Pick-to-light and put-to-light are warehouse technologies designed to increase order accuracy and efficiency. While pick-to-light guides operators to accurately pick items from storage locations, put-to-light directs them to place items into correct bins, optimizing Your inventory management and fulfillment processes.

Table of Comparison

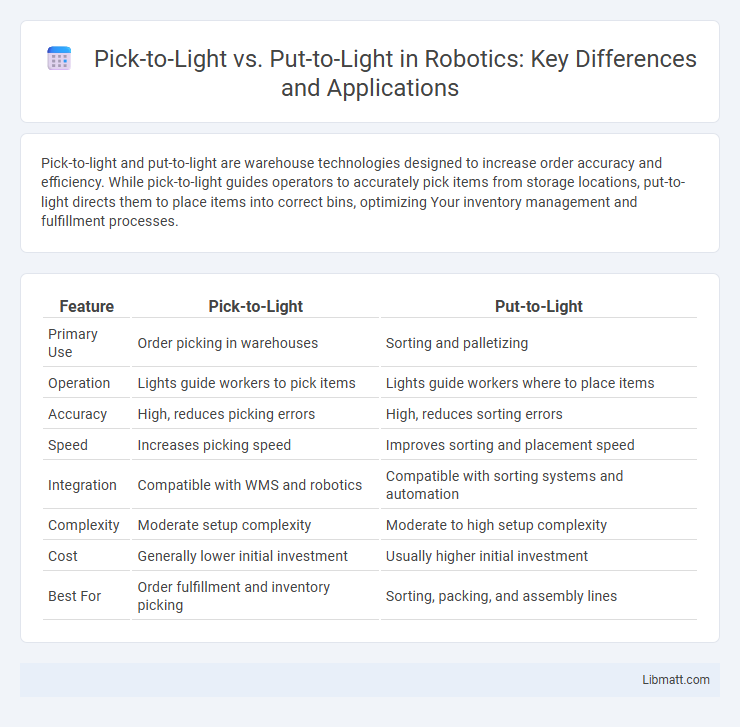

| Feature | Pick-to-Light | Put-to-Light |

|---|---|---|

| Primary Use | Order picking in warehouses | Sorting and palletizing |

| Operation | Lights guide workers to pick items | Lights guide workers where to place items |

| Accuracy | High, reduces picking errors | High, reduces sorting errors |

| Speed | Increases picking speed | Improves sorting and placement speed |

| Integration | Compatible with WMS and robotics | Compatible with sorting systems and automation |

| Complexity | Moderate setup complexity | Moderate to high setup complexity |

| Cost | Generally lower initial investment | Usually higher initial investment |

| Best For | Order fulfillment and inventory picking | Sorting, packing, and assembly lines |

Overview of Pick-to-Light and Put-to-Light Systems

Pick-to-Light systems guide warehouse operators to specific locations using illuminated displays that indicate the quantity of items to pick, streamlining order fulfillment and reducing errors. Put-to-Light systems use similar illuminated indicators to direct operators where to place incoming products during sorting or replenishment processes, enhancing accuracy and efficiency in inventory management. Both technologies improve workflow visibility, speed, and accuracy in logistics operations by leveraging visual cues for task execution.

Key Differences Between Pick-to-Light and Put-to-Light

Pick-to-light systems guide warehouse workers by illuminating specific locations to efficiently pick items for order fulfillment, enhancing picking speed and accuracy. Put-to-light technology directs operators to place items into designated locations, optimizing sorting and replenishment processes with real-time verification. The key differences lie in their application focus: pick-to-light improves order picking efficiency, while put-to-light streamlines sorting and inventory allocation.

How Pick-to-Light Technology Works

Pick-to-light technology works by guiding warehouse operators with illuminated displays mounted on storage locations, indicating the specific items and quantities to pick. When an operator picks the item, they confirm the action by pressing a button, which updates the system in real-time to ensure accurate and efficient order fulfillment. This hands-free, visual communication method streamlines your picking process by reducing errors and increasing speed.

How Put-to-Light Technology Functions

Put-to-light technology guides operators during order fulfillment by illuminating specific locations where items must be placed, ensuring accuracy and efficiency. Each bin or slot lights up with a signal prompting the operator to deposit the correct quantity, minimizing errors in sorting and packing processes. You can optimize warehouse operations by integrating put-to-light systems that streamline item distribution and improve overall workflow speed.

Core Benefits of Pick-to-Light Solutions

Pick-to-light solutions enhance warehouse efficiency by reducing picking errors through visual cues, which streamline order fulfillment processes and increase accuracy rates by up to 99%. These systems improve worker productivity by minimizing search time and enabling faster item location, leading to significant labor cost savings. Integration with warehouse management systems (WMS) allows real-time inventory updates, improving stock accuracy and reducing out-of-stock incidents.

Main Advantages of Put-to-Light Systems

Put-to-light systems significantly increase order accuracy and efficiency by guiding operators to the correct storage locations using illuminated displays, minimizing errors in sorting and packing processes. These systems reduce training time and improve productivity by providing clear visual cues, making them ideal for complex order fulfillment environments with high SKU variability. Your warehouse operations benefit from enhanced scalability and adaptability, supporting faster throughput and better inventory management compared to traditional manual methods.

Typical Applications in Warehousing and Distribution

Pick-to-light systems are commonly used in order fulfillment environments where accuracy and speed are critical, such as e-commerce warehouses and retail distribution centers. Put-to-light technology excels in sorting and shipping operations, enabling efficient allocation of products to multiple orders, especially in high-volume distribution hubs. Your choice between these systems depends on whether your primary need is precision picking or streamlined sorting processes.

Factors to Consider When Choosing a System

When choosing between pick-to-light and put-to-light systems, key factors include order volume, accuracy requirements, and warehouse layout. Pick-to-light excels in high-velocity order picking environments where speed and accuracy are critical, while put-to-light is ideal for sorting and replenishment tasks with multiple destinations. Evaluating Your operational needs, space constraints, and integration capabilities with existing warehouse management systems will guide the optimal selection for maximizing efficiency.

Cost Comparison: Pick-to-Light vs Put-to-Light

Pick-to-light systems generally incur higher initial costs due to more complex hardware required for accurate item picking, whereas put-to-light solutions often have lower upfront expenses focused on efficient item sorting and placement. Operational costs for pick-to-light can be reduced through increased picking speed and accuracy, leading to faster order fulfillment compared to put-to-light, which optimizes sorting but may require more manual handling. Long-term cost efficiency depends on warehouse workflows, with pick-to-light favored in high-volume picking environments and put-to-light preferred for order consolidation and sorting tasks.

Future Trends in Light-Directed Order Fulfillment

Pick-to-light and put-to-light systems are evolving rapidly with the integration of advanced AI and IoT technologies, enhancing accuracy and efficiency in light-directed order fulfillment. Future trends emphasize real-time data analytics, adaptive light displays, and voice-assisted commands to streamline warehouse operations and reduce picking errors. The rise of autonomous mobile robots combined with light-directed technology is set to revolutionize dynamic storage and order processing workflows.

Pick-to-light vs Put-to-light Infographic

libmatt.com

libmatt.com