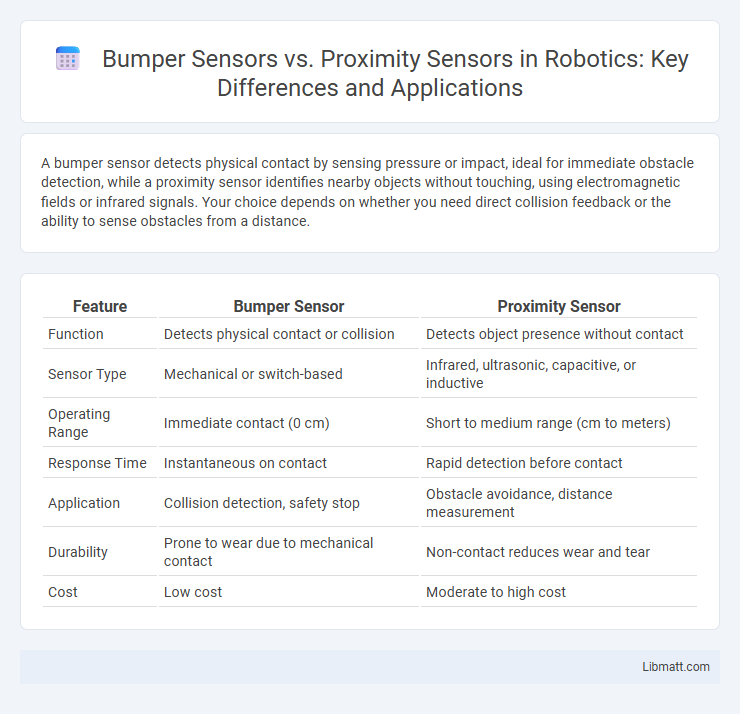

A bumper sensor detects physical contact by sensing pressure or impact, ideal for immediate obstacle detection, while a proximity sensor identifies nearby objects without touching, using electromagnetic fields or infrared signals. Your choice depends on whether you need direct collision feedback or the ability to sense obstacles from a distance.

Table of Comparison

| Feature | Bumper Sensor | Proximity Sensor |

|---|---|---|

| Function | Detects physical contact or collision | Detects object presence without contact |

| Sensor Type | Mechanical or switch-based | Infrared, ultrasonic, capacitive, or inductive |

| Operating Range | Immediate contact (0 cm) | Short to medium range (cm to meters) |

| Response Time | Instantaneous on contact | Rapid detection before contact |

| Application | Collision detection, safety stop | Obstacle avoidance, distance measurement |

| Durability | Prone to wear due to mechanical contact | Non-contact reduces wear and tear |

| Cost | Low cost | Moderate to high cost |

Introduction to Bumper and Proximity Sensors

Bumper sensors detect direct physical contact by triggering a switch or sensor when an object presses against the bumper, offering simple collision detection. Proximity sensors utilize electromagnetic fields or light to sense objects at a distance, enabling non-contact detection for navigation and obstacle avoidance. Both sensor types are integral to robotics and automotive applications, with bumper sensors providing immediate feedback and proximity sensors allowing advanced spatial awareness.

How Bumper Sensors Work

Bumper sensors operate through physical contact, triggering a switch or sensor when an object presses against the bumper surface, causing the system to register an obstacle. They rely on mechanical or pressure-activated components that detect collisions or impacts to halt or alter a robot's movement. Unlike proximity sensors that use electromagnetic fields or light to detect objects at a distance, bumper sensors require direct contact to initiate a response.

How Proximity Sensors Operate

Proximity sensors operate by detecting objects without physical contact, using electromagnetic fields, light, or sound waves to measure the presence or distance of nearby items. Common types include inductive sensors for metal detection, capacitive sensors for various materials, and ultrasonic sensors that emit sound waves to calculate the return time from objects. These sensors provide precise, real-time data crucial for automation, robotics, and safety systems in industrial applications.

Key Differences Between Bumper and Proximity Sensors

Bumper sensors detect physical contact through mechanical activation when an object is touched, triggering an immediate stop or response, while proximity sensors use electromagnetic fields or ultrasonic waves to sense objects without contact. Your choice depends on whether you need tactile feedback or early obstacle detection; bumper sensors prioritize direct impact detection, whereas proximity sensors enable non-contact awareness and smoother navigation. Proximity sensors typically offer adjustable sensing ranges and can detect multiple object types, making them ideal for dynamic environments.

Advantages of Bumper Sensors

Bumper sensors provide reliable physical impact detection, ensuring precise and immediate response upon contact with obstacles, which enhances safety in robotics and automation systems. They require minimal calibration and are highly durable in harsh environments, maintaining consistent performance without complex electronic interference. Your choice of a bumper sensor guarantees straightforward installation and cost-effective maintenance compared to proximity sensors, making them ideal for robust, collision-sensitive applications.

Advantages of Proximity Sensors

Proximity sensors offer non-contact detection, reducing wear and maintenance compared to bumper sensors that rely on physical impact. These sensors provide faster response times and higher precision, enhancing automation and safety in applications like robotics and industrial machinery. Your systems benefit from increased durability and reliability due to the absence of mechanical components in proximity sensors.

Common Applications in Robotics and Automation

Bumper sensors are widely used in robotics for collision detection, enabling robots to physically sense obstacles in environments like warehouse automation and mobile robots. Proximity sensors excel in non-contact object detection, making them ideal for applications such as automated assembly lines, material handling, and obstacle avoidance systems. Your choice between these sensors depends on the need for contact-based feedback versus distance measurement in various automation tasks.

Limitations and Challenges

Bumper sensors, while reliable for direct physical contact detection, face limitations in sensing objects without impact, posing risks in high-speed or delicate environments. Proximity sensors provide non-contact detection but can struggle with materials that absorb or reflect signals unevenly, leading to false positives or missed objects. Your choice must account for environmental conditions and application-specific challenges to optimize sensor performance and safety.

Choosing the Right Sensor for Your Needs

Choosing the right sensor depends on your specific application requirements; bumper sensors provide physical contact detection suitable for impact-sensitive environments, while proximity sensors offer non-contact detection with varying ranges and sensing technologies like infrared or ultrasonic. Proximity sensors excel in detecting objects before contact, preventing damage and enhancing automation precision, whereas bumper sensors are reliable for immediate collision alerts in tight spaces or safety-critical functions. Assess your environment, required detection range, and whether contact detection or early object sensing is more beneficial to determine the optimal sensor for your needs.

Future Trends in Sensor Technology

Future trends in sensor technology emphasize increased integration of bumper sensors and proximity sensors with AI-driven analytics for enhanced autonomous navigation and obstacle detection. Advancements in materials science are enabling sensors to become more compact, energy-efficient, and capable of multi-modal sensing, improving accuracy in diverse environmental conditions. Your systems will benefit from seamless connectivity and predictive maintenance features powered by IoT, ensuring smarter, safer, and more reliable sensor performance in automotive and industrial applications.

Bumper Sensor vs Proximity Sensor Infographic

libmatt.com

libmatt.com