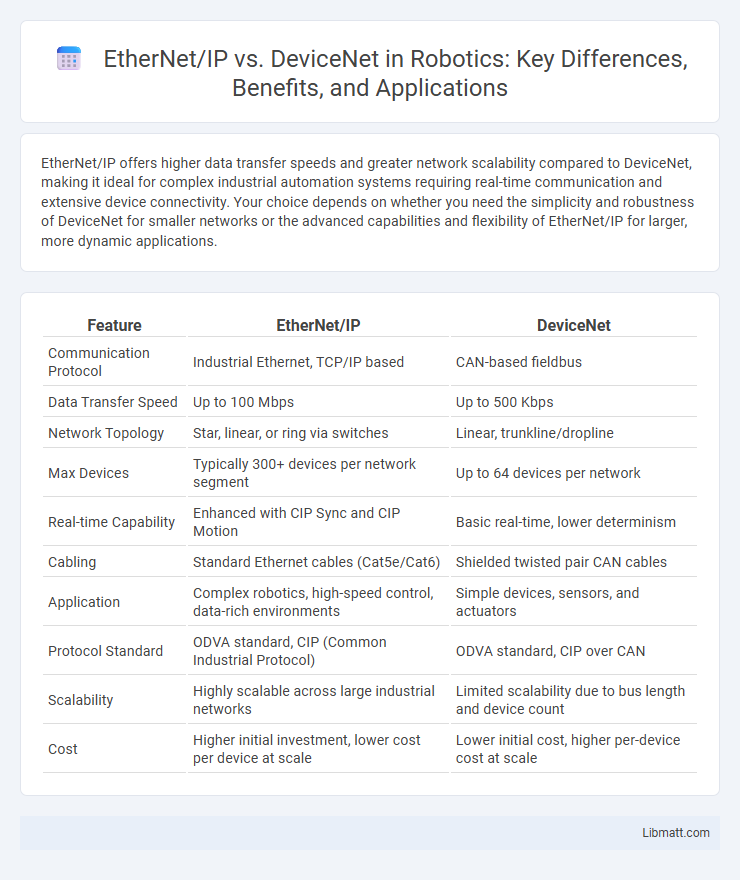

EtherNet/IP offers higher data transfer speeds and greater network scalability compared to DeviceNet, making it ideal for complex industrial automation systems requiring real-time communication and extensive device connectivity. Your choice depends on whether you need the simplicity and robustness of DeviceNet for smaller networks or the advanced capabilities and flexibility of EtherNet/IP for larger, more dynamic applications.

Table of Comparison

| Feature | EtherNet/IP | DeviceNet |

|---|---|---|

| Communication Protocol | Industrial Ethernet, TCP/IP based | CAN-based fieldbus |

| Data Transfer Speed | Up to 100 Mbps | Up to 500 Kbps |

| Network Topology | Star, linear, or ring via switches | Linear, trunkline/dropline |

| Max Devices | Typically 300+ devices per network segment | Up to 64 devices per network |

| Real-time Capability | Enhanced with CIP Sync and CIP Motion | Basic real-time, lower determinism |

| Cabling | Standard Ethernet cables (Cat5e/Cat6) | Shielded twisted pair CAN cables |

| Application | Complex robotics, high-speed control, data-rich environments | Simple devices, sensors, and actuators |

| Protocol Standard | ODVA standard, CIP (Common Industrial Protocol) | ODVA standard, CIP over CAN |

| Scalability | Highly scalable across large industrial networks | Limited scalability due to bus length and device count |

| Cost | Higher initial investment, lower cost per device at scale | Lower initial cost, higher per-device cost at scale |

Introduction to EtherNet/IP and DeviceNet

EtherNet/IP is an industrial network protocol that leverages standard Ethernet technology to ensure high-speed communication and interoperability among automation devices in industrial environments. DeviceNet, based on the Controller Area Network (CAN) protocol, provides a cost-effective and robust solution for connecting industrial control devices such as sensors and actuators within a localized network. Both protocols are widely used in manufacturing automation, with EtherNet/IP offering greater bandwidth and scalability, while DeviceNet emphasizes simplicity and real-time control.

