeatable tasks on uniform objects. Consider your product's material properties and handling environment to determine whether a soft or hard gripper best ensures efficiency and safety.

Soft Gripper vs Hard Gripper Infographic

libmatt.com

libmatt.com