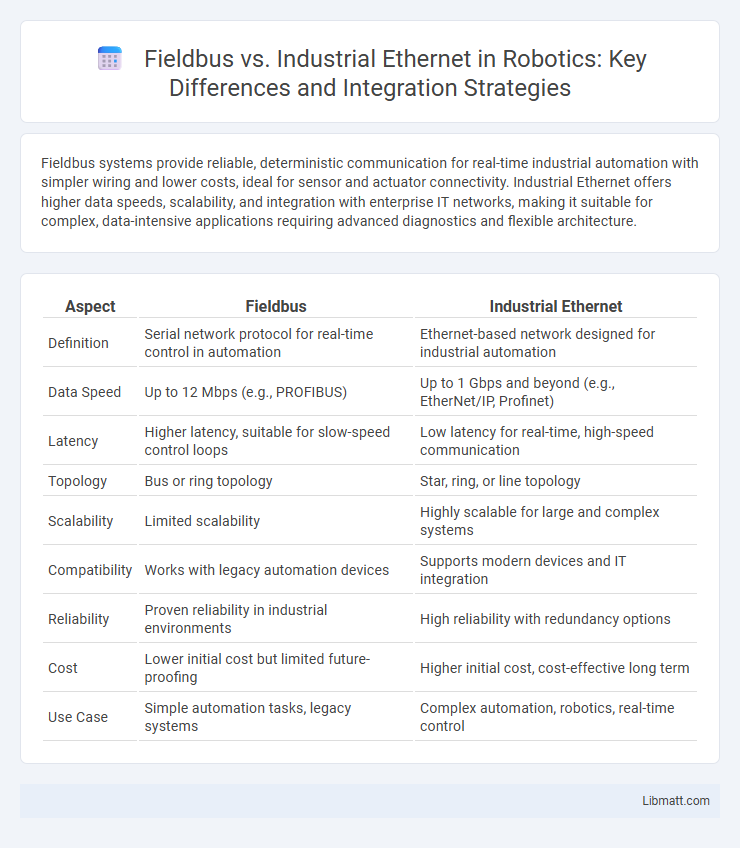

Fieldbus systems provide reliable, deterministic communication for real-time industrial automation with simpler wiring and lower costs, ideal for sensor and actuator connectivity. Industrial Ethernet offers higher data speeds, scalability, and integration with enterprise IT networks, making it suitable for complex, data-intensive applications requiring advanced diagnostics and flexible architecture.

Table of Comparison

| Aspect | Fieldbus | Industrial Ethernet |

|---|---|---|

| Definition | Serial network protocol for real-time control in automation | Ethernet-based network designed for industrial automation |

| Data Speed | Up to 12 Mbps (e.g., PROFIBUS) | Up to 1 Gbps and beyond (e.g., EtherNet/IP, Profinet) |

| Latency | Higher latency, suitable for slow-speed control loops | Low latency for real-time, high-speed communication |

| Topology | Bus or ring topology | Star, ring, or line topology |

| Scalability | Limited scalability | Highly scalable for large and complex systems |

| Compatibility | Works with legacy automation devices | Supports modern devices and IT integration |

| Reliability | Proven reliability in industrial environments | High reliability with redundancy options |

| Cost | Lower initial cost but limited future-proofing | Higher initial cost, cost-effective long term |

| Use Case | Simple automation tasks, legacy systems | Complex automation, robotics, real-time control |

Introduction to Fieldbus and Industrial Ethernet

Fieldbus is a digital industrial network protocol designed for real-time distributed control, enabling communication between field devices and control systems in manufacturing environments. Industrial Ethernet, meanwhile, extends standard Ethernet technology to meet industrial requirements, offering higher data speeds, enhanced reliability, and real-time capabilities for complex automation systems. Your choice between Fieldbus and Industrial Ethernet depends on specific application needs such as network size, data rate, and system integration complexity.

Key Differences Between Fieldbus and Industrial Ethernet

Fieldbus uses serial communication protocols designed for real-time, deterministic data exchange in industrial automation, while Industrial Ethernet leverages standard Ethernet protocols offering higher bandwidth and greater scalability for complex networks. Fieldbus systems are often limited to slower data rates and segment lengths, whereas Industrial Ethernet enables faster speeds, extended distances, and integration with IT infrastructure. Industrial Ethernet supports a wider range of devices and applications through its open architecture, making it suitable for modern Industry 4.0 environments compared to the more specialized, legacy Fieldbus technologies.

