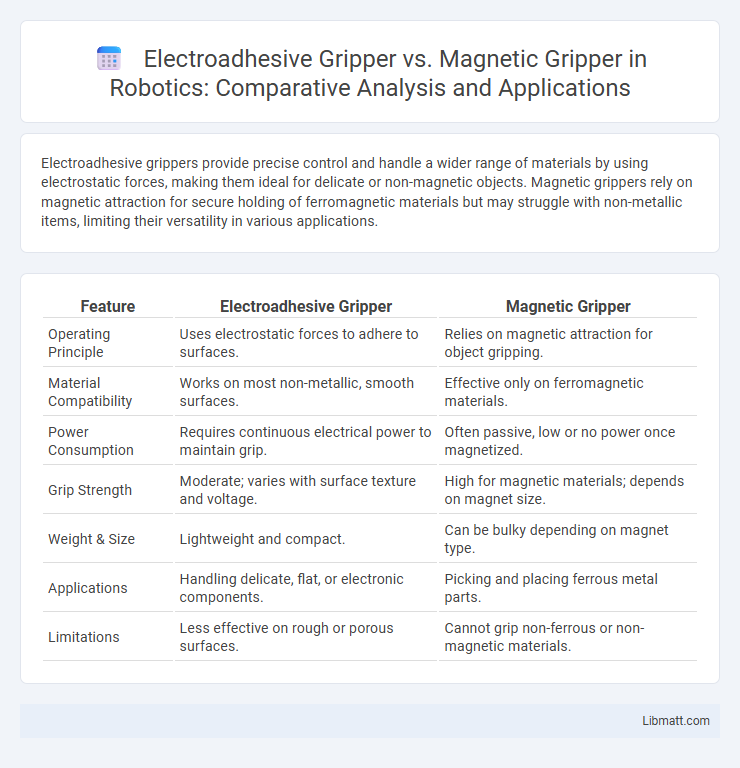

Electroadhesive grippers provide precise control and handle a wider range of materials by using electrostatic forces, making them ideal for delicate or non-magnetic objects. Magnetic grippers rely on magnetic attraction for secure holding of ferromagnetic materials but may struggle with non-metallic items, limiting their versatility in various applications.

Table of Comparison

| Feature | Electroadhesive Gripper | Magnetic Gripper |

|---|---|---|

| Operating Principle | Uses electrostatic forces to adhere to surfaces. | Relies on magnetic attraction for object gripping. |

| Material Compatibility | Works on most non-metallic, smooth surfaces. | Effective only on ferromagnetic materials. |

| Power Consumption | Requires continuous electrical power to maintain grip. | Often passive, low or no power once magnetized. |

| Grip Strength | Moderate; varies with surface texture and voltage. | High for magnetic materials; depends on magnet size. |

| Weight & Size | Lightweight and compact. | Can be bulky depending on magnet type. |

| Applications | Handling delicate, flat, or electronic components. | Picking and placing ferrous metal parts. |

| Limitations | Less effective on rough or porous surfaces. | Cannot grip non-ferrous or non-magnetic materials. |

Introduction to Electroadhesive and Magnetic Grippers

Electroadhesive grippers utilize electrostatic forces to adhere to a variety of surfaces, enabling precise handling of delicate or irregular objects without causing damage. Magnetic grippers, on the other hand, rely on magnetic fields to pick up ferromagnetic materials, offering strong holding force and efficiency in industrial automation environments. Your choice between these gripper types depends on the material compatibility and the specific application requirements of your robotic system.

How Electroadhesive Grippers Work

Electroadhesive grippers operate by applying an electric voltage to create an electrostatic field that generates attractive forces between the gripper and the object's surface. This process enables precise gripping of a wide range of materials, including non-metallic and delicate items, without causing damage. Your choice of electroadhesive technology offers advantages in versatility and energy efficiency compared to magnetic grippers, which rely solely on magnetism and are limited to ferromagnetic objects.

