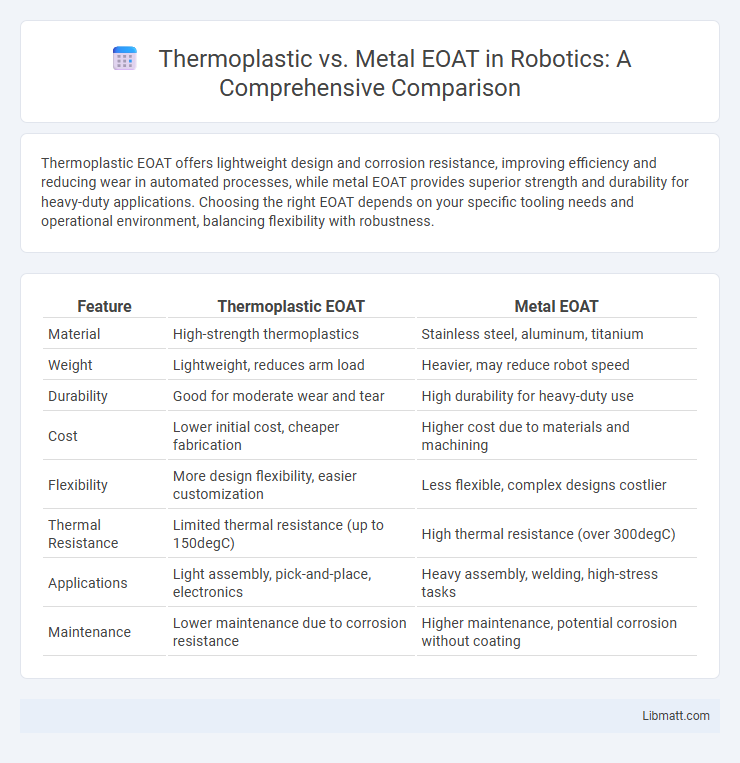

Thermoplastic EOAT offers lightweight design and corrosion resistance, improving efficiency and reducing wear in automated processes, while metal EOAT provides superior strength and durability for heavy-duty applications. Choosing the right EOAT depends on your specific tooling needs and operational environment, balancing flexibility with robustness.

Table of Comparison

| Feature | Thermoplastic EOAT | Metal EOAT |

|---|---|---|

| Material | High-strength thermoplastics | Stainless steel, aluminum, titanium |

| Weight | Lightweight, reduces arm load | Heavier, may reduce robot speed |

| Durability | Good for moderate wear and tear | High durability for heavy-duty use |

| Cost | Lower initial cost, cheaper fabrication | Higher cost due to materials and machining |

| Flexibility | More design flexibility, easier customization | Less flexible, complex designs costlier |

| Thermal Resistance | Limited thermal resistance (up to 150degC) | High thermal resistance (over 300degC) |

| Applications | Light assembly, pick-and-place, electronics | Heavy assembly, welding, high-stress tasks |

| Maintenance | Lower maintenance due to corrosion resistance | Higher maintenance, potential corrosion without coating |

Introduction to EOAT: Thermoplastic vs Metal

Thermoplastic EOAT offers lightweight flexibility and corrosion resistance, making it ideal for applications requiring reduced weight and easy customization. Metal EOAT provides superior strength, durability, and high-temperature resistance, suited for heavy-duty tasks and harsh environments. Your choice depends on balancing the need for resilience with the benefits of weight and adaptability in your automation process.

Material Composition and Properties

Thermoplastic EOAT (End Of Arm Tooling) is composed of polymer-based materials characterized by lightweight, corrosion resistance, and flexibility, making it ideal for applications requiring reduced weight and impact absorption. Metal EOAT, typically made from steel or aluminum alloys, offers superior strength, heat resistance, and durability, suitable for heavy-duty industrial processes and high-temperature environments. The choice between thermoplastic and metal EOAT depends on the balance between weight constraints and mechanical performance demands.

Weight Differences and Impact on Automation

Thermoplastic EOATs typically weigh significantly less than metal EOATs, reducing the load on robotic arms and enabling faster cycle times in automation processes. The lighter weight of thermoplastic EOATs decreases energy consumption and wear on machinery, enhancing overall system efficiency and maintenance intervals. Your automation setup can benefit from improved speed and reduced operational costs by opting for thermoplastic EOATs over traditional metal options.

Cost Comparison: Initial Investment and Maintenance

Thermoplastic EOAT generally requires a lower initial investment due to reduced material and manufacturing costs compared to metal EOAT. Maintenance expenses for thermoplastic EOAT are also typically lower since these tools resist corrosion and wear, reducing the frequency of repairs and replacements. Metal EOAT involves higher upfront costs and ongoing maintenance due to susceptibility to rust, fatigue, and potential need for specialized machining.

Durability and Lifespan Analysis

Thermoplastic EOAT offers excellent corrosion resistance and flexibility but generally has a shorter lifespan compared to Metal EOAT, which excels in durability and wear resistance under high-stress industrial applications. Metal EOAT withstands extreme temperatures and mechanical impacts better, making it ideal for heavy-duty, long-term use. Your choice should balance operational demands and budget considerations to optimize EOAT lifespan and performance.

Design Flexibility and Customization

Thermoplastic EOAT offers superior design flexibility and customization due to its ease of molding into complex geometries and rapid prototyping capabilities, enabling tailored solutions for specific applications. Metal EOAT, while highly durable and capable of withstanding extreme loads, often requires extensive machining processes that limit rapid design iterations and customization. The ability to quickly adapt thermoplastic EOAT designs accelerates innovation and reduces production lead times compared to the more rigid and time-intensive metal EOAT customization.

Performance in High-Speed Applications

Thermoplastic EOAT offers superior flexibility and weight reduction, enabling faster cycle times and lower inertia in high-speed applications compared to metal EOAT. Metal EOAT provides excellent strength and durability but often suffers from increased mass, leading to slower accelerations and potential wear under rapid motion. Optimizing tooling design with thermoplastics enhances precision and efficiency in automated processes, making them preferable for dynamic, high-speed operations.

Environmental Sustainability and Recycling

Thermoplastic EOATs offer superior environmental sustainability due to their recyclability and lower energy consumption during manufacturing compared to metal EOATs. The ability to remelt and reuse thermoplastic materials reduces waste and lowers the carbon footprint associated with end-of-life disposal. In contrast, metal EOATs require energy-intensive recycling processes and often lead to higher material loss during recovery.

Industry-Specific Application Suitability

Thermoplastic EOATs offer exceptional chemical resistance and flexibility, making them ideal for pharmaceutical and food processing industries where hygiene and contamination prevention are critical. Metal EOATs provide superior strength and durability, preferred in automotive and heavy manufacturing sectors requiring high-load handling and precise machining. Selecting EOAT materials depends on industry-specific demands for corrosion resistance, weight constraints, and mechanical performance.

Future Trends in EOAT Material Selection

Thermoplastic EOAT materials are gaining traction due to their lightweight nature, design flexibility, and recyclability, aligning with sustainable manufacturing trends. Metal EOAT remains essential for high-strength, high-temperature applications but faces challenges in cost and weight. Your choice of EOAT material will increasingly depend on balancing performance requirements with environmental impact, as industry demand shifts towards eco-friendly and adaptive automation solutions.

Thermoplastic EOAT vs Metal EOAT Infographic

libmatt.com

libmatt.com