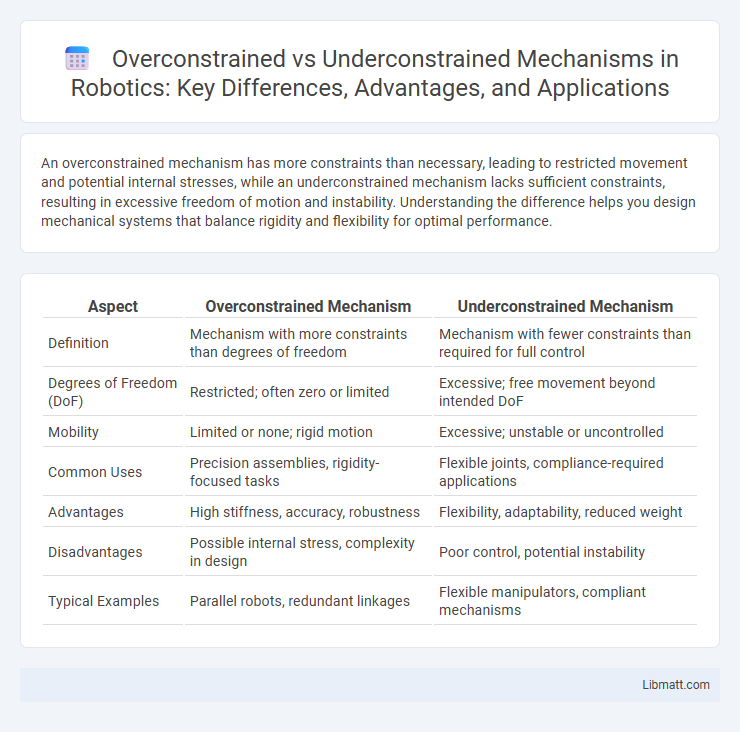

An overconstrained mechanism has more constraints than necessary, leading to restricted movement and potential internal stresses, while an underconstrained mechanism lacks sufficient constraints, resulting in excessive freedom of motion and instability. Understanding the difference helps you design mechanical systems that balance rigidity and flexibility for optimal performance.

Table of Comparison

| Aspect | Overconstrained Mechanism | Underconstrained Mechanism |

|---|---|---|

| Definition | Mechanism with more constraints than degrees of freedom | Mechanism with fewer constraints than required for full control |

| Degrees of Freedom (DoF) | Restricted; often zero or limited | Excessive; free movement beyond intended DoF |

| Mobility | Limited or none; rigid motion | Excessive; unstable or uncontrolled |

| Common Uses | Precision assemblies, rigidity-focused tasks | Flexible joints, compliance-required applications |

| Advantages | High stiffness, accuracy, robustness | Flexibility, adaptability, reduced weight |

| Disadvantages | Possible internal stress, complexity in design | Poor control, potential instability |

| Typical Examples | Parallel robots, redundant linkages | Flexible manipulators, compliant mechanisms |

Introduction to Constrained Mechanisms

Constrained mechanisms are designed to restrict the motion of mechanical components to achieve specific movements or tasks. Overconstrained mechanisms have more constraints than degrees of freedom, often leading to increased rigidity but potential binding or stress, while underconstrained mechanisms have fewer constraints, resulting in unwanted or excessive motion. Understanding the balance between constraints and degrees of freedom is crucial for optimizing your mechanism's performance and reliability.

Defining Overconstrained Mechanisms

Overconstrained mechanisms are mechanical systems that have more constraints than necessary for motion control, causing internal stresses and potential binding. These mechanisms often maintain structural rigidity even if some components fail, but require precise design to avoid interference and wear. Understanding overconstrained mechanisms helps you optimize performance in robotics, machinery, and complex linkages by balancing constraint and flexibility.

