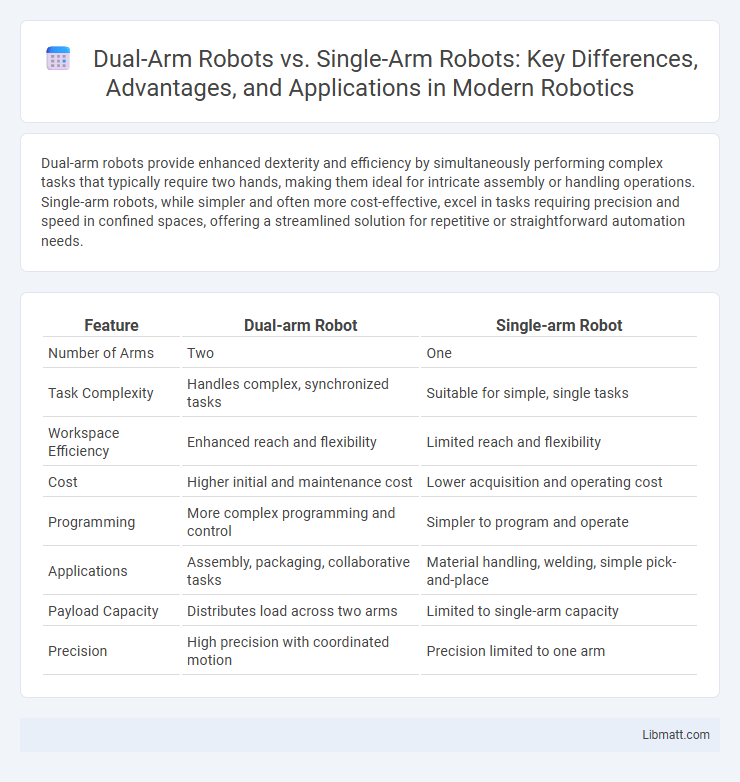

Dual-arm robots provide enhanced dexterity and efficiency by simultaneously performing complex tasks that typically require two hands, making them ideal for intricate assembly or handling operations. Single-arm robots, while simpler and often more cost-effective, excel in tasks requiring precision and speed in confined spaces, offering a streamlined solution for repetitive or straightforward automation needs.

Table of Comparison

| Feature | Dual-arm Robot | Single-arm Robot |

|---|---|---|

| Number of Arms | Two | One |

| Task Complexity | Handles complex, synchronized tasks | Suitable for simple, single tasks |

| Workspace Efficiency | Enhanced reach and flexibility | Limited reach and flexibility |

| Cost | Higher initial and maintenance cost | Lower acquisition and operating cost |

| Programming | More complex programming and control | Simpler to program and operate |

| Applications | Assembly, packaging, collaborative tasks | Material handling, welding, simple pick-and-place |

| Payload Capacity | Distributes load across two arms | Limited to single-arm capacity |

| Precision | High precision with coordinated motion | Precision limited to one arm |

Overview of Dual-arm and Single-arm Robots

Dual-arm robots feature two articulated arms that enable simultaneous manipulation of multiple objects or tasks, enhancing efficiency and precision in complex operations such as assembly, packaging, and welding. Single-arm robots utilize one arm designed for dedicated tasks typically requiring less coordination, making them ideal for simpler or more repetitive functions like pick-and-place or machine tending. Both configurations optimize robotic automation but differ significantly in versatility, workspace, and application complexity.

Key Differences Between Dual-arm and Single-arm Robots

Dual-arm robots offer enhanced dexterity and coordination by mimicking human bimanual tasks, enabling simultaneous handling of complex operations, whereas single-arm robots are typically suited for simpler, repetitive tasks with limited reach and flexibility. The key differences include payload capacity, workspace manipulation, and task complexity, where dual-arm systems excel in collaborative manufacturing and assembly lines. Your choice depends on the precision, speed, and operational demands required for specific automation processes.

Applications of Dual-arm Robots

Dual-arm robots are widely used in complex industrial automation tasks such as assembly, welding, and material handling, where simultaneous coordination of both arms improves precision and efficiency. These robots excel in environments requiring human-like dexterity, enabling them to perform intricate tasks like packaging, machine tending, and collaborative operations with humans. Your manufacturing processes can benefit from dual-arm robots by increasing throughput and reducing cycle times compared to single-arm counterparts.

Applications of Single-arm Robots

Single-arm robots excel in applications requiring precise, repetitive tasks such as assembly, welding, and material handling within manufacturing environments. These robots offer flexibility and cost-effectiveness for tasks where one manipulator suffices, making them ideal for conveyor systems, packaging, and inspection processes. Your production line can benefit from their adaptability and efficiency when a single arm meets operational demands.

Advantages of Dual-arm Robots

Dual-arm robots offer enhanced dexterity and coordination, enabling complex tasks that require simultaneous manipulation of multiple objects, which single-arm robots struggle to perform efficiently. Their ability to mimic human bimanual operations improves automation in industries such as manufacturing, assembly, and logistics by increasing productivity and reducing cycle times. The synchronized control of dual arms also allows for better spatial awareness and handling of larger or more flexible workpieces, leading to improved operational flexibility and precision.

Benefits of Single-arm Robots

Single-arm robots offer greater simplicity and cost-effectiveness compared to dual-arm robots, making them ideal for tasks requiring precision and speed in confined spaces. Their compact design facilitates easier integration into existing production lines, enhancing efficiency without extensive modification. You can rely on single-arm robots for specialized applications like pick-and-place, assembly, and packaging, where a single manipulator is sufficient.

Cost Comparison: Dual-arm vs Single-arm Robots

Dual-arm robots typically have higher initial costs compared to single-arm robots due to their complex mechanics and advanced control systems, which require more sophisticated programming and sensors. However, dual-arm systems can improve operational efficiency by performing simultaneous tasks, potentially reducing labor costs and cycle times in manufacturing environments. Single-arm robots have lower upfront expenses and simpler maintenance requirements, making them more cost-effective for straightforward, repetitive processes with limited workspace.

Flexibility and Versatility Analysis

Dual-arm robots offer enhanced flexibility by simultaneously performing complex tasks that require coordination between two manipulators, significantly improving efficiency in assembly and handling operations. Single-arm robots, while simpler and more cost-effective, have limited versatility when managing multi-step processes or tasks requiring synchronized movements. The dual-arm configuration allows for greater adaptability in dynamic environments, making them ideal for industries demanding high precision and multitasking capabilities.

Challenges and Limitations of Each Type

Dual-arm robots face challenges in coordinating precise, synchronized movements, often requiring complex control algorithms to avoid collisions and ensure smooth operation. Single-arm robots have limitations in handling tasks that require simultaneous multi-point manipulation or high dexterity, which can restrict their efficiency in complex assembly or packaging processes. Your choice between these robot types should consider task complexity, workspace constraints, and the required level of manipulation to optimize performance and cost-effectiveness.

Choosing the Right Robot for Industrial Needs

Dual-arm robots offer enhanced flexibility and productivity by simultaneously performing complex tasks that require coordinated movements, making them ideal for intricate assembly lines and heavy-duty industrial applications. Single-arm robots provide precision and simplicity, suitable for repetitive or straightforward tasks where space and cost efficiency are priorities. Evaluating your production requirements, including task complexity, workspace constraints, and budget, ensures you select the right robot to optimize operational efficiency.

Dual-arm Robot vs Single-arm Robot Infographic

libmatt.com

libmatt.com