Key Differences Between EtherNet/IP and DeviceNet

EtherNet/IP operates on standard Ethernet protocols, offering higher data transmission speeds up to 100 Mbps and extensive network scalability compared to DeviceNet's slower, CAN-based communication at 500 Kbps. EtherNet/IP supports larger network sizes and complex topologies, while DeviceNet is designed for simpler, smaller automation networks with integrated device-level control. Your choice depends on the need for speed, network complexity, and interoperability within industrial automation systems.

Network Topology and Architecture

EtherNet/IP uses a standard Ethernet network topology, supporting star, tree, or linear architectures with high-speed communication and scalability, ideal for complex industrial automation systems. DeviceNet relies on a Controller Area Network (CAN) bus topology, typically in a linear or trunkline-dropline structure, suited for cost-effective, lower-speed device-level networking. Your choice depends on the need for Ethernet's bandwidth and flexibility or DeviceNet's simplicity and reliability in smaller networks.

Data Transmission Speed and Bandwidth

EtherNet/IP offers significantly higher data transmission speeds, operating at 100 Mbps to 1 Gbps, compared to DeviceNet's maximum of 500 Kbps, making it ideal for bandwidth-intensive industrial applications. EtherNet/IP supports larger and more frequent data exchanges, providing greater bandwidth capacity for complex automation networks. Understanding these differences helps you choose the appropriate protocol based on your network speed and data throughput requirements.

Scalability and Network Expansion

EtherNet/IP offers superior scalability and network expansion capabilities compared to DeviceNet, supporting thousands of nodes and integrating easily with existing Ethernet infrastructure. DeviceNet typically supports fewer devices, often limited to 64 nodes per network segment, making large-scale deployments more complex. The use of standard IP addressing and higher bandwidth in EtherNet/IP facilitates seamless network growth and higher data throughput, crucial for expansive industrial automation systems.

Integration with Industrial Protocols

EtherNet/IP offers seamless integration with standard TCP/IP networks, supporting high-speed data transfer and compatibility with various industrial protocols such as CIP, OPC UA, and Modbus TCP. DeviceNet, based on the CAN bus protocol, provides reliable communication for device-level integration but has limited bandwidth and slower data rates compared to EtherNet/IP. EtherNet/IP's ability to handle complex, real-time control applications makes it more versatile for modern industrial automation environments requiring extensive protocol interoperability.

Security Features Comparison

EtherNet/IP offers advanced security features including support for IPsec encryption, robust firewall integration, and user authentication protocols, providing a higher level of protection against cyber threats compared to DeviceNet. DeviceNet primarily relies on its proprietary protocol with limited native security measures, making it more vulnerable to unauthorized access and attacks. Your industrial network benefits from EtherNet/IP's enhanced security capabilities, ensuring safer data transmission and better compliance with modern cybersecurity standards.

Cost Considerations and Implementation

EtherNet/IP generally incurs higher initial setup costs due to advanced hardware and infrastructure requirements compared to DeviceNet, which offers a more economical solution for smaller networks with simpler devices. Implementation of EtherNet/IP involves integrating standard Ethernet technology that supports higher bandwidth and scalability, making it suitable for complex automation systems. DeviceNet features simpler wiring and device addressing, reducing installation time and cost for less demanding applications, though it may face limitations in data throughput and network expansion.

Application Areas and Industry Use Cases

EtherNet/IP excels in large-scale industrial automation applications such as automotive assembly lines, food and beverage processing, and smart manufacturing due to its high-speed data transfer and seamless integration with IT networks. DeviceNet is widely used in smaller-scale machinery and equipment control, including packaging systems and conveyor networks, where cost-effectiveness and simplicity are paramount. Your choice between EtherNet/IP and DeviceNet should consider the complexity and scale of your automation project, as well as the specific communication requirements within your industry.

Future Trends in Industrial Networking

EtherNet/IP is increasingly favored for future industrial networking due to its higher bandwidth capabilities and seamless integration with standard Ethernet infrastructure, supporting advanced IoT applications and Industry 4.0 initiatives. DeviceNet, while reliable for lower-speed and simpler control systems, faces limitations in scalability and data throughput compared to EtherNet/IP's support for real-time communication and cloud connectivity. Your industrial network will benefit from adopting EtherNet/IP to leverage future trends like enhanced cybersecurity, edge computing, and predictive maintenance.

EtherNet/IP vs DeviceNet Infographic

libmatt.com

libmatt.com