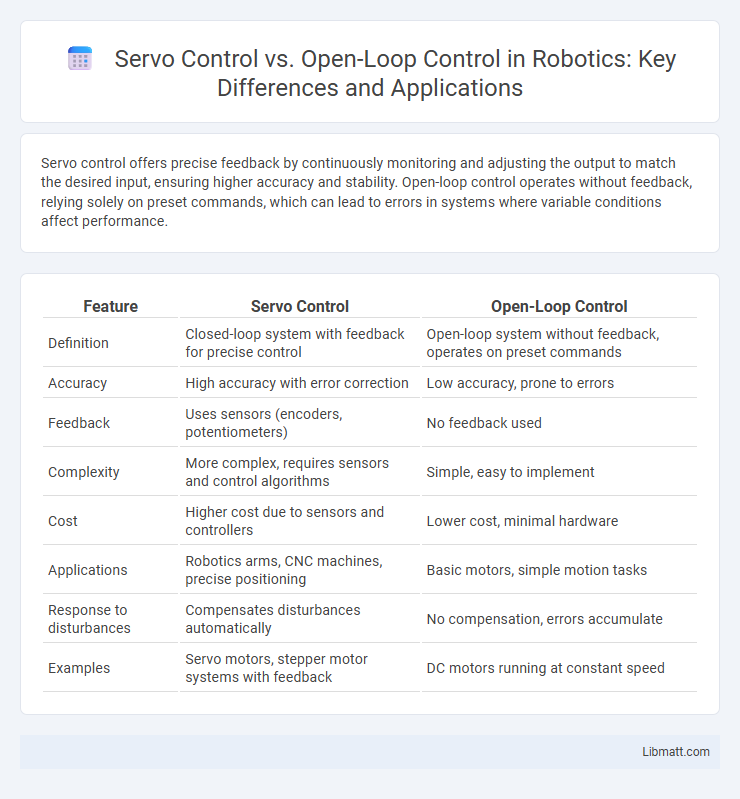

Servo control offers precise feedback by continuously monitoring and adjusting the output to match the desired input, ensuring higher accuracy and stability. Open-loop control operates without feedback, relying solely on preset commands, which can lead to errors in systems where variable conditions affect performance.

Table of Comparison

| Feature | Servo Control | Open-Loop Control |

|---|---|---|

| Definition | Closed-loop system with feedback for precise control | Open-loop system without feedback, operates on preset commands |

| Accuracy | High accuracy with error correction | Low accuracy, prone to errors |

| Feedback | Uses sensors (encoders, potentiometers) | No feedback used |

| Complexity | More complex, requires sensors and control algorithms | Simple, easy to implement |

| Cost | Higher cost due to sensors and controllers | Lower cost, minimal hardware |

| Applications | Robotics arms, CNC machines, precise positioning | Basic motors, simple motion tasks |

| Response to disturbances | Compensates disturbances automatically | No compensation, errors accumulate |

| Examples | Servo motors, stepper motor systems with feedback | DC motors running at constant speed |

Introduction to Servo Control and Open-Loop Control

Servo control uses feedback mechanisms to continuously monitor and adjust the system's output, ensuring precise and accurate performance in applications like robotics and CNC machines. Open-loop control operates without feedback, relying solely on predetermined inputs, which can lead to errors in dynamic or unpredictable environments. Your system's accuracy and adaptability depend significantly on choosing between these control methods based on the specific application requirements.

Fundamentals of Open-Loop Control Systems

Open-loop control systems operate without feedback, issuing commands based solely on predefined input signals, which limits accuracy in unpredictable environments. These systems rely on precise calibration and consistent conditions to function effectively, as they cannot correct errors or adjust output in real time. Common applications include simple devices like washing machines and basic timers where output predictability does not require dynamic adjustment.

Core Principles of Servo Control Systems

Servo control systems operate on feedback loops that continuously monitor and adjust the output to match the desired input, ensuring precise and accurate motion. Sensors detect position, velocity, or torque, providing real-time data to the controller, which dynamically corrects errors in the system. Your application benefits from enhanced stability and responsiveness, particularly in environments requiring high accuracy and adaptability.

Key Differences Between Servo and Open-Loop Control

Servo control systems use feedback mechanisms to continuously monitor and adjust the output, ensuring precise positioning and speed, while open-loop control operates without feedback, relying solely on input commands. The accuracy of servo control makes it ideal for applications requiring high precision, such as robotics and CNC machines, whereas open-loop control suits simpler tasks with predictable conditions, like basic timers or fans. Servo systems are typically more complex and costly due to sensors and controllers, contrasting with the straightforward, inexpensive nature of open-loop designs.

Performance Comparison: Accuracy and Precision

Servo control systems offer superior accuracy and precision compared to open-loop control by continuously monitoring feedback and adjusting actuator movements to minimize errors. Open-loop control lacks real-time feedback, resulting in lower precision and potential deviations from desired performance. Your application benefits from servo control when exact positioning and consistent performance are critical.

Response to Disturbances and Feedback Mechanisms

Servo control systems continuously monitor feedback from sensors to adjust output and correct deviations caused by disturbances, ensuring precise and stable operation. Open-loop control lacks feedback mechanisms, so it cannot automatically adjust to disturbances, resulting in potential errors and reduced accuracy. Your choice of control method directly impacts the system's ability to maintain performance under varying conditions.

Applications Best Suited for Open-Loop Control

Open-loop control systems are best suited for applications where the process is simple, the output is predictable, and real-time feedback is unnecessary, such as in household appliances like washing machines or simple conveyor belts. These systems operate efficiently in environments with minimal disturbances and consistent input conditions, reducing system complexity and cost. Your choice of control strategy should consider the stability and precision requirements to ensure optimal performance.

Industries and Use-Cases for Servo Control

Servo control systems are extensively used in industries requiring precise position, speed, and torque control, such as robotics, CNC machinery, aerospace, and automated manufacturing. These systems enable Your equipment to achieve high accuracy in applications like robotic arms, conveyor belts, and precision assembly lines, where feedback loops continuously adjust performance. Compared to open-loop control, servo control enhances efficiency and reliability by correcting errors in real-time, making it ideal for complex and dynamic industrial environments.

Pros and Cons of Each Control Method

Servo control offers precise positioning and high accuracy by continuously monitoring feedback, making it ideal for applications requiring strict control, though it involves higher cost and complexity due to sensors and closed-loop architecture. Open-loop control is simpler and less expensive, suitable for applications where exact positioning is not critical, but it lacks the ability to correct errors or disturbances, resulting in potential inaccuracies. The choice depends on the necessary precision, system complexity, and budget constraints, with servo control favored for high-performance environments and open-loop control preferred for straightforward tasks.

Choosing the Right Control System for Your Needs

Servo control offers precise feedback and position accuracy, making it ideal for applications requiring exact motion and speed regulation. Open-loop control is simpler and cost-effective, suitable for systems where output predictability and consistency are not critical. Your choice depends on the need for precision versus budget constraints and system complexity.

Servo control vs Open-loop control Infographic

libmatt.com

libmatt.com