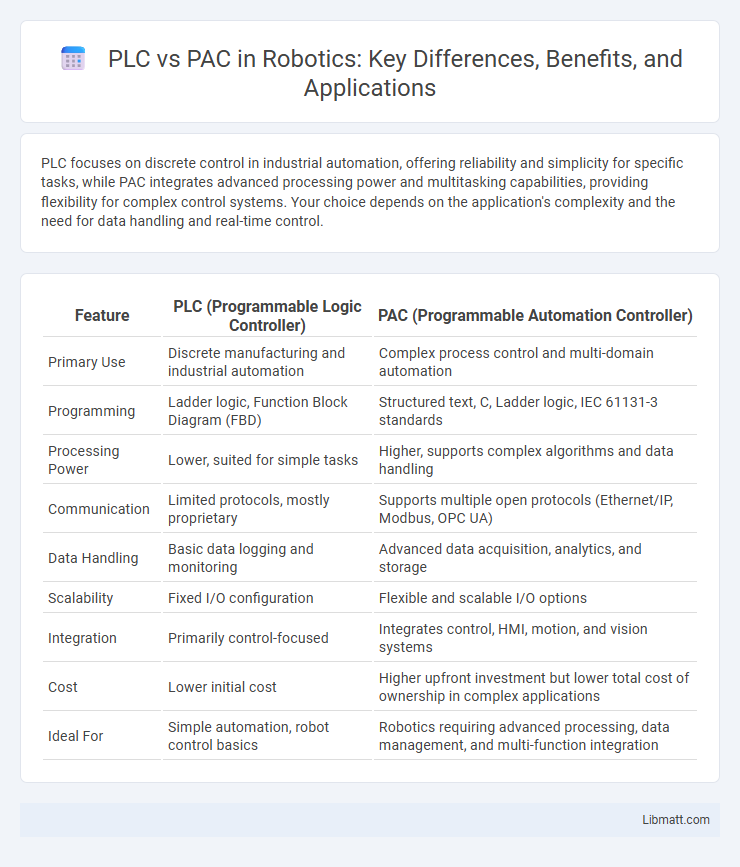

PLC focuses on discrete control in industrial automation, offering reliability and simplicity for specific tasks, while PAC integrates advanced processing power and multitasking capabilities, providing flexibility for complex control systems. Your choice depends on the application's complexity and the need for data handling and real-time control.

Table of Comparison

| Feature | PLC (Programmable Logic Controller) | PAC (Programmable Automation Controller) |

|---|---|---|

| Primary Use | Discrete manufacturing and industrial automation | Complex process control and multi-domain automation |

| Programming | Ladder logic, Function Block Diagram (FBD) | Structured text, C, Ladder logic, IEC 61131-3 standards |

| Processing Power | Lower, suited for simple tasks | Higher, supports complex algorithms and data handling |

| Communication | Limited protocols, mostly proprietary | Supports multiple open protocols (Ethernet/IP, Modbus, OPC UA) |

| Data Handling | Basic data logging and monitoring | Advanced data acquisition, analytics, and storage |

| Scalability | Fixed I/O configuration | Flexible and scalable I/O options |

| Integration | Primarily control-focused | Integrates control, HMI, motion, and vision systems |

| Cost | Lower initial cost | Higher upfront investment but lower total cost of ownership in complex applications |

| Ideal For | Simple automation, robot control basics | Robotics requiring advanced processing, data management, and multi-function integration |

Introduction to PLC and PAC

Programmable Logic Controllers (PLC) are industrial digital computers designed for automation of electromechanical processes, featuring rugged designs suitable for harsh environments and real-time control. Programmable Automation Controllers (PAC) combine the functionality of PLCs with advanced computing capabilities, offering enhanced data handling, integration, and complex control tasks for modern industrial systems. Understanding the differences in architecture and application between PLC and PAC helps you select the right automation solution for your manufacturing or processing needs.