Understanding Underconstrained Mechanisms

Underconstrained mechanisms have fewer constraints than degrees of freedom, allowing parts to move freely within certain limits and resulting in flexible, adaptable motion paths. Understanding these mechanisms is crucial for designing compliant systems that can accommodate misalignments or variations without binding or jamming. You can optimize functionality in robotics and mechanical assemblies by leveraging underconstrained designs to enable controlled flexibility while maintaining structural integrity.

Fundamental Differences Between Overconstrained and Underconstrained Mechanisms

Overconstrained mechanisms have more constraints than degrees of freedom, resulting in limited or no motion due to excess restrictions, while underconstrained mechanisms possess fewer constraints than needed, allowing unintended or excessive movement. The fundamental difference lies in the balance between constraints and degrees of freedom: overconstrained systems risk binding and stress due to redundancy, whereas underconstrained systems face instability and lack of control. Accurate design requires matching constraints to mobility requirements to ensure proper function without interference or looseness.

Kinematic Analysis of Mechanisms

Overconstrained mechanisms exhibit excessive constraints, resulting in redundant constraints that affect their mobility and require specialized kinematic analysis methods to accurately predict motion and avoid system binding. Underconstrained mechanisms have fewer constraints than degrees of freedom, allowing unintended movement and requiring kinematic analysis to identify and control extra degrees of freedom for stable operation. Precise kinematic analysis of both overconstrained and underconstrained mechanisms is essential for optimizing mechanism design, ensuring desired motion accuracy, and enhancing system reliability.

Common Applications of Overconstrained Mechanisms

Overconstrained mechanisms are widely used in precision engineering applications such as robotic arms, aerospace linkages, and compliant mechanisms where increased stiffness and accuracy are critical. These systems exploit redundant constraints to enhance load-bearing capacity and reduce unwanted degrees of freedom, improving overall stability and performance. You will often find overconstrained mechanisms in high-precision manufacturing equipment and advanced structural assemblies where reliability under complex loading conditions is essential.

Typical Uses of Underconstrained Mechanisms

Underconstrained mechanisms are widely used in compliant mechanisms and precision engineering where flexibility and adaptability are essential. They are favored in applications like robotic joints, flexible hinges, and compliant sensors because they allow controlled motion with fewer rigid constraints, improving sensitivity and durability. Your designs benefit from underconstrained mechanisms by enabling smooth, predictable movement while reducing stress concentrations and the need for complex assembly.

Advantages and Disadvantages of Each Mechanism Type

Overconstrained mechanisms offer increased rigidity and precision by restricting motion beyond the minimum requirements, leading to enhanced stability and accuracy in applications like robotics and manufacturing, but they can cause high internal stresses and potential binding issues. Underconstrained mechanisms provide greater flexibility and tolerance for misalignment, allowing smoother movement and easier assembly, yet they may suffer from reduced positional accuracy and stability under load. Your choice depends on whether precision or flexibility is paramount for the specific mechanical system design.

Design Considerations for Selecting Mechanism Constraints

Design considerations for selecting mechanism constraints focus on balancing rigidity and flexibility to ensure optimal performance; overconstrained mechanisms provide higher stiffness and precision but risk binding and increased wear, while underconstrained mechanisms offer adaptability and reduced stress but may suffer from instability and poor repeatability. Engineers evaluate load conditions, desired degrees of freedom, manufacturing tolerances, and application-specific requirements to determine the appropriate constraint level. Your choice impacts the mechanism's durability, accuracy, and maintenance needs, making careful trade-off analysis essential during the design phase.

Future Trends in Mechanism Design and Innovation

Future trends in mechanism design increasingly emphasize the integration of adaptive control systems to optimize overconstrained mechanisms, enhancing precision and durability in robotic applications. Underconstrained mechanisms benefit from advancements in compliant materials and biomimetic design, enabling more flexible and efficient movements in soft robotics. Innovations in simulation and AI-driven optimization methods further accelerate the development of hybrid mechanisms that dynamically balance constraint levels for improved performance and resilience.

Overconstrained Mechanism vs Underconstrained Mechanism Infographic

libmatt.com

libmatt.com