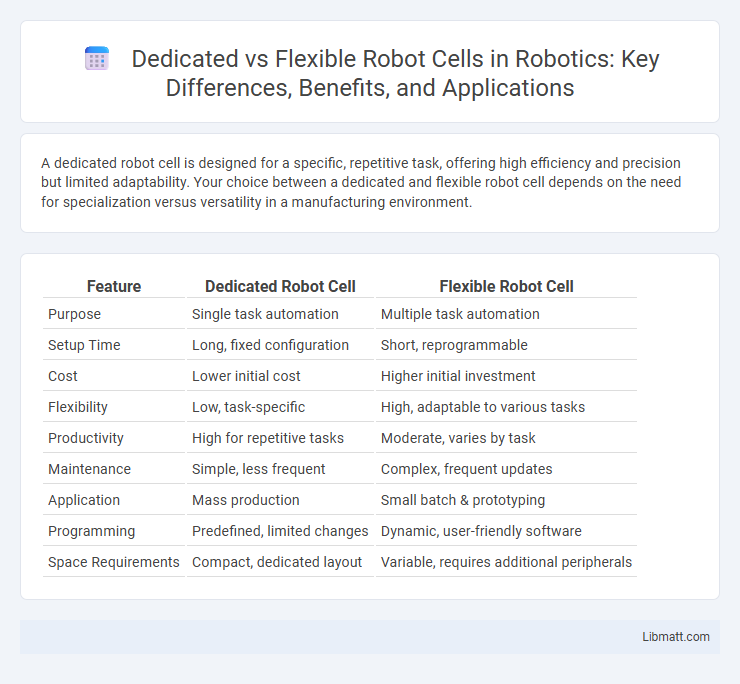

A dedicated robot cell is designed for a specific, repetitive task, offering high efficiency and precision but limited adaptability. Your choice between a dedicated and flexible robot cell depends on the need for specialization versus versatility in a manufacturing environment.

Table of Comparison

| Feature | Dedicated Robot Cell | Flexible Robot Cell |

|---|---|---|

| Purpose | Single task automation | Multiple task automation |

| Setup Time | Long, fixed configuration | Short, reprogrammable |

| Cost | Lower initial cost | Higher initial investment |

| Flexibility | Low, task-specific | High, adaptable to various tasks |

| Productivity | High for repetitive tasks | Moderate, varies by task |

| Maintenance | Simple, less frequent | Complex, frequent updates |

| Application | Mass production | Small batch & prototyping |

| Programming | Predefined, limited changes | Dynamic, user-friendly software |

| Space Requirements | Compact, dedicated layout | Variable, requires additional peripherals |

Introduction to Robot Cell Automation

Dedicated robot cells are designed for specific, repetitive tasks with optimized layouts and tooling, resulting in high efficiency and consistent performance. Flexible robot cells offer adaptability to various tasks and products by integrating modular components and programmable controls, allowing quick reconfiguration for changing production needs. Your choice between dedicated and flexible cells depends on production volume, variability, and the need for automation scalability in your manufacturing process.

Definition of Dedicated Robot Cell

A Dedicated Robot Cell is a robotic system designed to perform a specific, repetitive task within a fixed production environment, ensuring high efficiency and precision. Unlike Flexible Robot Cells that can be reprogrammed for multiple applications, Dedicated Robot Cells typically have fixed tooling and programming tailored to a single operation. This makes Dedicated Robot Cells ideal for high-volume manufacturing processes requiring consistent output and minimal changeover time.

Definition of Flexible Robot Cell

A Flexible Robot Cell is an advanced automation setup designed to handle multiple tasks and adapt to varying production requirements through programmable configurations and interchangeable tools. Unlike a Dedicated Robot Cell, which is optimized for a single repetitive task, a Flexible Robot Cell increases efficiency by enabling rapid changeovers and supporting diverse product lines. Your manufacturing process benefits from its versatility, reducing downtime and improving responsiveness to market demands.

Key Differences Between Dedicated and Flexible Robot Cells

Dedicated robot cells are designed for specific, repetitive tasks with fixed configurations, offering high-speed performance and consistent precision ideal for mass production. Flexible robot cells accommodate multiple tasks and adapt quickly to new workflows through programmable robots and modular tooling, enhancing versatility in dynamic manufacturing environments. Your choice depends on whether you prioritize efficiency and uniformity with dedicated cells or adaptability and customization with flexible cells.

Advantages of Dedicated Robot Cells

Dedicated robot cells provide superior efficiency and precision by performing specific, repetitive tasks with optimized programming and tooling, reducing cycle times and minimizing errors. Their specialized design leads to higher throughput and consistent product quality, which is essential in high-volume manufacturing environments. Maintenance and troubleshooting are simplified due to the focused scope, resulting in reduced downtime and operational costs.

Advantages of Flexible Robot Cells

Flexible robot cells offer significant advantages such as adaptability to various tasks, reducing downtime and increasing overall productivity. Their reprogrammable nature allows for quick changeovers, optimizing Your manufacturing processes and lowering operational costs. Enhanced scalability and ease of integration with existing systems make flexible robot cells ideal for dynamic production environments.

Application Scenarios for Each Robot Cell Type

Dedicated robot cells are ideal for high-volume, repetitive manufacturing tasks such as automotive assembly lines where consistency and speed are critical. Flexible robot cells suit production environments requiring frequent product changes or low to medium batch sizes, often found in electronics manufacturing or custom packaging. Each type optimizes operational efficiency by aligning with specific industry requirements and workflow variability.

Cost and ROI Considerations

Dedicated robot cells typically involve higher upfront capital expenditure due to specialized equipment tailored for a single task, resulting in faster ROI when production volumes are stable and predictable. Flexible robot cells offer lower initial costs and greater adaptability to multiple tasks, but may yield longer ROI periods because of increased programming complexity and potential downtime during reconfiguration. Evaluating cost-effectiveness requires analyzing production volume, variability, and the speed at which robot cell retooling impacts overall operational efficiency.

Choosing the Right Robot Cell for Your Needs

Choosing the right robot cell depends on your production requirements and flexibility demands. Dedicated robot cells excel in high-volume, repetitive tasks with minimal variation, offering optimized efficiency and precision for specific applications. Flexible robot cells provide adaptability to handle diverse products and tasks, enabling rapid reprogramming and scalability to meet changing manufacturing needs while maintaining productivity.

Future Trends in Robotic Cell Automation

Dedicated Robot Cells offer high efficiency in repetitive tasks with optimized performance, while Flexible Robot Cells provide adaptability for various applications, supporting rapid reconfiguration and integration of advanced AI-driven control systems. Future trends emphasize increased use of collaborative robots (cobots), enhanced sensor fusion, and cloud-based monitoring to enable predictive maintenance and real-time process optimization. Your manufacturing setup can benefit from these innovations by selecting robotic cell types that align with evolving production demands and Industry 4.0 strategies.

Dedicated Robot Cell vs Flexible Robot Cell Infographic

libmatt.com

libmatt.com