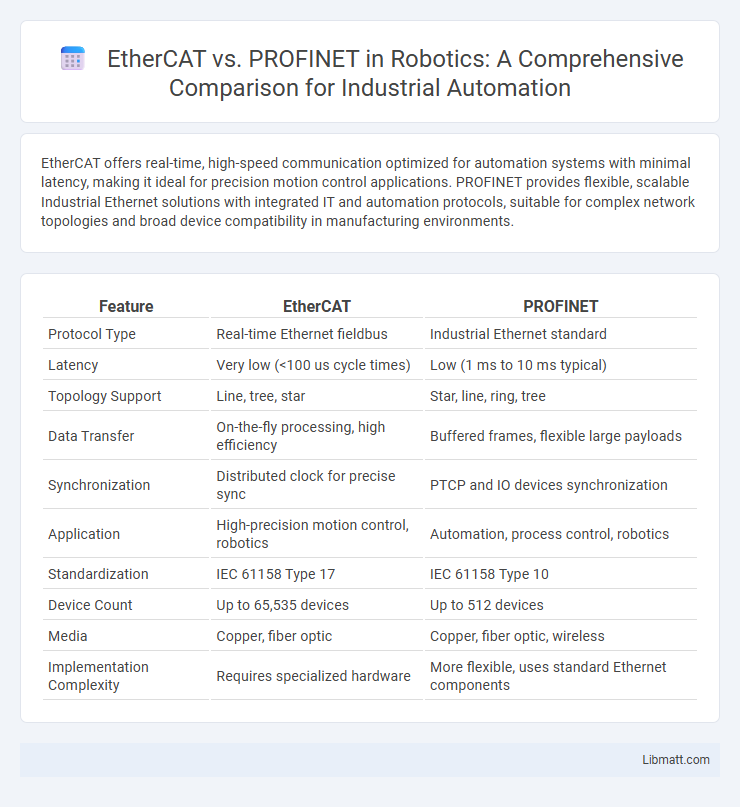

EtherCAT offers real-time, high-speed communication optimized for automation systems with minimal latency, making it ideal for precision motion control applications. PROFINET provides flexible, scalable Industrial Ethernet solutions with integrated IT and automation protocols, suitable for complex network topologies and broad device compatibility in manufacturing environments.

Table of Comparison

| Feature | EtherCAT | PROFINET |

|---|---|---|

| Protocol Type | Real-time Ethernet fieldbus | Industrial Ethernet standard |

| Latency | Very low (<100 us cycle times) | Low (1 ms to 10 ms typical) |

| Topology Support | Line, tree, star | Star, line, ring, tree |

| Data Transfer | On-the-fly processing, high efficiency | Buffered frames, flexible large payloads |

| Synchronization | Distributed clock for precise sync | PTCP and IO devices synchronization |

| Application | High-precision motion control, robotics | Automation, process control, robotics |

| Standardization | IEC 61158 Type 17 | IEC 61158 Type 10 |

| Device Count | Up to 65,535 devices | Up to 512 devices |

| Media | Copper, fiber optic | Copper, fiber optic, wireless |

| Implementation Complexity | Requires specialized hardware | More flexible, uses standard Ethernet components |

Introduction to EtherCAT and PROFINET

EtherCAT (Ethernet for Control Automation Technology) is a high-performance, real-time Ethernet protocol designed for fast and efficient communication in industrial automation systems. PROFINET (Process Field Network) is an industrial Ethernet standard developed for flexible and scalable automation, supporting real-time data exchange and integration with various field devices. Both protocols facilitate reliable machine-to-machine communication but differ in architecture and real-time capabilities tailored to specific automation needs.

Key Features Comparison

EtherCAT offers high-speed communication with cycle times as low as 100 microseconds, ideal for real-time control in demanding automation environments, while PROFINET excels in flexible topology and broad device interoperability supporting both real-time and non-real-time data exchange. EtherCAT's distributed clock technology ensures precise synchronization across devices, whereas PROFINET leverages Industrial Ethernet standards for seamless integration with existing IT infrastructure. Your choice between EtherCAT and PROFINET should consider the required communication speed, network complexity, and compatibility with existing industrial equipment.