How Magnetic Grippers Work

Magnetic grippers operate by generating a magnetic field that attracts and holds ferromagnetic materials, utilizing either permanent magnets or electromagnets to create the necessary holding force. Electromagnetic grippers can be turned on or off by controlling the electric current, providing precise gripping control, while permanent magnetic grippers rely on the inherent magnetic field without power consumption. Compared to electroadhesive grippers, magnetic grippers offer strong holding capabilities for metallic objects but are limited to ferrous materials.

Key Differences Between Electroadhesive and Magnetic Grippers

Electroadhesive grippers use electrostatic forces to adhere to a wide range of materials, offering precise control and compatibility with non-ferrous and delicate objects, while magnetic grippers rely on magnetic fields, limiting their use to ferromagnetic materials only. Electroadhesive technology provides lower power consumption and minimal residual magnetism, making it ideal for electronics handling, whereas magnetic grippers deliver higher gripping force and faster response times for heavy-duty applications. The key differences lie in material compatibility, energy efficiency, and application flexibility, with electroadhesive grippers excelling in versatility and magnetic grippers excelling in strength.

Material Compatibility: What Can Each Gripper Handle?

Electroadhesive grippers excel in handling a wide range of materials, including non-metallic and delicate surfaces like glass, plastic, and thin films, due to their ability to generate adhesion through electrostatic forces without mechanical pressure. Magnetic grippers are limited to ferromagnetic materials such as iron, steel, and some alloys, making them unsuitable for non-metallic or non-magnetic items. Choosing between these grippers depends on your specific material requirements and the nature of the objects you need to manipulate.

Energy Efficiency Comparison

Electroadhesive grippers consume significantly less power by relying on induced electrostatic forces that activate only during gripping, resulting in minimal energy use when idle. Magnetic grippers require continuous current to maintain a magnetic field, leading to higher energy consumption especially during prolonged holding periods. This difference makes electroadhesive grippers more energy-efficient for applications demanding frequent pick-and-place operations with intermittent gripping.

Safety and Reliability Concerns

Electroadhesive grippers offer high precision and minimal electromagnetic interference, enhancing safety in delicate handling applications, while magnetic grippers provide robust holding force but may pose risks around sensitive electronic components due to stray magnetic fields. The reliability of electroadhesive grippers depends on stable voltage control and surface cleanliness, whereas magnetic grippers are generally more consistent in varying environmental conditions but can degrade with metal contamination. Your choice between these gripping technologies should balance the need for safe operation around electronics and the consistency of grip strength under different industrial environments.

Application Areas: Where Are They Used?

Electroadhesive grippers are widely utilized in delicate electronics assembly, flexible manufacturing systems, and handling flexible materials like thin films and textiles due to their gentle yet firm adhesion without requiring magnetic properties. Magnetic grippers excel in industrial automation for manipulating ferromagnetic materials such as steel sheets, automotive parts, and heavy metal components, providing strong, reliable holding power. Both gripper types serve crucial roles in robotics, but electroadhesive systems dominate non-metallic object handling, while magnetic grippers are preferred in metal-focused applications.

Cost Analysis and Maintenance Requirements

Electroadhesive grippers generally have higher upfront costs due to advanced materials and electronic components but offer low energy consumption, reducing operational expenses. Magnetic grippers typically cost less initially and require minimal maintenance, as they rely on passive magnetic forces without electronic parts. Maintenance for electroadhesive grippers involves periodic inspection of electrodes and insulation, while magnetic grippers mainly need checks for wear or damage to magnets and mechanical components.

Choosing the Right Gripper for Your Needs

Electroadhesive grippers provide precise control and gentle handling for delicate or irregular objects using electrostatic forces, making them ideal for electronics and flexible materials. Magnetic grippers excel in securely gripping ferromagnetic materials with strong, reliable attraction, suitable for heavy-duty applications like metal fabrication. Your choice depends on material compatibility, load capacity, and handling sensitivity to optimize performance and efficiency in your automation processes.

Electroadhesive Gripper vs Magnetic Gripper Infographic

libmatt.com

libmatt.com