Historical Evolution of Industrial Communication Protocols

Fieldbus technology emerged in the 1980s as a revolutionary digital communication protocol designed to replace traditional analog wiring in industrial automation systems, enabling decentralized control and real-time data exchange among field devices. Industrial Ethernet evolved in the 1990s, leveraging standard Ethernet technology enhanced with real-time capabilities and robust protocols such as PROFINET, EtherNet/IP, and Modbus TCP to meet the increasing demand for higher bandwidth and seamless integration with IT networks. The progression from Fieldbus to Industrial Ethernet reflects the shift towards interoperable, scalable, and high-performance communication infrastructures essential for modern Industry 4.0 applications.

Technical Architecture Comparison

Fieldbus systems utilize a serial communication protocol with a bus topology optimized for real-time control and low bandwidth requirements, incorporating master-slave or token-passing mechanisms to manage device communication. Industrial Ethernet employs standard Ethernet protocols enhanced with real-time extensions such as PROFINET, EtherCAT, and Modbus TCP, supporting higher data rates, peer-to-peer communication, and flexible star or ring topologies for scalability and redundancy. The technical architecture of Industrial Ethernet offers superior bandwidth, deterministic communication, and seamless integration with IT networks compared to Fieldbus's specialized but limited network approach tailored for simple device connectivity.

Performance and Speed Analysis

Industrial Ethernet offers significantly higher data transfer rates, reaching up to 1 Gbps or more, compared to Fieldbus systems, which typically operate at speeds below 1 Mbps. The low latency and deterministic performance of Industrial Ethernet enhance real-time communication crucial for complex automation processes, while Fieldbus provides reliable but slower connections suited for simpler control tasks. Your choice between the two should consider the application's demand for speed, network size, and the complexity of data exchange required.

Scalability and Flexibility

Fieldbus systems offer limited scalability and flexibility due to their fixed topology and lower data capacity, making them suitable for smaller, simpler industrial networks. Industrial Ethernet provides superior scalability and flexibility with high data transfer rates and support for complex network structures, allowing seamless integration of diverse devices and future expansions. Your industrial processes benefit from Industrial Ethernet's adaptability to evolving communication needs and enhanced network management capabilities.

Reliability and Determinism

Fieldbus systems provide high reliability and deterministic communication through time-triggered protocols with fixed cycling, ensuring predictable data transfer in industrial automation. Industrial Ethernet offers improved bandwidth and scalability but requires additional real-time communication protocols like PROFINET or EtherCAT to achieve similar determinism and reliability. Deterministic Industrial Ethernet implementations deliver low latency and jitter, making them suitable for precise control tasks in complex manufacturing environments.

Integration with Modern Industrial Systems

Fieldbus networks, traditionally used for device-level communication in industrial automation, face limitations in bandwidth and scalability compared to Industrial Ethernet, which supports higher data rates and seamless integration with modern IT infrastructures. Industrial Ethernet enables real-time data exchange, enhanced diagnostics, and interoperability with cloud-based systems, facilitating Industry 4.0 implementations and smart manufacturing. Its compatibility with standard TCP/IP protocols and extensive device ecosystem allows streamlined connectivity across sensors, controllers, and enterprise systems, making it the preferred choice for modern industrial environments.

Cost Considerations

Fieldbus systems generally have lower initial installation costs due to simpler cabling and device requirements, making them cost-effective for small to medium-sized industrial setups. Industrial Ethernet offers higher scalability and faster data transmission, but its advanced infrastructure and hardware can lead to increased upfront expenses and maintenance costs. Your choice between Fieldbus and Industrial Ethernet should balance budget constraints with the need for network performance and future expansion.

Future Trends in Industrial Networking

Industrial Ethernet is rapidly emerging as the dominant technology due to its higher data transfer speeds, scalability, and seamless integration with existing IT infrastructure compared to traditional Fieldbus systems. Future trends emphasize the convergence of Industrial Ethernet with Time-Sensitive Networking (TSN) standards to ensure deterministic communication and enhanced real-time control in Industry 4.0 environments. The adoption of Industrial Internet of Things (IIoT) devices and cloud-based analytics further accelerates this shift, driving a move toward more flexible, intelligent, and interoperable industrial networking solutions.

Fieldbus vs Industrial Ethernet Infographic

libmatt.com

libmatt.com