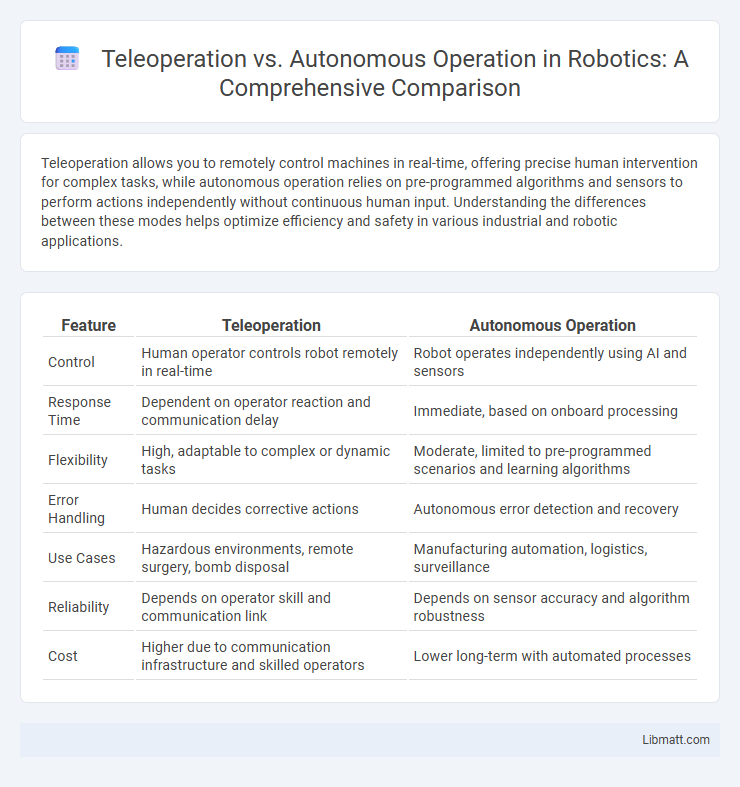

Teleoperation allows you to remotely control machines in real-time, offering precise human intervention for complex tasks, while autonomous operation relies on pre-programmed algorithms and sensors to perform actions independently without continuous human input. Understanding the differences between these modes helps optimize efficiency and safety in various industrial and robotic applications.

Table of Comparison

| Feature | Teleoperation | Autonomous Operation |

|---|---|---|

| Control | Human operator controls robot remotely in real-time | Robot operates independently using AI and sensors |

| Response Time | Dependent on operator reaction and communication delay | Immediate, based on onboard processing |

| Flexibility | High, adaptable to complex or dynamic tasks | Moderate, limited to pre-programmed scenarios and learning algorithms |

| Error Handling | Human decides corrective actions | Autonomous error detection and recovery |

| Use Cases | Hazardous environments, remote surgery, bomb disposal | Manufacturing automation, logistics, surveillance |

| Reliability | Depends on operator skill and communication link | Depends on sensor accuracy and algorithm robustness |

| Cost | Higher due to communication infrastructure and skilled operators | Lower long-term with automated processes |

Introduction to Teleoperation and Autonomous Operation

Teleoperation allows remote control of machines and robots by a human operator, providing real-time input and decision-making from a distance, often used in hazardous or inaccessible environments. Autonomous operation enables machines to perform tasks independently using sensors, artificial intelligence, and pre-programmed algorithms, reducing the need for continuous human intervention. Your choice between teleoperation and autonomous operation depends on factors like task complexity, safety requirements, and the level of control you need.

Key Definitions: Teleoperation vs Autonomous Systems

Teleoperation involves remote control of machinery or vehicles by a human operator, relying on real-time input and feedback for decision-making and maneuvering. Autonomous systems utilize artificial intelligence and sensors to perform tasks without human intervention, enabling self-navigation and real-time adaptive responses. Key differences lie in control source, latency dependency, and the level of human involvement in operational processes.

Core Technologies Enabling Teleoperation

Teleoperation relies on core technologies such as real-time communication networks, high-resolution sensors, and sophisticated control algorithms to enable remote operation of machines with precision. Advanced video streaming, low-latency data transmission, and haptic feedback systems are crucial for replicating human intuition and responsiveness over distance. Integration of AI-based anomaly detection and sensor fusion further enhances situational awareness and operational safety during teleoperated tasks.

Key Technologies Behind Autonomous Operation

Key technologies behind autonomous operation include advanced sensors such as LiDAR, radar, and cameras that enable environment perception and real-time data acquisition. Machine learning algorithms and artificial intelligence process vast amounts of information to make decisions and navigate complex scenarios without human intervention. Your system's efficiency depends heavily on robust software integration and accurate mapping technologies that support continuous learning and adaptation in dynamic environments.

Comparison of Operational Efficiency

Teleoperation enables precise, real-time human control, which can enhance decision-making in complex or unpredictable environments but may introduce latency and require constant connectivity. Autonomous operation relies on pre-programmed algorithms and machine learning to execute tasks independently, often resulting in higher operational efficiency for repetitive or standardized processes due to reduced human intervention. Your choice between teleoperation and autonomy should consider factors like task complexity, required responsiveness, and available infrastructure to maximize efficiency.

Safety and Reliability Concerns

Teleoperation enhances safety by allowing human operators to control machines remotely, reducing exposure to hazardous environments, but it relies heavily on secure communication links to prevent failures and potential cyberattacks. Autonomous operation increases reliability through consistent performance and real-time decision-making using advanced sensors and AI; however, unexpected scenarios or software malfunctions pose significant safety concerns. Evaluating your specific application will help determine whether teleoperation's human oversight or autonomy's precision better mitigates safety and reliability risks.

Human Interaction and Control Levels

Teleoperation relies heavily on continuous human interaction, requiring operators to control machines remotely with precise inputs, ensuring real-time decision-making and adaptability to complex environments. Autonomous operation minimizes direct human control by utilizing advanced algorithms and sensor data to execute tasks independently, which enhances efficiency but demands robust system reliability and programming. The control levels in teleoperation range from full manual input to adjustable assistance, whereas autonomous systems function across varying autonomy degrees, from basic automation to fully independent decision-making.

Application Areas: Teleoperation vs Autonomous Operation

Teleoperation is commonly utilized in hazardous environments such as underwater exploration, space missions, and military operations where direct human presence is risky. Autonomous operation excels in industries like manufacturing, agriculture, and logistics by enabling robots and vehicles to perform tasks independently with real-time decision-making capabilities. Your choice between teleoperation and autonomous systems depends on factors like environmental conditions, task complexity, and required precision.

Challenges and Limitations of Each Approach

Teleoperation faces challenges such as latency, limited bandwidth, and the need for constant human attention, which can impact responsiveness and operational safety. Autonomous operation struggles with limitations in perceiving complex environments, handling unpredictable scenarios, and requiring extensive data for reliable decision-making. Your choice between these methods must weigh the trade-offs between human control precision and the adaptability of autonomous systems.

Future Trends and Industry Outlook

Future trends in teleoperation emphasize enhanced human-machine interfaces and increased reliance on 5G connectivity to enable real-time, low-latency remote control across industries such as mining, agriculture, and logistics. Autonomous operation advancements leverage AI, machine learning, and sensor fusion technologies to improve decision-making accuracy, safety, and scalability in sectors like autonomous vehicles, robotics, and manufacturing. The industry outlook points to hybrid models combining teleoperation and autonomy to maximize operational efficiency, reduce downtime, and address regulatory challenges while accelerating adoption in smart factories and smart cities.

Teleoperation vs Autonomous Operation Infographic

libmatt.com

libmatt.com