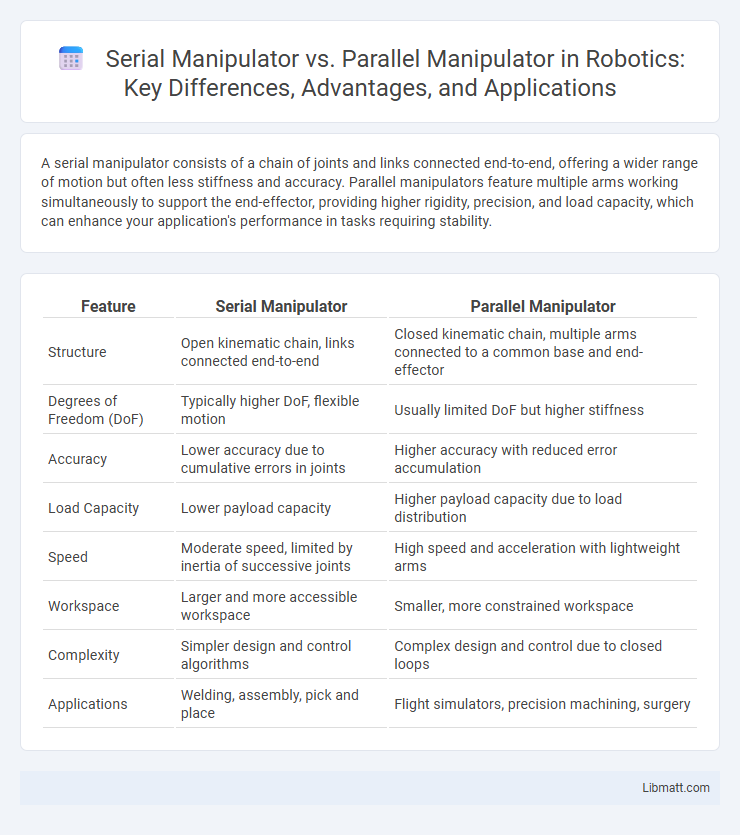

A serial manipulator consists of a chain of joints and links connected end-to-end, offering a wider range of motion but often less stiffness and accuracy. Parallel manipulators feature multiple arms working simultaneously to support the end-effector, providing higher rigidity, precision, and load capacity, which can enhance your application's performance in tasks requiring stability.

Table of Comparison

| Feature | Serial Manipulator | Parallel Manipulator |

|---|---|---|

| Structure | Open kinematic chain, links connected end-to-end | Closed kinematic chain, multiple arms connected to a common base and end-effector |

| Degrees of Freedom (DoF) | Typically higher DoF, flexible motion | Usually limited DoF but higher stiffness |

| Accuracy | Lower accuracy due to cumulative errors in joints | Higher accuracy with reduced error accumulation |

| Load Capacity | Lower payload capacity | Higher payload capacity due to load distribution |

| Speed | Moderate speed, limited by inertia of successive joints | High speed and acceleration with lightweight arms |

| Workspace | Larger and more accessible workspace | Smaller, more constrained workspace |

| Complexity | Simpler design and control algorithms | Complex design and control due to closed loops |

| Applications | Welding, assembly, pick and place | Flight simulators, precision machining, surgery |

Introduction to Manipulators

Serial manipulators consist of a sequence of joints and links arranged in a chain, enabling a wide range of motion and precision tasks in industries such as manufacturing and robotics. Parallel manipulators feature multiple arms connected to a single base and end-effector, providing increased stiffness, load-carrying capacity, and accuracy in applications like flight simulators and machining. Both types of manipulators are fundamental in automation, with design choices driven by specific operational requirements involving workspace, payload, and control complexity.

Defining Serial Manipulators

Serial manipulators consist of a sequence of joints and links arranged in a series, enabling end-effector movement through cumulative joint motions. These manipulators offer a large workspace and high flexibility but often face challenges in accuracy and load capacity due to the accumulation of errors along the chain. Common applications include robotic arms used in manufacturing, assembly, and material handling where precise positioning and reach are essential.

Understanding Parallel Manipulators

Parallel manipulators feature multiple kinematic chains connecting the base to the end-effector, offering high rigidity, precision, and load capacity compared to serial manipulators. These systems excel in applications requiring heavy payloads and enhanced stiffness, such as flight simulators and precision machining. Their closed-loop structure reduces error accumulation, resulting in superior accuracy and repeatability.

Structural Differences

Serial manipulators consist of a series of joints and links arranged end-to-end, allowing a wide range of motion and flexibility in positioning tasks. Parallel manipulators feature multiple kinematic chains connected simultaneously between the base and the end-effector, providing higher stiffness and load capacity. Structural differences influence precision, workspace, and mechanical complexity in robotic applications.

Kinematic Analysis

Serial manipulators feature a kinematic chain composed of sequentially connected joints and links, enabling straightforward forward and inverse kinematic analysis but often resulting in cumulative positioning errors and limited stiffness. Parallel manipulators have multiple kinematic chains connecting the base to the end-effector, which increases system rigidity and accuracy while making the kinematic analysis more complex due to closed-loop constraints. The workspace and singularity conditions differ significantly between these manipulators, with parallel manipulators offering higher precision at the cost of more challenging kinematic and dynamic modeling.

Motion and Workspace Comparison

Serial manipulators offer a larger and more versatile workspace with the ability to reach various positions by extending their linked joints in series, providing flexibility in motion. Parallel manipulators feature a more compact and rigid structure, delivering higher precision and stiffness but with a limited and often more complex workspace shape. Your choice depends on whether you prioritize extensive reach and maneuverability or superior accuracy and structural stability.

Payload Capacity and Rigidity

Parallel manipulators exhibit higher payload capacity and rigidity compared to serial manipulators due to their closed-loop kinematic chains distributing loads more evenly. Serial manipulators, with their open-chain design, experience cumulative deflections at each joint, resulting in lower overall stiffness and reduced capacity for heavy loads. The structural advantage of parallel manipulators makes them ideal for high-precision tasks requiring substantial force application and minimal deformation.

Accuracy and Repeatability

Parallel manipulators offer superior accuracy and repeatability due to their rigid closed-loop kinematic chains, which minimize deflections and improve stiffness. Serial manipulators tend to have lower accuracy and repeatability because of cumulative errors from multiple joints and links causing more compliance. The inherent structural design of parallel manipulators results in better load distribution and reduced error propagation, making them ideal for high-precision applications.

Applications in Industry

Serial manipulators are widely used in industries requiring precise and flexible motion, such as automotive assembly, welding, and packaging, due to their extensive reach and dexterity. Parallel manipulators excel in applications demanding high stiffness, accuracy, and load capacity, including flight simulators, CNC machining, and medical robotics. Your choice between the two depends on task-specific requirements like workspace size, speed, and precision.

Advantages and Limitations

Serial manipulators offer a large workspace and high dexterity, making them ideal for tasks requiring complex movements and reach. Limitations include lower stiffness and accuracy due to cumulative joint errors and reduced payload capacity. Parallel manipulators provide superior stiffness, high precision, and better load-bearing capabilities but have a limited workspace and more complex control algorithms, impacting your choice based on application needs.

Serial Manipulator vs Parallel Manipulator Infographic

libmatt.com

libmatt.com