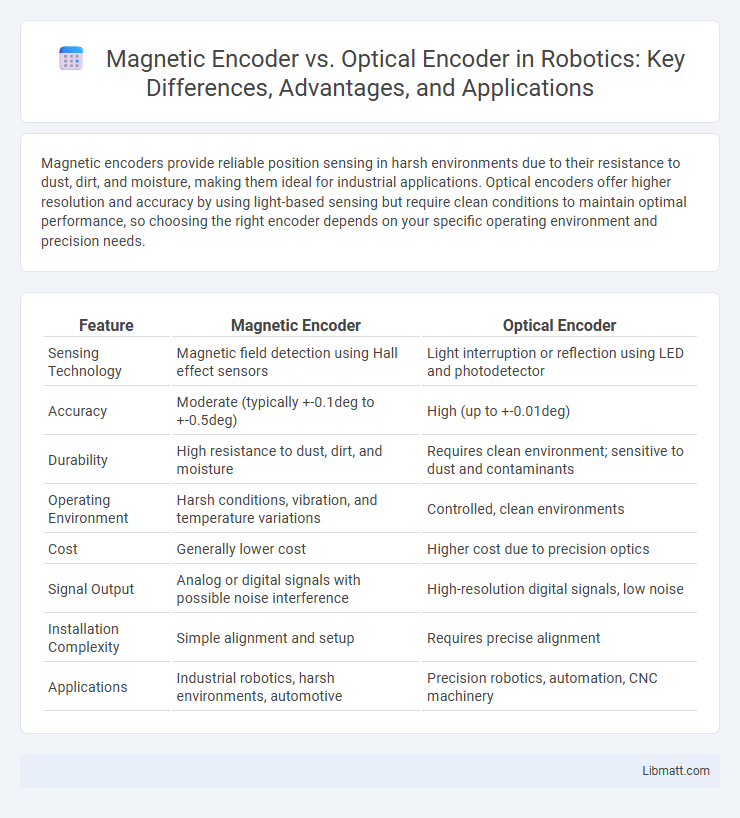

Magnetic encoders provide reliable position sensing in harsh environments due to their resistance to dust, dirt, and moisture, making them ideal for industrial applications. Optical encoders offer higher resolution and accuracy by using light-based sensing but require clean conditions to maintain optimal performance, so choosing the right encoder depends on your specific operating environment and precision needs.

Table of Comparison

| Feature | Magnetic Encoder | Optical Encoder |

|---|---|---|

| Sensing Technology | Magnetic field detection using Hall effect sensors | Light interruption or reflection using LED and photodetector |

| Accuracy | Moderate (typically +-0.1deg to +-0.5deg) | High (up to +-0.01deg) |

| Durability | High resistance to dust, dirt, and moisture | Requires clean environment; sensitive to dust and contaminants |

| Operating Environment | Harsh conditions, vibration, and temperature variations | Controlled, clean environments |

| Cost | Generally lower cost | Higher cost due to precision optics |

| Signal Output | Analog or digital signals with possible noise interference | High-resolution digital signals, low noise |

| Installation Complexity | Simple alignment and setup | Requires precise alignment |

| Applications | Industrial robotics, harsh environments, automotive | Precision robotics, automation, CNC machinery |

Introduction to Magnetic and Optical Encoders

Magnetic encoders utilize magnetic fields and sensors like Hall effect devices to detect position or motion, offering robustness in harsh environments with dust, oil, or moisture. Optical encoders employ light sources and photodetectors to read coded patterns on disks, providing high resolution and precision ideal for clean and controlled settings. Your choice depends on application requirements such as environmental conditions and accuracy needs.

How Magnetic Encoders Work

Magnetic encoders function by detecting changes in a magnetic field generated by a rotating magnet attached to a shaft, utilizing Hall effect sensors or magnetoresistive sensors to convert these variations into digital signals. These signals provide precise information about position, speed, or direction, making magnetic encoders highly resistant to dust, dirt, and moisture compared to optical encoders. Your choice of a magnetic encoder ensures reliable performance in harsh environments while maintaining accurate motion control.

