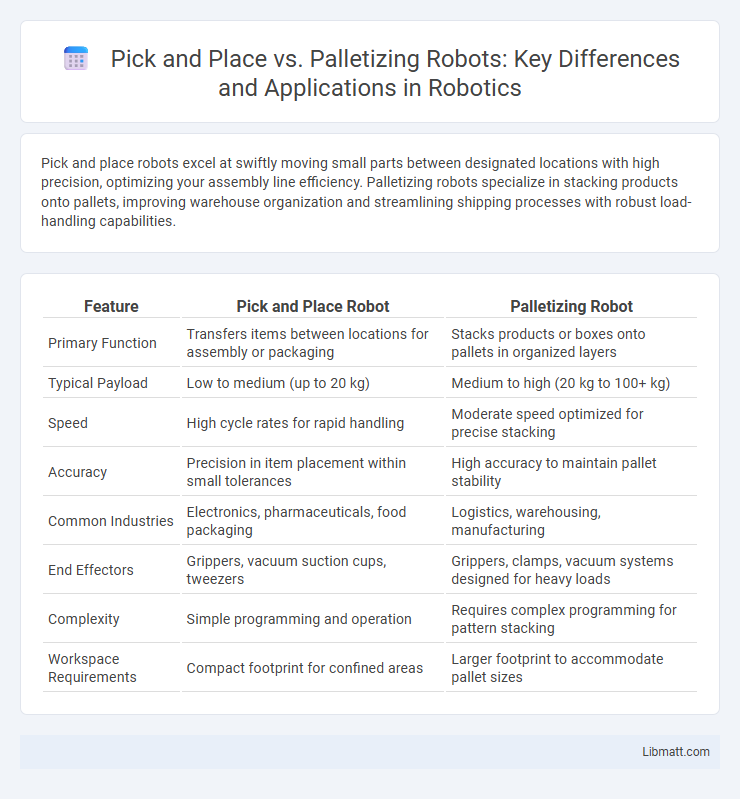

Pick and place robots excel at swiftly moving small parts between designated locations with high precision, optimizing your assembly line efficiency. Palletizing robots specialize in stacking products onto pallets, improving warehouse organization and streamlining shipping processes with robust load-handling capabilities.

Table of Comparison

| Feature | Pick and Place Robot | Palletizing Robot |

|---|---|---|

| Primary Function | Transfers items between locations for assembly or packaging | Stacks products or boxes onto pallets in organized layers |

| Typical Payload | Low to medium (up to 20 kg) | Medium to high (20 kg to 100+ kg) |

| Speed | High cycle rates for rapid handling | Moderate speed optimized for precise stacking |

| Accuracy | Precision in item placement within small tolerances | High accuracy to maintain pallet stability |

| Common Industries | Electronics, pharmaceuticals, food packaging | Logistics, warehousing, manufacturing |

| End Effectors | Grippers, vacuum suction cups, tweezers | Grippers, clamps, vacuum systems designed for heavy loads |

| Complexity | Simple programming and operation | Requires complex programming for pattern stacking |

| Workspace Requirements | Compact footprint for confined areas | Larger footprint to accommodate pallet sizes |

Introduction to Pick and Place vs Palletizing Robots

Pick and Place robots specialize in quickly and accurately transferring individual items from one location to another, optimizing assembly lines and packaging processes. Palletizing robots handle heavier loads by stacking products onto pallets for storage or shipping, improving warehouse and logistics efficiency. Both types utilize advanced robotics technology but serve distinct roles in automation, focusing on precision placement versus bulk handling.

Key Differences Between Pick and Place and Palletizing Robots

Pick and Place and Palletizing Robots differ primarily in their operational scope and application complexity, with Pick and Place Robots focusing on precise, repetitive object transfer tasks often in assembly or packaging lines, while Palletizing Robots are designed to stack items efficiently on pallets for shipping or storage. The key differences lie in their payload capacity as Palletizing Robots handle heavier loads, and motion range, as they typically require larger workspaces and more robust programming for diverse stacking patterns. Your choice between these robots should consider task specificity, load requirements, and integration with existing automation systems to optimize productivity.

Core Functions of Pick and Place Robots

Pick and Place robots specialize in the precise movement of objects from one location to another, handling tasks such as assembly, packaging, and sorting with high speed and accuracy. These robots use advanced vision systems and end effectors to identify, grasp, and relocate items, optimizing production lines and reducing human error. Their core functions include object recognition, gripping, and placement, which enable efficient automation in industries like electronics, food processing, and pharmaceuticals.

Core Functions of Palletizing Robots

Palletizing robots specialize in organizing products or packages into stacks or layers on pallets for efficient storage and transport. These robots excel in high-speed, repetitive tasks, ensuring precise placement and maximizing pallet space utilization. Core functions include handling various pallet patterns, load stabilization, and automated layer formation to streamline warehouse logistics.

Industries Utilizing Pick and Place Robots

Pick and place robots are widely utilized across industries such as electronics manufacturing, pharmaceuticals, food and beverage, and automotive assembly for their precision in handling small parts and components. These robots streamline processes like packaging, sorting, and assembly, significantly increasing operational efficiency and reducing labor costs. High-speed applications in semiconductor production and consumer goods packaging highlight the adaptability of pick and place technology in diverse industrial environments.

Industries Benefiting from Palletizing Robots

Palletizing robots are extensively utilized in industries such as food and beverage, pharmaceuticals, manufacturing, and logistics for automating the stacking and organization of products on pallets, enhancing efficiency and reducing labor costs. These robots handle heavy loads and repetitive tasks with precision, improving workplace safety and throughput in warehouses and distribution centers. Your operations can benefit from palletizing robots by streamlining pallet organization and accelerating order fulfillment processes.

Efficiency and Speed Comparison

Pick and Place robots excel in high-speed, repetitive tasks with cycle times as low as 1-2 seconds per operation, making them ideal for rapid sorting and assembly processes. Palletizing robots handle heavier loads and larger payloads but operate at slower speeds, typically completing cycles in 5-10 seconds due to complex stacking patterns. Efficiency in Pick and Place systems is driven by precision and minimal movement, whereas Palletizing robots prioritize load stability and spatial optimization, impacting overall throughput differently.

Cost Analysis: Pick and Place vs Palletizing

Pick and Place robots generally have a lower initial cost compared to Palletizing robots due to their simpler design and specialized function in handling small, precise movements. Palletizing robots, designed for heavy lifting and stacking tasks, require more robust hardware and complex programming, leading to higher acquisition and maintenance expenses. Evaluating Your specific application needs and production volume helps determine which robotic solution offers the best return on investment.

Integration and Automation Challenges

Pick and place robots require precise integration with existing conveyor systems and sensors to ensure accurate handling of varied items, which can complicate synchronization efforts. Palletizing robots face automation challenges such as managing heavy payloads, maintaining stacking stability, and adapting to diverse pallet sizes, demanding robust programming and advanced vision systems. Your automation strategy must address these integration nuances to optimize workflow efficiency and minimize downtime.

Choosing the Right Robot for Your Application

Selecting the right robot depends on your specific production needs and workflow demands. Pick and place robots excel in high-speed, precise handling of small components, ideal for assembly and packaging tasks, while palletizing robots are designed for stacking, organizing, and loading heavy or large products onto pallets. Understanding the load capacity, operational speed, and spatial requirements of Your application ensures optimal efficiency and return on investment.

Pick and Place vs Palletizing Robot Infographic

libmatt.com

libmatt.com