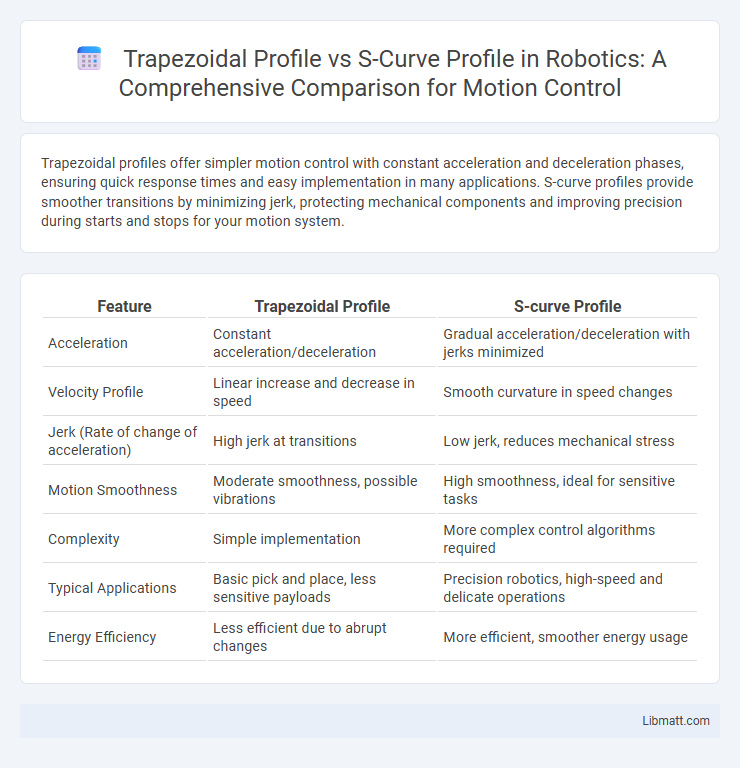

Trapezoidal profiles offer simpler motion control with constant acceleration and deceleration phases, ensuring quick response times and easy implementation in many applications. S-curve profiles provide smoother transitions by minimizing jerk, protecting mechanical components and improving precision during starts and stops for your motion system.

Table of Comparison

| Feature | Trapezoidal Profile | S-curve Profile |

|---|---|---|

| Acceleration | Constant acceleration/deceleration | Gradual acceleration/deceleration with jerks minimized |

| Velocity Profile | Linear increase and decrease in speed | Smooth curvature in speed changes |

| Jerk (Rate of change of acceleration) | High jerk at transitions | Low jerk, reduces mechanical stress |

| Motion Smoothness | Moderate smoothness, possible vibrations | High smoothness, ideal for sensitive tasks |

| Complexity | Simple implementation | More complex control algorithms required |

| Typical Applications | Basic pick and place, less sensitive payloads | Precision robotics, high-speed and delicate operations |

| Energy Efficiency | Less efficient due to abrupt changes | More efficient, smoother energy usage |

Introduction to Motion Profiles

Trapezoidal and S-curve profiles are fundamental motion profiles used in CNC machining and robotics to control acceleration and velocity. The trapezoidal profile features constant acceleration, constant velocity, and constant deceleration phases, resulting in sharp transitions that can induce mechanical stress. The S-curve profile smooths these transitions with gradual acceleration changes, reducing vibration and enhancing precision in high-speed motion control applications.

Understanding Trapezoidal Profile

Trapezoidal profile motion involves linear acceleration to a constant velocity followed by linear deceleration, forming a trapezoid shape on the velocity-time graph. This method is widely used in motion control systems for its simplicity and predictability, especially in industrial automation and robotics. Understanding the characteristics of trapezoidal profiles is essential for optimizing system performance, minimizing mechanical stress, and achieving precise positioning.

Overview of S-curve Profile

The S-curve profile features smooth acceleration and deceleration phases, reducing mechanical stress and vibration in motion control systems compared to the abrupt changes in velocity typical of trapezoidal profiles. This profile utilizes a continuous jerk control, enhancing precision and extending the lifespan of components in CNC machines, robotics, and automation equipment. By optimizing motion dynamics, S-curve profiles achieve superior performance in applications requiring high accuracy and smooth transitions.

Key Differences Between Trapezoidal and S-curve Profiles

Trapezoidal profiles feature constant acceleration and deceleration phases with abrupt transitions, resulting in simpler motion but higher mechanical stress. S-curve profiles use smooth, continuous jerk changes to minimize vibrations and provide a gentler motion, ideal for precise and delicate applications. Key differences include the trapezoidal profile's efficiency and simplicity versus the S-curve's superior smoothness and reduced wear on mechanical components.

Performance Comparison: Speed, Smoothness, and Accuracy

Trapezoidal profiles deliver faster acceleration and deceleration phases, enabling higher peak speeds but may cause abrupt changes in motion, affecting smoothness. S-curve profiles provide smoother transitions in velocity by gradually changing acceleration, enhancing motion fluidity and improving accuracy in precision tasks. Your choice depends on prioritizing maximum speed with trapezoidal profiles or superior smoothness and positional accuracy with S-curve motion control.

Applications Best Suited for Trapezoidal Profile

Trapezoidal profiles are best suited for applications requiring precise velocity control with straightforward acceleration and deceleration phases, such as CNC machining and basic robotic arm movements. They perform efficiently in systems where abrupt starts and stops are acceptable and rapid positioning is prioritized over smooth transitions. Industrial automation tasks with repetitive, linear motion patterns benefit significantly from the simplicity and predictability of trapezoidal velocity profiles.

Applications Best Suited for S-curve Profile

S-curve profiles excel in applications requiring smooth acceleration and deceleration to minimize mechanical stress and vibration, such as precision CNC machining, 3D printing, and robotic arms handling delicate components. Their gradual velocity transitions reduce inertia-induced backlash and improve motion control accuracy, making them ideal for high-precision manufacturing and automated assembly processes. Industries focused on quality and longevity of equipment benefit greatly from implementing S-curve motion profiles.

Pros and Cons of Trapezoidal Profile

Trapezoidal profiles offer simple implementation and predictable acceleration patterns, making them suitable for basic motion control tasks. Their main drawback is the abrupt transitions in acceleration, which can cause mechanical stress and vibrations in precision machinery. This profile is less effective in applications requiring smooth motion and minimal jerk compared to S-curve profiles.

Pros and Cons of S-curve Profile

The S-curve profile offers smoother acceleration and deceleration compared to the trapezoidal profile, reducing mechanical stress and vibration in motion systems. Its pros include improved performance in applications requiring high precision and reduced wear on components, enhancing system longevity. However, the S-curve profile can be more complex to implement and may require more computational resources, potentially increasing design and control system costs.

Choosing the Right Motion Profile for Your Application

Choosing the right motion profile depends on the specific requirements of your application, such as speed, acceleration, and load dynamics. Trapezoidal profiles excel in applications demanding straightforward control with constant acceleration and deceleration phases, ideal for systems with limited mechanical stress. S-curve profiles are preferred for high-precision tasks requiring smooth jerk transitions to minimize vibrations and extend component life, particularly in robotics and CNC machining.

Trapezoidal Profile vs S-curve Profile Infographic

libmatt.com

libmatt.com