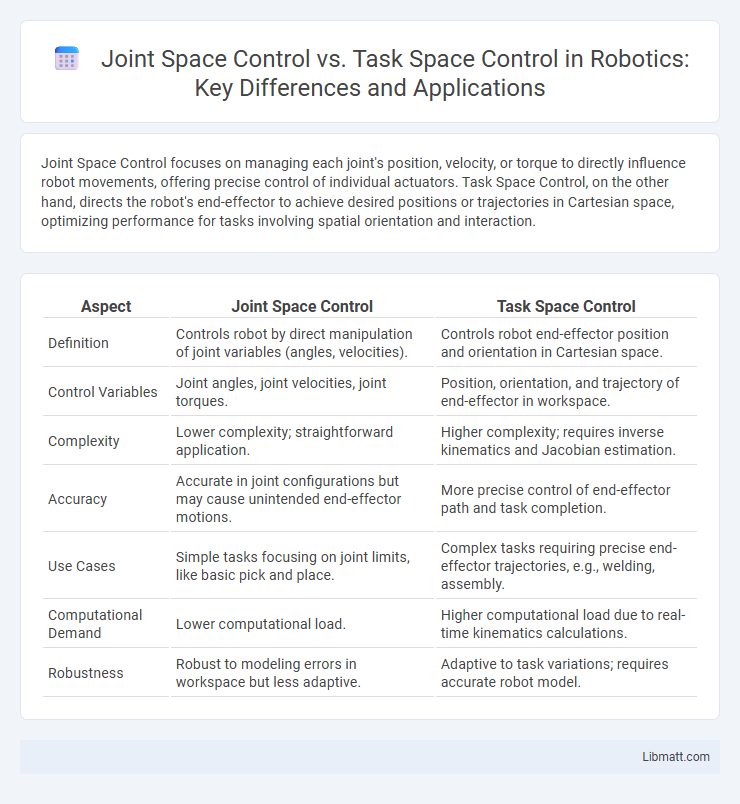

Joint Space Control focuses on managing each joint's position, velocity, or torque to directly influence robot movements, offering precise control of individual actuators. Task Space Control, on the other hand, directs the robot's end-effector to achieve desired positions or trajectories in Cartesian space, optimizing performance for tasks involving spatial orientation and interaction.

Table of Comparison

| Aspect | Joint Space Control | Task Space Control |

|---|---|---|

| Definition | Controls robot by direct manipulation of joint variables (angles, velocities). | Controls robot end-effector position and orientation in Cartesian space. |

| Control Variables | Joint angles, joint velocities, joint torques. | Position, orientation, and trajectory of end-effector in workspace. |

| Complexity | Lower complexity; straightforward application. | Higher complexity; requires inverse kinematics and Jacobian estimation. |

| Accuracy | Accurate in joint configurations but may cause unintended end-effector motions. | More precise control of end-effector path and task completion. |

| Use Cases | Simple tasks focusing on joint limits, like basic pick and place. | Complex tasks requiring precise end-effector trajectories, e.g., welding, assembly. |

| Computational Demand | Lower computational load. | Higher computational load due to real-time kinematics calculations. |

| Robustness | Robust to modeling errors in workspace but less adaptive. | Adaptive to task variations; requires accurate robot model. |

Introduction to Robotic Control Paradigms

Joint Space Control regulates a robot's movements by directly commanding joint angles or velocities, optimizing precision in individual joint actuation and simplifying inverse kinematics calculations. Task Space Control operates in the robot's operational space, focusing on controlling the position and orientation of the end-effector to achieve desired trajectories and manipulate objects effectively. Your choice between these paradigms depends on the specific application requirements, balancing control complexity, accuracy, and responsiveness in robotic systems.

Defining Joint Space Control

Joint Space Control refers to manipulating a robot or mechanical system by directly controlling the individual joint angles or positions, optimizing each joint's torque or velocity to achieve desired movements. This method leverages the robot's kinematic model to convert task commands into joint commands, ensuring precise control within the joint coordinate system. It contrasts with Task Space Control, which focuses on controlling the end-effector's position and orientation in Cartesian space rather than the joints themselves.

Understanding Task Space Control

Task Space Control focuses on managing the end-effector's position and orientation directly in Cartesian space, enhancing precision in performing specific tasks like grasping or welding. By controlling the robot's movement in task space rather than joint angles, it simplifies complex operations and improves interaction with the environment. Your robotic system benefits from this approach by achieving more intuitive and adaptable control, especially in dynamic or unstructured settings.

Key Differences Between Joint and Task Space Control

Joint space control focuses on managing the angles and velocities of individual robot joints, providing precise control over each actuator's position. Task space control, on the other hand, governs the end-effector's position and orientation in Cartesian coordinates, enabling more intuitive control for tasks involving spatial movement. Understanding these key differences allows you to select the appropriate control strategy based on whether your priority is direct joint manipulation or achieving specific end-effector goals in the workspace.

Advantages of Joint Space Strategies

Joint space control strategies offer precise manipulation of individual joint angles, enabling effective handling of kinematic constraints and singularities. They provide improved stability and simplified dynamic modeling by directly controlling actuator torques and positions, leading to enhanced robustness in robotic systems. This approach is particularly advantageous for complex robots with high degrees of freedom, facilitating accurate trajectory tracking and efficient collision avoidance.

Benefits of Task Space Approaches

Task space control offers precise manipulation of end-effectors by directly regulating their position and orientation in Cartesian coordinates, enhancing accuracy in complex tasks like robotic assembly or surgery. This approach simplifies handling multi-degree-of-freedom robots by reducing the computational complexity involved in coordinating joint movements. Improved adaptability to dynamic environments and obstacle avoidance are intrinsic benefits, enabling efficient real-time adjustments during task execution.

Common Applications of Each Control Method

Joint Space Control is commonly used in industrial robotics for precise manipulation tasks such as pick-and-place operations, welding, and assembly where controlling individual joint angles ensures high accuracy and repeatability. Task Space Control is preferred in applications requiring end-effector trajectory planning and obstacle avoidance, such as robotic surgery, humanoid robots, and mobile manipulators performing complex interactions in dynamic environments. Both methods serve critical roles in automation and robotics, with joint space control excelling in rigid task execution and task space control enabling adaptive, goal-oriented motion.

Challenges and Limitations of Joint Space Control

Joint space control faces challenges such as difficulty in directly managing end-effector trajectories and dealing with nonlinear robot dynamics. These control methods often struggle with complex environments where precise task execution requires handling constraints like obstacle avoidance and force interaction. Additionally, joint space control can lead to slow computational performance when converting between joint angles and task-oriented goals, limiting real-time applications.

Challenges and Limitations of Task Space Control

Task space control faces challenges in accurately mapping desired end-effector trajectories to joint angles, often resulting in computational complexity and sensitivity to modeling errors. The presence of kinematic singularities and limited workspace boundaries can restrict effective control and precision. Your control system may struggle with real-time adaptability due to these constraints, impacting performance in dynamic or uncertain environments.

Future Trends in Robotic Control Systems

Future trends in robotic control systems emphasize the integration of joint space control and task space control through hybrid approaches that enhance precision and adaptability. Advances in machine learning and sensor fusion are driving the development of controllers capable of real-time optimization for complex, uncertain environments. Increasing use of artificial intelligence and edge computing enables more autonomous and intelligent robotic systems capable of seamless transitions between joint-level commands and task-oriented goals.

Joint Space Control vs Task Space Control Infographic

libmatt.com

libmatt.com