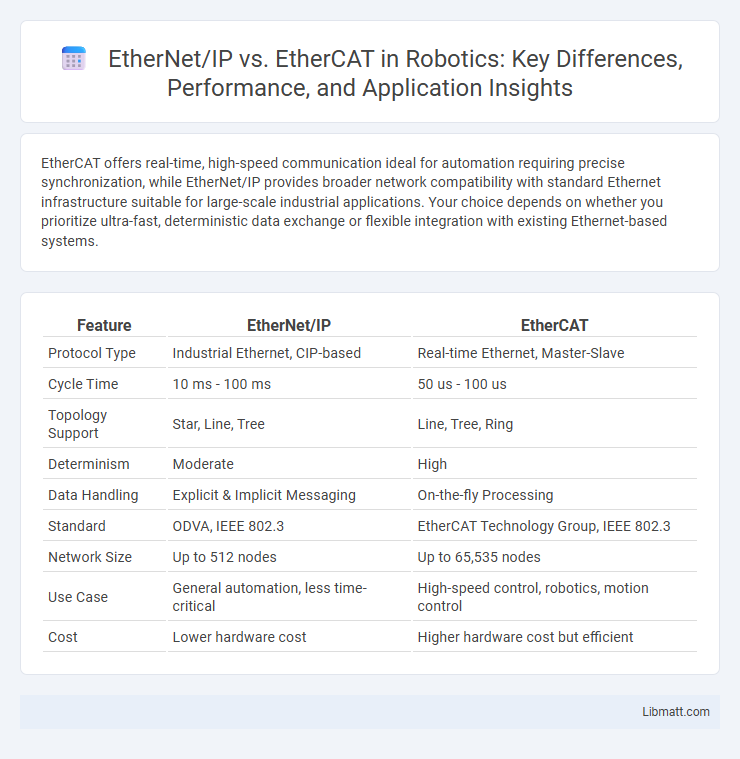

EtherCAT offers real-time, high-speed communication ideal for automation requiring precise synchronization, while EtherNet/IP provides broader network compatibility with standard Ethernet infrastructure suitable for large-scale industrial applications. Your choice depends on whether you prioritize ultra-fast, deterministic data exchange or flexible integration with existing Ethernet-based systems.

Table of Comparison

| Feature | EtherNet/IP | EtherCAT |

|---|---|---|

| Protocol Type | Industrial Ethernet, CIP-based | Real-time Ethernet, Master-Slave |

| Cycle Time | 10 ms - 100 ms | 50 us - 100 us |

| Topology Support | Star, Line, Tree | Line, Tree, Ring |

| Determinism | Moderate | High |

| Data Handling | Explicit & Implicit Messaging | On-the-fly Processing |

| Standard | ODVA, IEEE 802.3 | EtherCAT Technology Group, IEEE 802.3 |

| Network Size | Up to 512 nodes | Up to 65,535 nodes |

| Use Case | General automation, less time-critical | High-speed control, robotics, motion control |

| Cost | Lower hardware cost | Higher hardware cost but efficient |

Introduction to Industrial Ethernet Protocols

EtherNet/IP and EtherCAT are prominent Industrial Ethernet protocols designed to facilitate real-time communication in automation systems. EtherNet/IP operates on standard Ethernet infrastructure using CIP (Common Industrial Protocol), enabling seamless device interoperability and network scalability. EtherCAT utilizes a unique on-the-fly processing mechanism, delivering high-speed, deterministic data exchange ideal for time-critical applications and precise motion control.

What is EtherNet/IP?

EtherNet/IP is an industrial networking protocol that uses standard Ethernet and TCP/IP technologies to enable real-time communication and control in automation systems. It supports a variety of devices and applications by leveraging the Common Industrial Protocol (CIP), ensuring interoperability across different manufacturers. Your industrial network benefits from EtherNet/IP's scalability, flexibility, and wide industry adoption, making it ideal for complex automation tasks.

What is EtherCAT?