How Optical Encoders Work

Optical encoders operate by projecting a light source, often an LED, through a precision-coded disc with transparent and opaque segments, which modulates the light intensity received by photodetector sensors. The interruption pattern of the light beam generates electrical signals that correspond to precise positional information, enabling accurate measurement of rotational or linear movement. This method offers high resolution and immunity to magnetic interference, making optical encoders ideal for applications demanding precise feedback in robotics, CNC machinery, and industrial automation.

Key Differences Between Magnetic and Optical Encoders

Magnetic encoders utilize magnetic fields to detect position changes, offering robust performance in harsh environments with dust, dirt, and moisture, while optical encoders rely on light patterns and sensors, providing higher resolution and precision under clean conditions. Magnetic encoders typically feature longer lifespans due to less susceptibility to contamination and mechanical wear, whereas optical encoders excel in applications demanding fine positional accuracy and fast response times. Your choice between magnetic and optical encoders depends on the required environment tolerance, precision level, and operational durability.

Accuracy and Resolution Comparison

Magnetic encoders typically offer moderate accuracy ranging from +-0.1deg to +-0.5deg, while optical encoders provide higher precision with accuracy often within +-0.01deg to +-0.05deg. Resolution for optical encoders can reach up to several thousand pulses per revolution (PPR), surpassing magnetic encoders which commonly deliver lower resolution around a few hundred PPR. The inherent design of optical encoders, using light and photodetectors, enables finer signal differentiation compared to magnetic encoders that rely on magnetic field variations, influencing both accuracy and resolution performance.

Environmental Suitability: Durability and Reliability

Magnetic encoders excel in harsh environments due to their resistance to dust, dirt, moisture, and vibrations, ensuring consistent durability and reliable performance in industrial settings. Optical encoders, while offering high precision, are more sensitive to contaminants and require clean conditions to maintain accuracy and longevity. Your choice should consider the operational environment, prioritizing magnetic encoders for rugged, dirt-prone applications and optical encoders for cleaner, controlled settings.

Cost Analysis: Magnetic vs Optical Encoders

Magnetic encoders generally offer a more cost-effective solution compared to optical encoders due to their simpler design and lower manufacturing expenses. Optical encoders require precise optical components and clean operating environments, which increase their initial cost and maintenance budget. Your choice between magnetic and optical encoders should consider long-term costs, including installation and upkeep, alongside upfront investment.

Application Areas and Use Cases

Magnetic encoders excel in harsh environments like automotive, industrial machinery, and robotics due to their durability against dust, dirt, and moisture, making them ideal for applications requiring reliable position sensing in challenging conditions. Optical encoders are favored in high-precision fields such as CNC machines, semiconductor manufacturing, and medical devices, where accurate and high-resolution feedback is critical for precise motion control. Both encoder types serve crucial roles in automation, but magnetic encoders prioritize robustness, while optical encoders emphasize measurement accuracy and fine resolution.

Installation and Maintenance Considerations

Magnetic encoders offer simpler installation due to their non-contact design and greater tolerance to misalignment, reducing the need for precise shaft alignment compared to optical encoders. Optical encoders require clean environments and regular maintenance to prevent dirt and dust from affecting sensor accuracy, whereas magnetic encoders perform reliably in harsher conditions with minimal upkeep. Your choice hinges on the balance between ease of installation and maintenance demands, with magnetic encoders providing a more robust and low-maintenance solution.

Choosing the Right Encoder for Your Needs

Magnetic encoders offer robust performance in harsh environments due to their resistance to dust, dirt, and moisture, making them ideal for industrial applications requiring durability. Optical encoders provide higher resolution and precision, suitable for tasks demanding exact position feedback, such as robotics and CNC machinery. Selecting the right encoder depends on balancing environmental conditions, required accuracy, and budget constraints to ensure optimal system performance.

Magnetic Encoder vs Optical Encoder Infographic

libmatt.com

libmatt.com