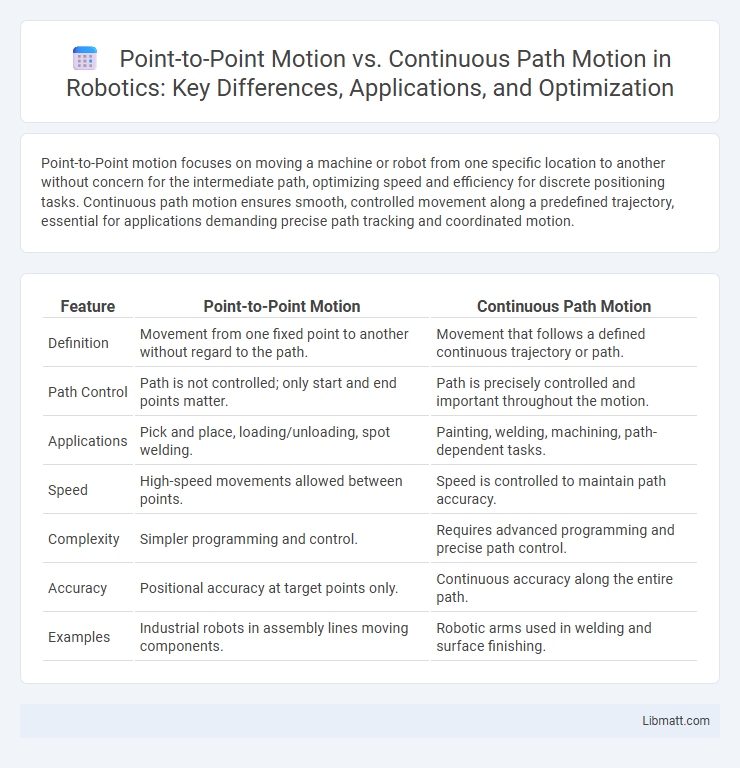

Point-to-Point motion focuses on moving a machine or robot from one specific location to another without concern for the intermediate path, optimizing speed and efficiency for discrete positioning tasks. Continuous path motion ensures smooth, controlled movement along a predefined trajectory, essential for applications demanding precise path tracking and coordinated motion.

Table of Comparison

| Feature | Point-to-Point Motion | Continuous Path Motion |

|---|---|---|

| Definition | Movement from one fixed point to another without regard to the path. | Movement that follows a defined continuous trajectory or path. |

| Path Control | Path is not controlled; only start and end points matter. | Path is precisely controlled and important throughout the motion. |

| Applications | Pick and place, loading/unloading, spot welding. | Painting, welding, machining, path-dependent tasks. |

| Speed | High-speed movements allowed between points. | Speed is controlled to maintain path accuracy. |

| Complexity | Simpler programming and control. | Requires advanced programming and precise path control. |

| Accuracy | Positional accuracy at target points only. | Continuous accuracy along the entire path. |

| Examples | Industrial robots in assembly lines moving components. | Robotic arms used in welding and surface finishing. |

Introduction to Industrial Robotic Motion

Industrial robotic motion is classified into Point-to-Point (PTP) and Continuous Path (CP) motion, each serving distinct automation needs. Point-to-Point motion moves the robot between discrete positions without controlling the path between points, ideal for tasks like pick-and-place or assembly. Continuous Path motion ensures the robot follows a precise trajectory, critical for welding, painting, or milling applications where path accuracy affects quality.

Defining Point-to-Point (PTP) Motion

Point-to-Point (PTP) Motion involves moving a tool or robotic arm directly from one specific coordinate to another without regard for the path taken between points. The primary focus in PTP motion is on reaching the precise start and end positions efficiently, making it ideal for tasks like pick-and-place operations or spot welding. This type of motion optimizes speed and accuracy for discrete movements rather than smooth, continuous trajectories.

Explaining Continuous Path (CP) Motion

Continuous Path (CP) Motion entails the controlled movement of a machine tool or robotic arm along a predefined, uninterrupted trajectory, allowing precise shaping and contouring of complex surfaces. Unlike Point-to-Point (PTP) motion, CP motion ensures smooth transitions between intermediate positions, maintaining consistent velocity and acceleration profiles essential for applications such as milling, welding, and robotic painting. This type of motion control relies heavily on advanced interpolation algorithms to execute complex paths with high accuracy and surface finish quality.

Key Differences Between PTP and CP Motion

Point-to-Point (PTP) motion moves a robotic arm from one specified position to another without controlling the path taken, focusing on endpoint accuracy and speed. Continuous Path (CP) motion, by contrast, ensures the robotic arm follows a precise trajectory, crucial for tasks requiring smooth, coordinated movements such as welding or painting. Your choice depends on the task requirements: PTP is optimal for discrete positioning, while CP excels in applications demanding exact path control.

Applications of Point-to-Point Motion

Point-to-Point Motion is widely used in industrial robotics for tasks requiring precise movement between specific locations, such as pick-and-place operations, assembly, and machine loading. Your automation system benefits from this approach by optimizing cycle times and reducing errors in repetitive motions. Its application in CNC machines and robotic arms ensures efficient handling of discrete task points without concern for path trajectory.

Applications of Continuous Path Motion

Continuous path motion is essential in applications such as welding, painting, and milling where precise, smooth toolpaths are required to maintain consistent contact and quality. CNC machines rely on continuous path motion to generate complex curves and contours in automotive and aerospace manufacturing. Your production process benefits from enhanced accuracy and surface finish when using continuous path motion for intricate, non-linear trajectories.

Advantages and Limitations of PTP Motion

Point-to-point (PTP) motion offers precise control by moving a device directly from one specified location to another without concern for the trajectory, making it ideal for applications like pick-and-place tasks where speed and accuracy are paramount. Its advantages include simplified programming, faster cycle times due to optimized travel paths, and reduced computational demands compared to continuous path motion. However, PTP motion's limitation lies in the lack of control over the intermediate path, which can lead to less smooth movements and potential issues in tasks requiring accurate path tracking, such as welding or painting.

Advantages and Limitations of CP Motion

Continuous Path (CP) motion offers precise control over the tool's trajectory, enabling smooth and complex movements essential for applications like contouring and multi-axis machining. Advantages include enhanced surface finish quality and reduced cycle times due to constant path tracking, while limitations involve higher computational requirements and increased system complexity. CP motion is less suited for simple operations where exact path control is unnecessary, potentially leading to inefficient use of resources.

Choosing the Right Motion Type for Industrial Tasks

Selecting between point-to-point motion and continuous path motion depends on the specific industrial task requirements. Point-to-point motion is ideal for applications needing precise positioning, such as assembly or pick-and-place operations, where accuracy at discrete points matters most. Continuous path motion suits tasks like welding or painting, demanding smooth, uninterrupted tool movement to ensure consistent quality throughout the process.

Future Trends in Robotic Motion Control

Future trends in robotic motion control emphasize enhanced precision and adaptability in both Point-to-Point Motion and Continuous Path Motion through advanced AI algorithms and machine learning integration. Innovations in sensor technology and real-time data processing enable robots to optimize path planning dynamically, improving efficiency for complex industrial and service applications. Your systems will benefit from these developments by achieving greater accuracy, faster response times, and seamless adaptation to changing operational environments.

Point-to-Point Motion vs Continuous Path Motion Infographic

libmatt.com

libmatt.com