EtherCAT (Ethernet for Control Automation Technology) is a high-performance, real-time industrial Ethernet protocol designed for automation applications requiring fast and precise communication. It operates by processing Ethernet frames on the fly, allowing minimal delay and synchronization between devices, which makes it ideal for motion control and complex machine automation. You benefit from EtherCAT's deterministic timing and scalability, crucial for optimizing real-time control networks compared to traditional EtherNet/IP systems.

Key Differences Between EtherNet/IP and EtherCAT

EtherNet/IP utilizes standard Ethernet infrastructure and the Common Industrial Protocol (CIP) for versatile industrial automation with flexible network topologies. EtherCAT operates with a unique on-the-fly processing mechanism, delivering ultra-fast communication and deterministic real-time performance by processing data as it passes through each node. Key differences include EtherNet/IP's compatibility with conventional IT networks and ease of integration versus EtherCAT's superiority in high-speed, low-latency control applications requiring precise synchronization.

Performance and Speed Comparison

EtherCAT offers superior real-time performance with cycle times as low as 100 microseconds, making it ideal for high-speed automation applications, whereas EtherNet/IP typically provides cycle times around 1-10 milliseconds. EtherCAT's on-the-fly processing architecture minimizes communication delays by processing data as it passes through each node, contrasting with EtherNet/IP's standard Ethernet communication which introduces higher latency due to scanning and protocol overhead. The deterministic nature of EtherCAT ensures consistent, low-jitter data exchange, outperforming EtherNet/IP in scenarios requiring precise synchronization and rapid data updates.

Network Topology and Scalability

EtherNet/IP supports star, linear, and tree topologies, making it flexible for various industrial networks, and its scalability is suitable for large systems with hundreds of nodes. EtherCAT uses a ring or line topology optimized for real-time communication, allowing high-speed data exchange with minimal latency, ideal for applications requiring precise synchronization. Your choice depends on whether you prioritize broad network adaptability and scalability (EtherNet/IP) or ultra-fast, deterministic communication in scalable but more structured topologies (EtherCAT).

Real-Time Communication Capabilities

EtherNet/IP and EtherCAT both offer robust real-time communication capabilities but differ significantly in latency and determinism. EtherCAT utilizes a master-slave protocol with on-the-fly processing, achieving cycle times as low as a few microseconds, making it ideal for high-precision automation tasks. Your choice depends on the need for ultra-low latency and synchronized data exchange, where EtherCAT excels, versus broader compatibility and integration flexibility offered by EtherNet/IP.

Compatibility and Device Support

EtherNet/IP offers extensive device compatibility through its widespread adoption in industrial automation, supporting a broad range of standard Ethernet devices and leveraging the Common Industrial Protocol (CIP) for seamless integration. EtherCAT excels in real-time performance and deterministic communication with specialized device profiles, but its device support is more niche, typically limited to compatible EtherCAT controllers and peripherals. Industrial networks requiring standardized Ethernet connectivity benefit from EtherNet/IP's broad compatibility, while applications demanding high-speed, synchronized control favor EtherCAT's optimized device ecosystem.

Application Areas and Industry Usage

EtherNet/IP is widely adopted in process automation, manufacturing, and industrial control due to its compatibility with standard Ethernet and CIP (Common Industrial Protocol), making it suitable for large-scale, complex networks. EtherCAT excels in high-performance motion control and robotics applications, offering precise synchronization and low latency, preferred in automotive assembly lines and semiconductor manufacturing. Both protocols support real-time communication but serve distinct industry needs based on application complexity and performance requirements.

Choosing the Right Protocol for Your Automation Needs

EtherNet/IP offers extensive device interoperability and is widely supported for large-scale industrial automation with standard Ethernet infrastructure, making it ideal for complex networks requiring robust data handling. EtherCAT excels in real-time performance and low latency, providing precise synchronization for high-speed control applications such as robotics and motion control. Selecting the right protocol depends on factors like network complexity, required communication speed, scalability, and compatibility with existing equipment.

EtherNet/IP vs EtherCAT Infographic

libmatt.com

libmatt.com