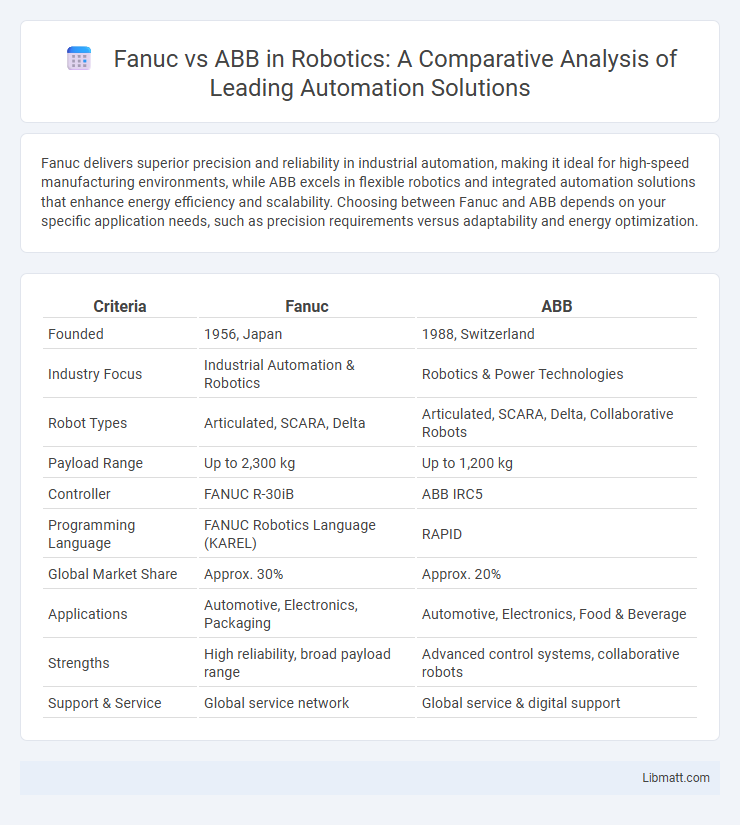

Fanuc delivers superior precision and reliability in industrial automation, making it ideal for high-speed manufacturing environments, while ABB excels in flexible robotics and integrated automation solutions that enhance energy efficiency and scalability. Choosing between Fanuc and ABB depends on your specific application needs, such as precision requirements versus adaptability and energy optimization.

Table of Comparison

| Criteria | Fanuc | ABB |

|---|---|---|

| Founded | 1956, Japan | 1988, Switzerland |

| Industry Focus | Industrial Automation & Robotics | Robotics & Power Technologies |

| Robot Types | Articulated, SCARA, Delta | Articulated, SCARA, Delta, Collaborative Robots |

| Payload Range | Up to 2,300 kg | Up to 1,200 kg |

| Controller | FANUC R-30iB | ABB IRC5 |

| Programming Language | FANUC Robotics Language (KAREL) | RAPID |

| Global Market Share | Approx. 30% | Approx. 20% |

| Applications | Automotive, Electronics, Packaging | Automotive, Electronics, Food & Beverage |

| Strengths | High reliability, broad payload range | Advanced control systems, collaborative robots |

| Support & Service | Global service network | Global service & digital support |

Introduction to Fanuc and ABB

Fanuc and ABB are leading companies in industrial automation and robotics, with Fanuc specializing in CNC systems and factory automation solutions, known for its precision and reliability. ABB offers a broad portfolio including robotics, electrification, and digital solutions targeting enhanced productivity and sustainability in manufacturing. Your choice between Fanuc and ABB depends on the specific automation needs and integration capabilities required for your production environment.

Overview of Company Histories

Fanuc, founded in 1956 in Japan, specializes in automation products and robotics, rapidly becoming a global leader in CNC systems and industrial robots. ABB, established in 1988 through the merger of Sweden's ASEA and Switzerland's Brown Boveri, has a diversified portfolio including robotics, electrification, and automation technologies, emphasizing innovation in industrial automation and sustainable solutions. Both companies have profoundly influenced manufacturing automation, with Fanuc focusing on precision robotics and ABB integrating comprehensive industrial automation systems.

Core Technologies and Innovations

Fanuc leads in CNC control systems and AI-driven robotics, emphasizing precision and automation efficiency through proprietary adaptive control algorithms. ABB excels in collaborative robots (cobots) and integrated digital solutions, leveraging advanced sensor fusion and real-time data analytics to enhance industrial productivity. Your choice depends on whether you prioritize Fanuc's high-precision automation or ABB's innovative human-robot collaboration and connectivity technologies.

Product Range and Offerings

Fanuc specializes in industrial automation with a strong emphasis on CNC systems, robotics, and factory automation solutions designed for manufacturing sectors like automotive and electronics. ABB offers a broader range of products encompassing robotics, electrification, motion, and industrial automation, targeting diverse industries such as utilities, transportation, and infrastructure. Both companies provide advanced robotic arms and automation software, but Fanuc's portfolio is more focused on high-precision robotics and CNC machinery, while ABB delivers integrated solutions combining robotics with electrical and digital technologies.

Industrial Applications and Use Cases

Fanuc dominates in automotive assembly and CNC machining industries with its precise robotic arms designed for welding, painting, and material handling. ABB excels in logistics automation and food processing with flexible, scalable robot solutions tailored for palletizing, packaging, and quality inspection. Your choice between Fanuc and ABB should consider the specific industrial applications and use cases where each brand's strengths align with your production goals.

Ease of Integration and Programming

Fanuc robots offer a highly intuitive programming interface with comprehensive support for seamless integration into existing manufacturing systems, making them ideal for users seeking streamlined deployment. ABB provides advanced flexibility in programming through its RobotStudio software, enabling offline programming and simulation that optimize integration processes. Your choice depends on whether you prioritize Fanuc's user-friendly setup or ABB's robust, simulation-driven programming capabilities.

Performance and Reliability Comparison

Fanuc robots consistently deliver high precision and speed, making them ideal for demanding manufacturing environments where cycle time and accuracy are critical. ABB robots are renowned for their advanced control systems and robust design, providing reliable operation even in harsh industrial conditions. Both brands offer exceptional uptime and low maintenance requirements, but Fanuc often excels in repeatability while ABB emphasizes energy efficiency and integration flexibility.

Global Presence and Market Share

Fanuc and ABB dominate the industrial robotics market with extensive global presence and significant market shares. Fanuc holds a leading position with over 28% of the global robot market, operating manufacturing facilities and sales offices across Asia, Europe, and the Americas. ABB maintains a strong footprint in more than 100 countries, leveraging its diverse automation portfolio to capture roughly 14% of the global robotics market, ensuring your industrial automation needs are met worldwide.

Customer Support and Service Networks

Fanuc offers an extensive global customer support network with over 230 locations, providing rapid technical assistance and comprehensive training programs to ensure minimal downtime. ABB maintains a strong aftermarket service system, featuring localized service centers and certified technicians to deliver prompt maintenance and spare parts availability. Your choice between Fanuc and ABB should consider the proximity and responsiveness of their support teams to match your operational needs.

Pricing and Cost Effectiveness

Fanuc robots generally offer competitive pricing with a strong focus on reliability and extensive support, making them cost-effective for long-term industrial automation projects. ABB provides a broader range of robot models, including high-precision options, often at a premium cost but delivering advanced features that can reduce operational expenses over time. Your choice between Fanuc and ABB will depend on balancing initial investment against the specific performance and maintenance benefits required for your application.

Fanuc vs ABB Infographic

libmatt.com

libmatt.com