Pulse width modulation (PWM) offers precise control over power delivery by rapidly switching the signal on and off, which enhances efficiency and reduces heat compared to analog control that varies voltage continuously but can cause energy loss through dissipation. Your choice of PWM or analog control depends on the application's requirements for efficiency, accuracy, and thermal management.

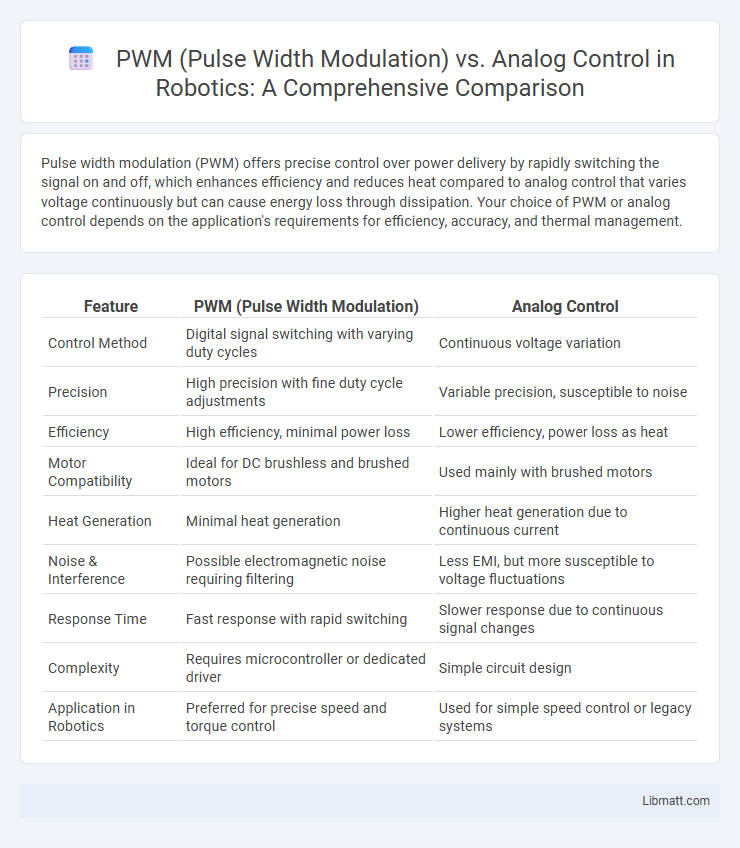

Table of Comparison

| Feature | PWM (Pulse Width Modulation) | Analog Control |

|---|---|---|

| Control Method | Digital signal switching with varying duty cycles | Continuous voltage variation |

| Precision | High precision with fine duty cycle adjustments | Variable precision, susceptible to noise |

| Efficiency | High efficiency, minimal power loss | Lower efficiency, power loss as heat |

| Motor Compatibility | Ideal for DC brushless and brushed motors | Used mainly with brushed motors |

| Heat Generation | Minimal heat generation | Higher heat generation due to continuous current |

| Noise & Interference | Possible electromagnetic noise requiring filtering | Less EMI, but more susceptible to voltage fluctuations |

| Response Time | Fast response with rapid switching | Slower response due to continuous signal changes |

| Complexity | Requires microcontroller or dedicated driver | Simple circuit design |

| Application in Robotics | Preferred for precise speed and torque control | Used for simple speed control or legacy systems |

Introduction to PWM and Analog Control

PWM (Pulse Width Modulation) controls devices by varying the duty cycle of digital pulses to adjust power delivery, offering high efficiency and precise control in applications such as motor speed regulation and LED dimming. Analog control modifies voltage or current continuously, providing simple and smooth control but often with lower energy efficiency and increased heat dissipation. PWM's digital switching approach significantly reduces power loss compared to analog methods, making it ideal for modern energy-saving designs.

Core Principles of PWM

Pulse Width Modulation (PWM) controls device power by switching the signal between on and off states at a high frequency, varying the duty cycle to adjust the effective voltage and current. Unlike analog control, which continuously varies the voltage signal, PWM maintains a constant voltage but changes the pulse duration to regulate the energy delivered. This method enhances efficiency and precision in applications such as motor speed control, LED dimming, and power management.

Fundamentals of Analog Control

Analog control regulates device output by continuously varying voltage or current to achieve the desired performance level, maintaining smooth and precise adjustments without switching states. This method excels in applications requiring fine-tuning and minimal electrical noise, as it directly influences the power delivered through gradual changes. Understanding the fundamentals of analog control enables you to select the optimal approach for systems prioritizing stability and linear response over digital switching benefits.

Key Differences Between PWM and Analog Control

PWM (Pulse Width Modulation) control uses digital signals to regulate power by varying the duty cycle, resulting in higher efficiency and less heat generation compared to analog control, which adjusts voltage continuously. Analog control typically offers smoother transitions but can suffer from power loss and reduced precision in dynamic applications. Your choice between PWM and analog control depends on requirements for efficiency, precision, and heat management in the system.

Efficiency Comparison of PWM vs Analog Control

PWM (Pulse Width Modulation) offers significantly higher efficiency than analog control by minimizing power loss through rapid switching between full-on and full-off states, reducing heat dissipation. Analog control continuously varies voltage, resulting in increased energy loss as heat due to resistive elements. Your systems benefit from PWM's optimized energy use, extending component lifespan and reducing overall power consumption.

Impact on Heat and Power Consumption

PWM (Pulse Width Modulation) controls power delivery by switching the output on and off rapidly, significantly reducing heat generation compared to analog control which adjusts voltage continuously, causing more power dissipation as heat. Your devices benefit from increased energy efficiency with PWM, as it minimizes wasted power and lowers overall consumption, especially in applications like motor speed control or LED dimming. Heat impact is crucial, with PWM favoring cooler operation and prolonging device lifespan, while analog control often results in higher operating temperatures and reduced efficiency.

Applications Best Suited for PWM

PWM (Pulse Width Modulation) is best suited for applications requiring efficient power control and precise speed regulation, such as motor drives, LED dimming, and switching power supplies. It enables energy-efficient operation by rapidly switching power devices on and off, minimizing heat dissipation compared to analog control methods. Industrial automation, robotics, and battery-powered devices commonly use PWM to achieve fine control with reduced power loss and improved system reliability.

Ideal Scenarios for Analog Control

Analog control is ideal in scenarios requiring smooth, continuous signal adjustments without digital switching noise, such as in audio amplifiers or sensitive sensor applications. It provides precise voltage or current regulation for devices needing steady-state operation, including temperature controllers and linear power supplies. Your system benefits from analog control when low electromagnetic interference and simple circuitry are priorities.

Pros and Cons of PWM and Analog Methods

PWM (Pulse Width Modulation) offers high efficiency and precise control of power delivery by rapidly switching the signal on and off, minimizing heat dissipation and energy loss. However, PWM can introduce electrical noise and requires more complex circuitry compared to analog control, which provides smooth and continuous voltage adjustments making it simpler to implement but less efficient and prone to higher power loss through heat. Analog control is favored in applications demanding low noise and linear response, while PWM excels in power-sensitive environments requiring optimized efficiency and thermal management.

Choosing the Right Control Method

Choosing the right control method depends on your application's precision and efficiency requirements; PWM (Pulse Width Modulation) offers superior energy efficiency and fine-tuned control for digital systems by rapidly switching voltage levels. Analog control provides smoother, continuous output signals ideal for simple, low-frequency applications but suffers from higher power loss and less accuracy. When energy conservation and digital integration are priorities, PWM control is often the optimal choice.

PWM (Pulse width modulation) vs Analog control Infographic

libmatt.com

libmatt.com