Laser triangulation offers high precision by measuring the time or angle of reflected laser light to create accurate 3D models, making it ideal for detailed inspection tasks. Structured light projects a pattern onto the surface and analyzes the deformation to capture complex shapes quickly, providing faster scanning of larger areas without sacrificing your measurement accuracy.

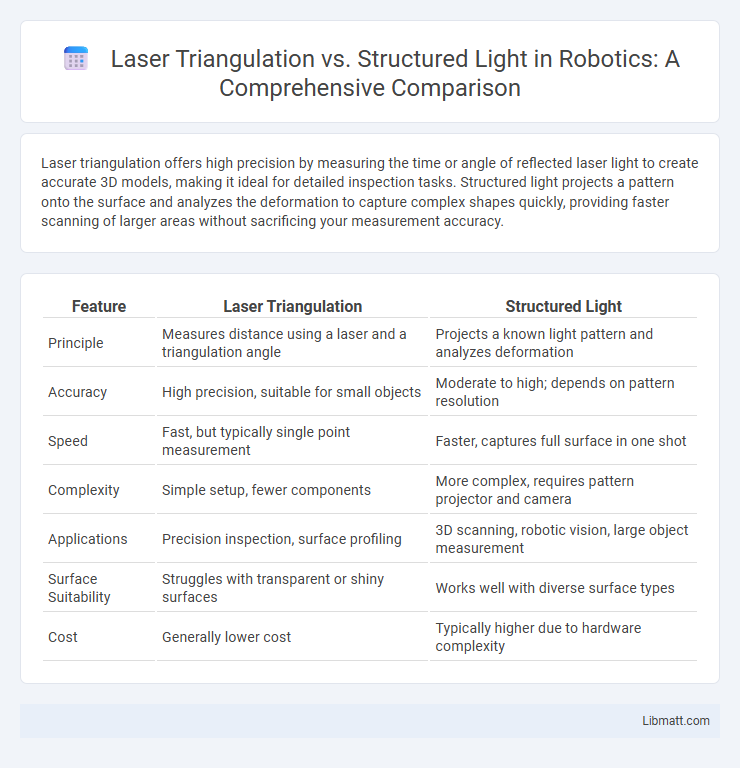

Table of Comparison

| Feature | Laser Triangulation | Structured Light |

|---|---|---|

| Principle | Measures distance using a laser and a triangulation angle | Projects a known light pattern and analyzes deformation |

| Accuracy | High precision, suitable for small objects | Moderate to high; depends on pattern resolution |

| Speed | Fast, but typically single point measurement | Faster, captures full surface in one shot |

| Complexity | Simple setup, fewer components | More complex, requires pattern projector and camera |

| Applications | Precision inspection, surface profiling | 3D scanning, robotic vision, large object measurement |

| Surface Suitability | Struggles with transparent or shiny surfaces | Works well with diverse surface types |

| Cost | Generally lower cost | Typically higher due to hardware complexity |

Introduction to 3D Scanning Technologies

Laser triangulation uses a laser beam projected onto an object, capturing the reflected light with a sensor to calculate precise distance and surface geometry, making it ideal for high-accuracy 3D scanning in manufacturing and quality control. Structured light projects a known pattern onto an object's surface, and a camera captures the deformation of this pattern to generate detailed 3D models, commonly applied in facial recognition and complex surface mapping. Both technologies offer non-contact measurement solutions, but laser triangulation excels in precision over small areas while structured light covers larger surfaces quicker.

What Is Laser Triangulation?

Laser triangulation is a precise 3D scanning method that uses a laser beam projected onto a surface and a sensor positioned at a fixed angle to measure the reflected light, calculating distance and surface geometry. This technique excels in capturing detailed profiles for quality control, reverse engineering, and industrial automation. Your choice between laser triangulation and structured light depends on factors like scanning speed, surface texture, and measurement accuracy required.

How Structured Light Scanning Works

Structured light scanning projects a known pattern, such as grids or stripes, onto an object's surface and captures the deformation of this pattern with cameras to calculate depth information. By analyzing the distortion of the projected light, the system reconstructs a detailed 3D model with high accuracy and rapid acquisition speed. Unlike laser triangulation, which uses a single laser point or line, structured light can cover larger areas simultaneously, enhancing measurement efficiency for complex geometries.

Accuracy Comparison: Laser Triangulation vs Structured Light

Laser triangulation typically offers higher accuracy in measuring small, precise details due to its focused laser point and precise angle calculations. Structured light systems provide a broader area of measurement but may have lower accuracy in capturing fine surface details due to the reliance on pattern projection and camera resolution. Accuracy in laser triangulation can reach micrometer levels, whereas structured light accuracy often ranges from sub-millimeter to millimeter precision depending on the system configuration.

Speed and Efficiency Differences

Laser triangulation offers faster data acquisition speeds suitable for applications requiring rapid, point-by-point measurements, making it highly efficient for inspecting small objects or intricate details. Structured light captures entire surface geometries simultaneously, providing greater throughput for scanning larger areas but may require more processing time, impacting overall speed. Your choice between the two depends on whether prioritizing point accuracy with quick reads or capturing comprehensive 3D shapes efficiently is more critical.

Material and Surface Compatibility

Laser triangulation is highly effective on opaque and diffusely reflective materials, offering precise measurements on surfaces with varying textures and colors. Structured light excels in capturing detailed 3D data from complex surfaces, including semi-transparent and glossy materials, by projecting a pattern and analyzing distortions. Your choice depends on the specific material properties and surface reflectivity to achieve optimal accuracy and data quality.

Resolution and Detail Capture

Laser triangulation offers high resolution and precise detail capture by measuring the exact point where a laser beam intersects an object's surface, making it ideal for capturing fine textures and small features. Structured light scanners project a pattern onto the subject, capturing surface details by analyzing distortion, which can achieve excellent resolution over larger areas but may struggle with very fine detail compared to laser triangulation. Your choice depends on whether you prioritize pinpoint accuracy with intricate details or broader coverage with good overall resolution.

Cost Implications and ROI

Laser triangulation systems typically involve higher initial costs due to precise laser components and calibration requirements, but they offer excellent accuracy and long-term reliability, which can enhance Your return on investment in high-precision applications. Structured light scanners usually have lower upfront costs and faster scanning speeds, making them cost-effective for volume inspection and 3D modeling projects with moderate precision needs. Evaluating application-specific requirements is crucial to balance cost implications and maximize ROI between these two optical measurement technologies.

Typical Applications and Industry Use Cases

Laser triangulation excels in precise distance measurement and surface profiling, making it ideal for quality control in automotive and electronics manufacturing. Structured light technology is widely used for 3D scanning, object recognition, and inspection in industries such as robotics, medical imaging, and consumer electronics. Your choice depends on whether the application requires high-accuracy point measurements (laser triangulation) or full-field 3D shape capture (structured light).

Choosing the Right Technology for Your Needs

Laser triangulation offers high precision and fast measurement speeds, making it ideal for applications requiring detailed surface profiling and real-time analysis. Structured light excels in capturing complex shapes and larger areas with excellent accuracy, suitable for quality inspection and 3D scanning in various industries. Assess your specific measurement accuracy requirements, object size, and environmental conditions to choose the technology that best fits your needs.

Laser triangulation vs Structured light Infographic

libmatt.com

libmatt.com