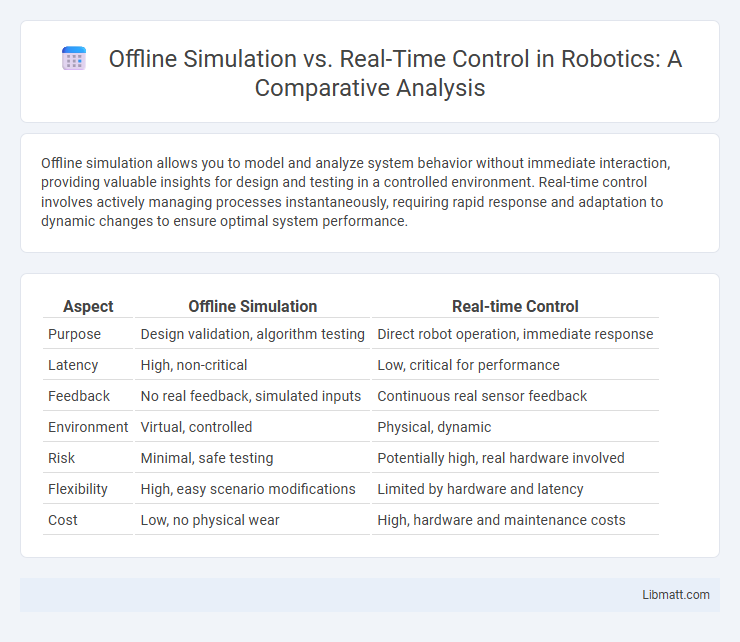

Offline simulation allows you to model and analyze system behavior without immediate interaction, providing valuable insights for design and testing in a controlled environment. Real-time control involves actively managing processes instantaneously, requiring rapid response and adaptation to dynamic changes to ensure optimal system performance.

Table of Comparison

| Aspect | Offline Simulation | Real-time Control |

|---|---|---|

| Purpose | Design validation, algorithm testing | Direct robot operation, immediate response |

| Latency | High, non-critical | Low, critical for performance |

| Feedback | No real feedback, simulated inputs | Continuous real sensor feedback |

| Environment | Virtual, controlled | Physical, dynamic |

| Risk | Minimal, safe testing | Potentially high, real hardware involved |

| Flexibility | High, easy scenario modifications | Limited by hardware and latency |

| Cost | Low, no physical wear | High, hardware and maintenance costs |

Introduction to Offline Simulation and Real-time Control

Offline simulation uses computational models to predict system behavior under various scenarios without interacting with the physical device, enabling thorough analysis and optimization before deployment. Real-time control processes data instantaneously to manage system operations actively, ensuring immediate response to dynamic environmental changes and maintaining system stability. Your choice between offline simulation and real-time control depends on the need for preliminary testing accuracy versus the requirement for live system adaptation.

Key Definitions and Concepts

Offline simulation involves modeling and analyzing system behavior in a controlled virtual environment without real-time constraints, allowing extensive testing and optimization before deployment. Real-time control refers to the direct manipulation of system parameters and processes with immediate feedback and minimal latency to maintain desired performance levels. Understanding the difference between predictive accuracy in offline simulation and the responsiveness required in real-time control is essential for effective system design and operation.

Core Differences Between Offline Simulation and Real-time Control

Offline simulation involves running models or algorithms in a controlled environment without direct interaction with physical systems, allowing extensive testing and validation of scenarios without time constraints. Real-time control requires immediate processing and response to live data inputs to manage systems or processes dynamically, ensuring timely and accurate adjustments. Your choice between the two impacts system design complexity, with offline simulation favoring analysis and optimization and real-time control prioritizing responsiveness and stability.

Advantages of Offline Simulation

Offline simulation offers significant advantages by allowing you to model and test complex systems without interrupting real-time operations, reducing risk and cost. It enables detailed analysis and optimization through extensive what-if scenarios, improving overall system reliability and performance before implementation. This approach also facilitates thorough training and troubleshooting, enhancing your ability to anticipate and address potential issues proactively.

Benefits of Real-time Control Systems

Real-time control systems enable immediate processing and response to dynamic inputs, ensuring higher accuracy and stability in critical applications such as robotics, aerospace, and manufacturing. These systems improve operational efficiency by continuously monitoring and adjusting processes, reducing downtime and the risk of errors compared to offline simulation. Your ability to implement precise adjustments in real-time enhances overall system performance and safety.

Common Applications in Industry

Offline simulation is extensively used in industries such as automotive and aerospace for designing and testing systems without interrupting production, enabling optimization of complex processes. Real-time control is critical in manufacturing automation, robotics, and energy management, where immediate feedback and adjustments maintain system stability and efficiency. Both approaches complement each other by allowing thorough system analysis and responsive operational control.

Challenges and Limitations

Offline simulation faces challenges such as limited accuracy in predicting real-time system behaviors due to model simplifications and assumptions. Real-time control struggles with latency issues and computational constraints that hinder immediate response and adaptation. Both approaches encounter limitations in handling dynamic environmental changes and unmodeled disturbances, impacting reliability and performance.

Integration Strategies for Hybrid Approaches

Hybrid approaches combine offline simulation and real-time control through seamless integration strategies such as co-simulation frameworks and hardware-in-the-loop (HIL) testing. These methods enable dynamic data exchange between pre-validated models and live control systems, enhancing system accuracy and responsiveness. By leveraging synchronized time management and model abstraction techniques, hybrid integration supports robust decision-making in complex cyber-physical environments.

Future Trends and Innovations

Future trends in offline simulation focus on integrating artificial intelligence and machine learning to enhance predictive accuracy and reduce computational time, enabling more complex system modeling. Real-time control innovations emphasize edge computing and the Internet of Things (IoT) for faster data processing and adaptive feedback mechanisms, improving responsiveness and operational efficiency. Hybrid approaches combining offline simulation and real-time control leverage digital twins to create dynamic, continuously updated models that optimize system performance and maintenance strategies.

Conclusion and Final Thoughts

Offline simulation provides a safe and cost-effective environment to test and optimize system models without disrupting actual operations. Real-time control ensures immediate response and adaptation, essential for critical processes requiring dynamic decision-making. Balancing offline simulation and real-time control enhances Your ability to predict issues and maintain system stability efficiently.

Offline Simulation vs Real-time Control Infographic

libmatt.com

libmatt.com