A Cartesian robot operates using three linear axes (X, Y, and Z) to achieve precise, rectangular movement ideal for pick-and-place tasks, while a cylindrical robot features a rotary joint combined with linear motion, enabling it to reach areas within a cylindrical work envelope. Understanding the difference helps you select the best robot type for applications requiring either high accuracy in linear paths or versatile access to cylindrical spaces.

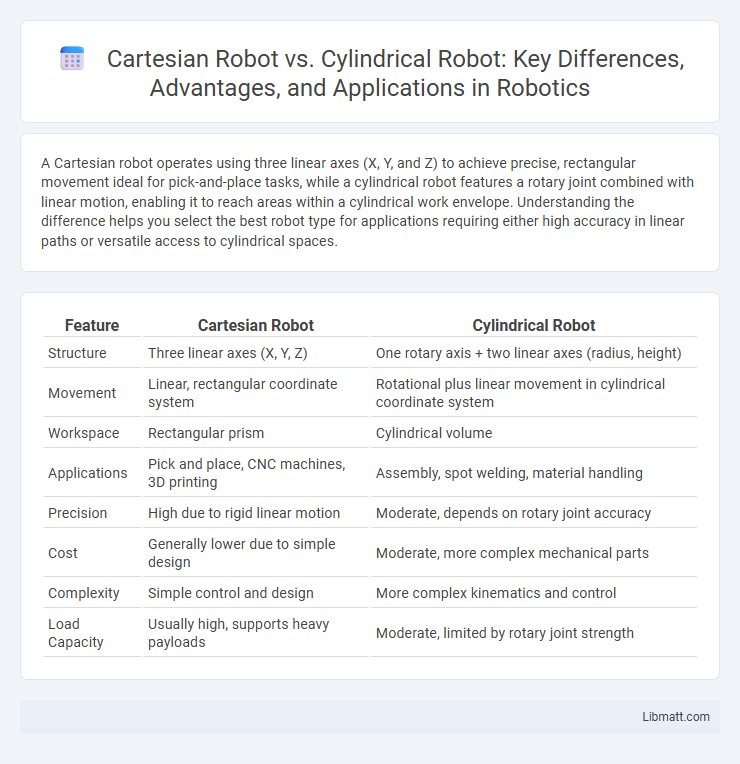

Table of Comparison

| Feature | Cartesian Robot | Cylindrical Robot |

|---|---|---|

| Structure | Three linear axes (X, Y, Z) | One rotary axis + two linear axes (radius, height) |

| Movement | Linear, rectangular coordinate system | Rotational plus linear movement in cylindrical coordinate system |

| Workspace | Rectangular prism | Cylindrical volume |

| Applications | Pick and place, CNC machines, 3D printing | Assembly, spot welding, material handling |

| Precision | High due to rigid linear motion | Moderate, depends on rotary joint accuracy |

| Cost | Generally lower due to simple design | Moderate, more complex mechanical parts |

| Complexity | Simple control and design | More complex kinematics and control |

| Load Capacity | Usually high, supports heavy payloads | Moderate, limited by rotary joint strength |

Introduction to Cartesian and Cylindrical Robots

Cartesian robots utilize three linear axes (X, Y, and Z) arranged orthogonally to provide precise, straight-line movements ideal for pick-and-place, assembly, and CNC machining applications. Cylindrical robots combine rotary motion around a vertical axis with linear movement along one or more axes, allowing for flexible operation in tasks such as welding, material handling, and machine tending. Understanding the fundamental design differences helps you select the best robotic system to optimize accuracy, payload capacity, and workspace for your manufacturing needs.

Basic Structure and Design Differences

Cartesian robots feature a linear structure with three perpendicular axes (X, Y, and Z), allowing straightforward, precise movements ideal for pick-and-place tasks. Cylindrical robots have a rotary joint combined with linear movements, enabling them to operate within a cylindrical work envelope and perform tasks requiring rotational access. The Cartesian design emphasizes simplicity and rigidity, while cylindrical robots offer enhanced flexibility and reach in confined spaces.

Principles of Operation

Cartesian robots operate on three linear axes (X, Y, and Z) using sliding motions along perpendicular rails, enabling precise and straightforward movement within a rectangular workspace. Cylindrical robots combine rotational movement around a fixed vertical axis with linear motion along radial and vertical axes, allowing for circular and vertical positioning within a cylindrical work envelope. Understanding the principles of operation helps you select the right robot based on the required range of motion and workspace geometry.

Key Applications in Industry

Cartesian robots are extensively used in packaging, assembly, and CNC machining due to their precise linear movement across three axes, ideal for operations requiring high accuracy and repeatability. Cylindrical robots excel in welding, material handling, and machine tool operations by offering rotational movement combined with linear motion, allowing efficient access to confined spaces and complex tasks. Both robot types optimize industrial automation by enhancing speed, flexibility, and operational efficiency in manufacturing processes.

Precision and Repeatability Comparison

Cartesian robots offer high precision and repeatability due to their linear motion along the X, Y, and Z axes, making them ideal for tasks requiring consistent accuracy. Cylindrical robots, with their rotary and linear movements, provide moderate precision but often have slightly lower repeatability because of the complexity in joint articulation. Your choice depends on the precision demands of your application, with Cartesian robots typically outperforming cylindrical robots in repeatability metrics.

Work Envelope and Reach Analysis

Cartesian robots feature a rectangular work envelope defined by linear axes along X, Y, and Z directions, offering high precision and repeatability within a well-defined cubic or prismatic space. Cylindrical robots possess a cylindrical work envelope formed by a rotary joint combined with linear movements along the vertical and radial axes, allowing them to reach around objects with rotational flexibility. Your choice depends on whether your application requires straightforward, precise linear motions (Cartesian) or more versatile rotational access within a circular area (Cylindrical).

Programming and Control Systems

Cartesian robots use straightforward linear axes controlled by CNC or PLC systems, making programming simpler with G-code or ladder logic that suits precise, repeatable tasks. Cylindrical robots require more complex programming due to their rotational and linear joint combination, often necessitating specialized robotics languages or advanced motion controllers to handle curved paths and 3D space movement. Your choice between these robots hinges on the complexity of required control algorithms and the ease of integrating them into existing automation systems.

Advantages of Cartesian Robots

Cartesian robots offer superior precision and repeatability due to their linear axis movements along X, Y, and Z coordinates. Their modular design allows for easy customization, scalability, and integration into various automation systems, enhancing production efficiency. You can benefit from their simple control mechanisms and excellent load capacity, making them ideal for applications requiring high accuracy and rigidity.

Benefits of Cylindrical Robots

Cylindrical robots offer enhanced reach and flexibility due to their rotational base combined with vertical and radial movements, making them ideal for applications requiring cylindrical work envelopes such as assembly, welding, and material handling. Their design enables precise positioning within confined spaces, leading to efficient use of workspace and improved productivity in manufacturing environments. Additionally, cylindrical robots typically have simpler mechanical structures, resulting in easier maintenance and lower operational costs compared to Cartesian robots.

Choosing the Right Robot for Your Application

When selecting between a Cartesian robot and a cylindrical robot, consider the workspace configuration and precision requirements; Cartesian robots excel in linear, rectangular workspaces with high accuracy, making them ideal for assembly, pick-and-place, and CNC machining. Cylindrical robots offer rotational movement combined with linear motion, suitable for tasks requiring reach around objects, such as welding or material handling in confined spaces. Evaluating payload capacity, range of motion, and environmental constraints ensures the chosen robot aligns perfectly with your application's operational demands.

Cartesian Robot vs Cylindrical Robot Infographic

libmatt.com

libmatt.com