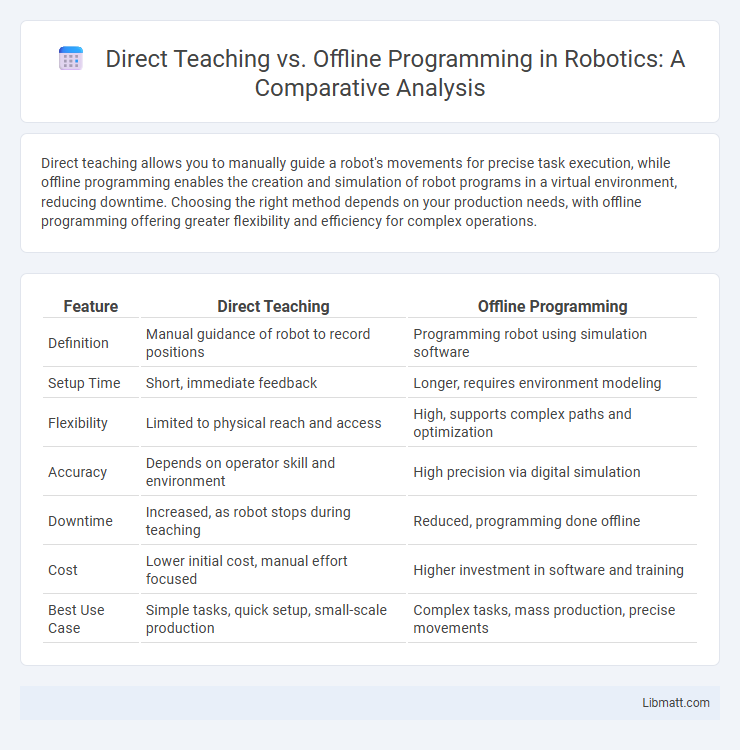

Direct teaching allows you to manually guide a robot's movements for precise task execution, while offline programming enables the creation and simulation of robot programs in a virtual environment, reducing downtime. Choosing the right method depends on your production needs, with offline programming offering greater flexibility and efficiency for complex operations.

Table of Comparison

| Feature | Direct Teaching | Offline Programming |

|---|---|---|

| Definition | Manual guidance of robot to record positions | Programming robot using simulation software |

| Setup Time | Short, immediate feedback | Longer, requires environment modeling |

| Flexibility | Limited to physical reach and access | High, supports complex paths and optimization |

| Accuracy | Depends on operator skill and environment | High precision via digital simulation |

| Downtime | Increased, as robot stops during teaching | Reduced, programming done offline |

| Cost | Lower initial cost, manual effort focused | Higher investment in software and training |

| Best Use Case | Simple tasks, quick setup, small-scale production | Complex tasks, mass production, precise movements |

Introduction to Direct Teaching and Offline Programming

Direct teaching involves guiding robots through physical movements, capturing real-time actions to program tasks intuitively. Offline programming uses computer software to create and simulate robot programs without halting production, enabling precise task planning and optimization. Both methods enhance automation efficiency but differ in approach, with direct teaching emphasizing hands-on interaction and offline programming focusing on virtual environment preparation.

Key Differences Between Direct Teaching and Offline Programming

Direct teaching involves manually guiding a robot through a series of motions to program its tasks, while offline programming uses computer software to create and simulate robot programs without halting production. Key differences include real-time interaction in direct teaching versus pre-simulation in offline programming, and the dependency on physical robot presence contrasted with software-based program development. Offline programming enhances efficiency by enabling program creation and testing before deployment, reducing machine downtime compared to direct teaching.

Advantages of Direct Teaching in Robotics

Direct Teaching in robotics offers precise and intuitive programming by allowing operators to physically guide the robot through tasks, reducing the complexity of coding and speeding up deployment. This method enhances accuracy in repetitive or intricate movements, ensuring consistent performance and lowering error rates during production. Your efficiency improves as direct teaching shortens setup times and simplifies adjustments, making it ideal for customized or small batch manufacturing.

Benefits of Offline Programming Methods

Offline programming methods offer significant benefits including enhanced safety by allowing robot programs to be developed without halting production lines or exposing operators to risks. These methods improve efficiency through simulation and error detection before deployment, minimizing downtime and costly mistakes. You can optimize complex tasks and customize robotic workflows with greater precision using offline programming tools.

Limitations of Direct Teaching Approaches

Direct teaching in robotics often faces limitations such as low precision due to manual guidance and difficulty in capturing complex trajectories or fine motions. It typically struggles with scalability since each new task requires repeated manual programming, leading to inefficiencies in production environments. Furthermore, direct teaching lacks flexibility in adapting to dynamic changes or variations in the manufacturing process compared to offline programming techniques.

Challenges Associated with Offline Programming

Offline programming faces challenges such as limited accuracy due to discrepancies between virtual simulation and real-world environments, leading to potential errors during robot operation. The complexity of creating precise 3D models demands significant time and expertise, making it difficult to handle intricate tasks or dynamic workspaces. Additionally, troubleshooting and fine-tuning programs often require multiple iterations, increasing downtime and reducing overall efficiency.

Applications Suitable for Direct Teaching

Direct teaching is ideal for programming robotic arms used in assembly lines, welding, and packaging, where precise, repeatable motions are crucial. It excels in environments requiring rapid setup and modifications without extensive coding knowledge, facilitating quick adaptation to unique product geometries. Complex paths and intricate operations in automotive manufacturing and electronics assembly benefit from direct teaching methods, enhancing accuracy and reducing programming time.

Industries Leveraging Offline Programming

Industries leveraging offline programming include automotive manufacturing, aerospace, and electronics, where precision and efficiency in robot path planning are critical. Offline programming enables the creation, simulation, and optimization of robot programs without halting production lines, significantly reducing downtime and improving workflow. This approach is essential for complex tasks such as welding, painting, and assembly in highly automated industrial environments.

Choosing the Right Approach: Factors to Consider

Choosing between Direct Teaching and Offline Programming depends on your project's complexity, required precision, and time constraints. Direct Teaching is ideal for simple, repetitive tasks needing quick setup, while Offline Programming excels in complex applications demanding detailed simulation and optimization. Evaluating factors such as ease of use, programming environment, and robot availability helps determine the optimal approach.

Future Trends in Robot Programming Techniques

Future trends in robot programming techniques emphasize the integration of artificial intelligence and machine learning to enhance direct teaching by enabling robots to learn from minimal human input and adapt in real time. Offline programming continues to evolve with the adoption of digital twins and virtual reality environments, allowing engineers to simulate, optimize, and deploy complex robot tasks remotely with higher precision. Hybrid approaches combining direct teaching's intuitive guidance and offline programming's simulation capabilities are becoming prevalent, promoting seamless scalability and flexibility in industrial automation.

Direct Teaching vs Offline Programming Infographic

libmatt.com

libmatt.com