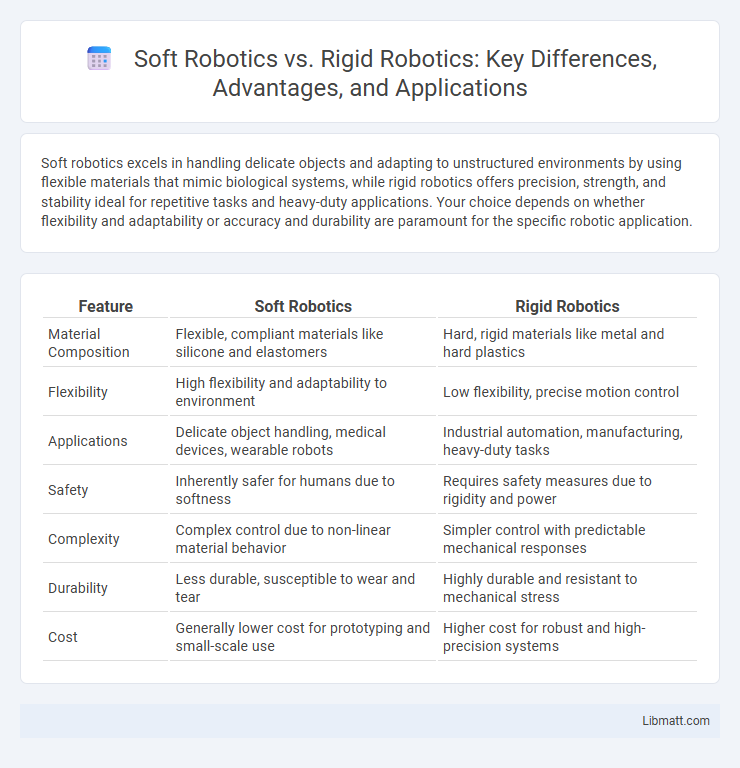

Soft robotics excels in handling delicate objects and adapting to unstructured environments by using flexible materials that mimic biological systems, while rigid robotics offers precision, strength, and stability ideal for repetitive tasks and heavy-duty applications. Your choice depends on whether flexibility and adaptability or accuracy and durability are paramount for the specific robotic application.

Table of Comparison

| Feature | Soft Robotics | Rigid Robotics |

|---|---|---|

| Material Composition | Flexible, compliant materials like silicone and elastomers | Hard, rigid materials like metal and hard plastics |

| Flexibility | High flexibility and adaptability to environment | Low flexibility, precise motion control |

| Applications | Delicate object handling, medical devices, wearable robots | Industrial automation, manufacturing, heavy-duty tasks |

| Safety | Inherently safer for humans due to softness | Requires safety measures due to rigidity and power |

| Complexity | Complex control due to non-linear material behavior | Simpler control with predictable mechanical responses |

| Durability | Less durable, susceptible to wear and tear | Highly durable and resistant to mechanical stress |

| Cost | Generally lower cost for prototyping and small-scale use | Higher cost for robust and high-precision systems |

Introduction to Soft and Rigid Robotics

Soft robotics utilizes flexible, compliant materials like silicone and elastomers to mimic natural movements, enabling delicate interactions and adaptability in unstructured environments. In contrast, rigid robotics relies on hard materials such as metal and plastic, providing high precision, strength, and repeatability for industrial automation tasks. The fundamental distinction lies in the material properties and design principles that influence their applications, with soft robots excelling in gentle manipulation and rigid robots in tasks demanding stiffness and accuracy.

Fundamental Differences Between Soft and Rigid Robots

Soft robotics utilize flexible, compliant materials such as silicone or rubber, allowing for adaptive, gentle interactions with unpredictable environments, while rigid robotics rely on hard, inflexible components like metal or plastic, emphasizing precision and strength. The fundamental differences lie in their structural properties, actuation methods, and control systems, with soft robots often employing fluidic or pneumatic actuators and bio-inspired designs, versus rigid robots using electric motors and gears for movement. Your choice between soft and rigid robotics depends on application requirements, balancing adaptability and safety with accuracy and load capacity.

Materials Used in Soft vs Rigid Robotics

Soft robotics primarily use flexible, compliant materials like silicones, elastomers, and hydrogels that allow for adaptability and safe interaction with humans and delicate objects. Rigid robotics rely on hard materials such as metals, plastics, and carbon fibers, providing strength, precision, and durability for tasks requiring high load capacity and stability. Your choice between soft and rigid robotic systems depends on the application's need for flexibility versus structural rigidity.

Key Applications of Soft Robotics

Soft robotics excels in applications requiring delicate interaction, such as medical devices for minimally invasive surgery and wearable exoskeletons that adapt to human movement. Unlike rigid robotics, soft robots are ideal for handling fragile objects in agriculture and food processing, where flexibility and gentle touch prevent damage. Your choice of soft robotics can enhance tasks involving unpredictable environments or complex, dynamic shapes.

Key Applications of Rigid Robotics

Rigid robotics are extensively utilized in automotive manufacturing for tasks such as welding, assembly, and painting due to their precision and strength. These robots excel in electronics production, enabling high-speed, repetitive processes like PCB assembly and component insertion. In logistics and warehousing, rigid robotic arms enhance material handling efficiency and accuracy, optimizing inventory management and order fulfillment.

Advantages of Soft Robotics

Soft robotics offer enhanced flexibility and adaptability, enabling safer interaction with humans and delicate objects unlike rigid robotics. Their compliance allows for complex, variable shapes and movements, improving performance in unpredictable environments. Soft robots excel in biomedical applications, providing gentle manipulation and reducing the risk of damage to tissues.

Advantages of Rigid Robotics

Rigid robotics offer superior precision and repeatability in tasks such as assembly line manufacturing and welding, making them ideal for high-volume production. Their robust construction allows for handling heavy loads and harsh environments, resulting in greater durability and reliability. Rigid robots also benefit from advanced control systems that enhance speed and accuracy, reducing human error and increasing overall efficiency.

Limitations and Challenges: Soft vs Rigid Robotics

Soft robotics face challenges in precision and load-bearing capacity due to their flexible materials, limiting their use in high-accuracy or heavy-duty tasks compared to rigid robotics. Rigid robotics struggle with adaptability and safety around humans because of their inflexible structures and higher risk of injury during interaction. Both systems require advancements in material science and control algorithms to overcome their respective limitations and enhance performance across diverse applications.

Future Trends in Soft and Rigid Robotics

Future trends in soft robotics emphasize advancements in flexible materials, bio-inspired designs, and enhanced adaptability for complex, unstructured environments, leading to safer human-robot interactions and medical applications. Rigid robotics continue to evolve with increased precision, AI integration, and industrial automation capabilities, driving efficiency in manufacturing and logistics. Your ability to leverage these emerging technologies will determine how effectively you can implement innovative solutions tailored to specific operational needs.

Choosing the Right Robotics: Factors to Consider

When choosing between soft robotics and rigid robotics, consider the specific application requirements such as flexibility, precision, and environmental adaptability. Soft robotics excels in delicate tasks and human interaction due to its compliant materials, while rigid robotics offers higher strength and repeatability for industrial automation. Evaluating your operational environment, payload needs, and maintenance capabilities will help determine the optimal robotic solution for your project.

Soft robotics vs Rigid robotics Infographic

libmatt.com

libmatt.com