Understanding PLC: Definition and Functions

A Programmable Logic Controller (PLC) is an industrial digital computer designed for automation of electromechanical processes, such as control of machinery on factory assembly lines. It operates in real-time, executing control programs to monitor inputs, make decisions based on programmed logic, and control outputs accordingly. Understanding your PLC's definition and functions is essential for optimizing automation systems and ensuring efficient process control.

What is a PAC? Key Features Explained

A PAC (Programmable Automation Controller) is an advanced industrial control system that combines the functionalities of a PLC (Programmable Logic Controller) with PC-based computing features. Key features of a PAC include enhanced processing power, multi-domain control capabilities (such as motion, logic, and process control), open communication protocols, and scalability for complex automation tasks. Your choice of a PAC enables seamless integration, real-time data analytics, and more flexible programming environments compared to traditional PLCs.

Core Differences Between PLC and PAC

PLCs (Programmable Logic Controllers) excel in discrete control tasks with simple programming architecture, while PACs (Programmable Automation Controllers) offer more advanced capabilities such as complex data handling, multitasking, and integration of multiple automation protocols. PACs combine the reliability of PLCs with the flexibility of PC-based control, supporting higher-level processing and communication functions essential for modern industrial automation. Your choice depends on the complexity of your application and the need for enhanced data management and scalability.

Hardware Architecture Comparison

PLC hardware architecture typically features modular components such as a CPU, power supply, input/output (I/O) modules, and communication interfaces designed for discrete control tasks. PACs incorporate advanced hardware with integrated processing power, multiple communication protocols, and high-density I/O options, enabling complex data handling and control in a unified platform. Your choice depends on the required processing speed, scalability, and flexibility for industrial automation applications.

Programming Capabilities: PLC vs PAC

PACs offer advanced programming capabilities with support for multiple languages including ladder logic, structured text, C, and function block diagrams, enabling complex control and automation tasks. PLCs primarily rely on ladder logic and function block diagrams, making them suitable for straightforward, sequential control processes but less flexible for integration with IT networks or advanced data handling. PACs provide enhanced scalability and data processing power, facilitating real-time analytics and better integration with enterprise systems compared to traditional PLCs.

Scalability and Flexibility in Industrial Automation

PACs offer greater scalability and flexibility in industrial automation compared to traditional PLCs due to their advanced processing power and modular architecture. Unlike PLCs, PACs support complex control strategies, multi-discipline integration, and real-time data handling across multiple systems, enabling seamless expansion and adaptation in dynamic industrial environments. The enhanced communication capabilities and software programmability of PACs facilitate easier customization and upgrades, making them ideal for scalable automation solutions.

Application Areas for PLC and PAC

PLC systems excel in industrial automation, controlling manufacturing processes, assembly lines, and machinery operations due to their robustness and real-time performance. PACs offer broader application areas beyond traditional automation, integrating complex data handling, advanced control algorithms, and network communications in industries like energy management, building automation, and process control. Your choice between PLC and PAC depends on the complexity and scalability requirements of your control system applications.

Cost Implications: Investment and Maintenance

PLC systems generally involve lower initial investment costs and simpler maintenance due to their standard, modular components and widespread availability. PACs, with their advanced processing capabilities and integration flexibility, often require higher upfront expenses and specialized maintenance, impacting your overall budget. Evaluating the total cost of ownership, including scalability and downtime risks, helps determine the most cost-effective choice for your automation needs.

Choosing the Right Controller: PLC or PAC?

Selecting the right controller depends on application complexity and scalability requirements. Programmable Logic Controllers (PLCs) excel in straightforward automation tasks with rapid processing and robust reliability, making them ideal for discrete control systems. Programmable Automation Controllers (PACs) offer advanced data handling, integration, and multi-discipline control capabilities, suited for complex processes requiring higher computational power and flexible communication options.

PLC vs PAC Infographic

libmatt.com

libmatt.com