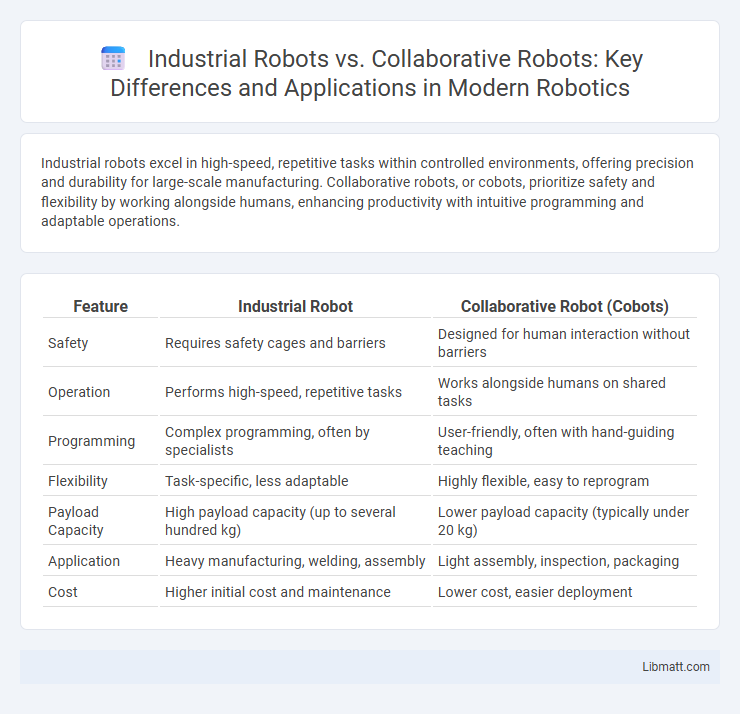

Industrial robots excel in high-speed, repetitive tasks within controlled environments, offering precision and durability for large-scale manufacturing. Collaborative robots, or cobots, prioritize safety and flexibility by working alongside humans, enhancing productivity with intuitive programming and adaptable operations.

Table of Comparison

| Feature | Industrial Robot | Collaborative Robot (Cobots) |

|---|---|---|

| Safety | Requires safety cages and barriers | Designed for human interaction without barriers |

| Operation | Performs high-speed, repetitive tasks | Works alongside humans on shared tasks |

| Programming | Complex programming, often by specialists | User-friendly, often with hand-guiding teaching |

| Flexibility | Task-specific, less adaptable | Highly flexible, easy to reprogram |

| Payload Capacity | High payload capacity (up to several hundred kg) | Lower payload capacity (typically under 20 kg) |

| Application | Heavy manufacturing, welding, assembly | Light assembly, inspection, packaging |

| Cost | Higher initial cost and maintenance | Lower cost, easier deployment |

Introduction to Industrial and Collaborative Robots

Industrial robots are automated machines designed for high-speed, precise, and repetitive tasks in manufacturing environments, typically operating in isolated workcells to ensure safety. Collaborative robots, or cobots, are engineered to work safely alongside human operators, featuring advanced sensors and flexible programming for tasks requiring adaptability and human interaction. Both types optimize production efficiency but differ significantly in application scope, safety requirements, and integration within industrial workflows.

Defining Industrial Robots

Industrial robots are programmable machines designed for high-speed, high-precision tasks in manufacturing environments, capable of operating autonomously or with minimal human intervention. They typically perform repetitive functions such as welding, painting, assembly, and material handling within enclosed safety zones to prevent human contact. These robots feature high payload capacities, fast cycle times, and robust construction suited for heavy-duty applications in automotive, electronics, and metal fabrication industries.

Understanding Collaborative Robots

Collaborative robots, or cobots, are designed to work safely alongside humans without the need for extensive safety barriers typically required by traditional industrial robots. These robots use advanced sensors and software to detect human presence, enabling seamless interaction and enhancing productivity in shared workspaces. Understanding the capabilities of cobots can help you integrate automation that improves efficiency while maintaining workplace safety.

Key Differences Between Industrial and Collaborative Robots

Industrial robots operate independently in structured environments, designed for high-speed, repetitive tasks requiring precision and strength, often enclosed for safety. Collaborative robots, or cobots, work alongside humans with built-in sensors and safety features to enable direct interaction without protective barriers. Your choice depends on the application's need for flexibility, safety standards, and task complexity.

Safety Features: Traditional vs Collaborative Approaches

Industrial robots rely heavily on physical barriers, safety cages, and emergency stop mechanisms to protect operators from high-speed, high-force movements. Collaborative robots, or cobots, integrate advanced sensors, force-limited joints, and real-time monitoring to detect human presence and reduce injury risk during shared tasks. You benefit from enhanced workplace safety with cobots, enabling closer human-robot interaction without extensive protective infrastructure.

Programming and Ease of Operation

Industrial robots require complex programming using specialized languages and often need skilled engineers for setup and operation, limiting accessibility for non-experts. Collaborative robots feature intuitive programming interfaces, including hand-guiding and graphical user interfaces, enabling fast deployment and ease of use even by operators without extensive technical knowledge. The simplicity of collaborative robot programming significantly reduces downtime and facilitates seamless integration into dynamic manufacturing environments.

Applications in Manufacturing Environments

Industrial robots excel in heavy-duty, high-speed applications such as welding, painting, and assembly lines, where precision and repetitive tasks are essential. Collaborative robots (cobots) are designed for close interaction with human workers, making them ideal for small batch production, quality inspection, and tasks requiring flexibility or adaptability. Your manufacturing environment benefits from industrial robots for large-scale operations, while cobots enhance safety and efficiency in mixed human-machine workspaces.

Cost Considerations and Return on Investment

Industrial robots generally require a higher initial investment due to their complex programming, heavy-duty construction, and integration costs, whereas collaborative robots (cobots) feature lower upfront expenses and flexible deployment with minimal infrastructure changes. The return on investment (ROI) for industrial robots is often realized through high-volume, consistent production benefiting from speed and precision, while cobots offer cost savings and faster ROI by enhancing human labor efficiency and reducing downtime in small to medium-sized batch processes. Companies must evaluate total cost of ownership, including maintenance, training, and safety measures, to determine the optimal balance between automation scale and financial returns.

Future Trends in Robotics: Industrial vs Collaborative

Future trends in robotics emphasize increased integration of AI and machine learning, enhancing both industrial and collaborative robots' capabilities in precision and adaptability. Industrial robots are evolving with improved speed, payload capacity, and autonomous decision-making for complex manufacturing tasks. Collaborative robots, or cobots, focus on advanced safety features, ease of programming, and seamless human-robot interaction, enabling your workforce to work alongside robots efficiently and safely.

Choosing the Right Robot for Your Business Needs

Choosing the right robot depends on your business's production requirements, safety standards, and workspace configuration. Industrial robots excel in high-speed, repetitive tasks within fenced environments, delivering precision and durability for large-scale manufacturing. Collaborative robots offer flexibility, easy programming, and safe human interaction, ideal for small to medium enterprises aiming to enhance productivity without extensive safety barriers.

Industrial robot vs Collaborative robot Infographic

libmatt.com

libmatt.com