Network Architecture Differences

EtherCAT employs a master-slave network architecture featuring a ring or line topology that ensures deterministic data transmission with minimal latency through on-the-fly processing. PROFINET utilizes a star or line topology based on Ethernet switches, supporting both centralized and distributed control with priority-based traffic management. Your choice between EtherCAT's real-time, low-jitter communication and PROFINET's flexible, scalable architecture depends on specific industrial automation network requirements.

Performance and Speed Analysis

EtherCAT delivers ultra-low latency and high-speed communication with cycle times often below 100 microseconds, making it ideal for real-time industrial automation requiring precise synchronization. PROFINET offers flexible performance modes, with Real-Time (RT) cycles around 1-10 milliseconds and Isochronous Real-Time (IRT) enabling deterministic speeds for motion control, although generally slower than EtherCAT. EtherCAT's on-the-fly processing reduces delays by processing frames as they pass through nodes, resulting in superior performance for applications demanding stringent timing and rapid response.

Scalability and Flexibility

EtherCAT offers exceptional scalability with its ability to efficiently handle both small and large networks through high-speed, low-latency communication and flexible topology options like line, tree, and star configurations. PROFINET provides significant flexibility by supporting various implementation levels, from simple device communication to complex automation cells, and it integrates seamlessly with existing Ethernet infrastructure, enabling easy expansion and diverse application use cases. Both protocols excel in scalability and flexibility, but EtherCAT's optimized processing for distributed clocks and real-time data makes it particularly suitable for high-performance industrial automation systems requiring precise synchronization.

Real-Time Communication Capabilities

EtherCAT delivers ultra-fast real-time communication with cycle times as low as 100 microseconds, utilizing a unique on-the-fly processing mechanism that minimizes latency. PROFINET offers flexible real-time performance modes, including RT for typical automation tasks and IRT (Isochronous Real-Time) for high-precision applications with cycle times down to 31.25 microseconds. EtherCAT's deterministic data handling excels in synchronized motion control, while PROFINET's integration with standard Ethernet infrastructure supports both real-time and non-real-time traffic efficiently.

Compatibility and Integration

EtherCAT offers seamless integration with existing Ethernet infrastructure, ensuring high compatibility with standard network devices and simplifying implementation in diverse industrial environments. PROFINET provides robust compatibility with a wide range of automation equipment, enabling smooth integration into Siemens-based and other industrial control systems. Your choice between EtherCAT and PROFINET should consider the specific device ecosystem and system requirements for optimal network performance and interoperability.

Security Considerations

EtherCAT employs a distributed clock mechanism that minimizes packet latency but lacks built-in encryption, making it vulnerable to unauthorized access in unsecured networks. PROFINET integrates advanced security features such as ISO/IEC 27001 compliance, TLS encryption, and network segmentation to safeguard against cyber threats and data manipulation. While EtherCAT relies on external security measures like VPNs and firewalls, PROFINET's native security protocols provide enhanced protection for industrial automation environments.

Application Areas and Use Cases

EtherCAT excels in high-speed applications requiring precise synchronization, such as robotics, CNC machines, and automotive manufacturing, where real-time performance and low latency are critical. PROFINET is widely used in factory automation, process control, and large-scale industrial networks, supporting seamless integration with PLCs and field devices in complex production environments. Your choice depends on whether ultra-fast data exchange or comprehensive network management and scalability are priorities in your industrial setup.

Choosing the Right Protocol

Choosing the right industrial Ethernet protocol depends on the specific application requirements such as real-time performance, network topology, and device compatibility. EtherCAT offers ultra-fast, deterministic communication ideal for high-precision automation tasks, while PROFINET provides greater flexibility with standardized Ethernet technology and extensive support for complex network configurations. Evaluating factors like cycle time, scalability, and integration with existing systems is essential for selecting the most efficient and reliable protocol for your automation needs.

EtherCAT vs PROFINET Infographic

libmatt.com

libmatt.com