Choosing between 24V DC and 48V DC for robotics depends on the power requirements and efficiency of your system, with 48V DC offering higher power transmission efficiency and reduced current draw, which minimizes heat loss and wire gauge size. Your robotics application may benefit from 48V DC in high-torque motors and longer cable runs, while 24V DC is often sufficient for lower power, compact designs.

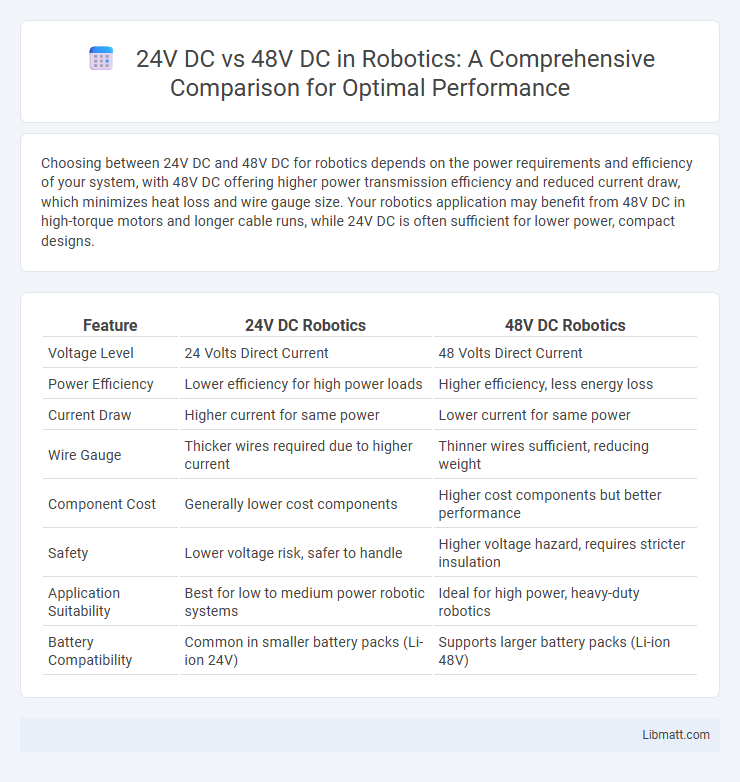

Table of Comparison

| Feature | 24V DC Robotics | 48V DC Robotics |

|---|---|---|

| Voltage Level | 24 Volts Direct Current | 48 Volts Direct Current |

| Power Efficiency | Lower efficiency for high power loads | Higher efficiency, less energy loss |

| Current Draw | Higher current for same power | Lower current for same power |

| Wire Gauge | Thicker wires required due to higher current | Thinner wires sufficient, reducing weight |

| Component Cost | Generally lower cost components | Higher cost components but better performance |

| Safety | Lower voltage risk, safer to handle | Higher voltage hazard, requires stricter insulation |

| Application Suitability | Best for low to medium power robotic systems | Ideal for high power, heavy-duty robotics |

| Battery Compatibility | Common in smaller battery packs (Li-ion 24V) | Supports larger battery packs (Li-ion 48V) |

Introduction to 24V DC and 48V DC in Robotics

24V DC and 48V DC power systems are fundamental in robotics, influencing performance, efficiency, and design complexity. 24V DC is commonly used for low to medium power applications, offering safety advantages and compatibility with a wide range of sensors and actuators. Your choice between 24V DC and 48V DC will impact torque output, current draw, and energy efficiency, making it crucial to match voltage requirements with your robot's operational demands.

Voltage Fundamentals: Understanding 24V DC vs 48V DC

24V DC and 48V DC are common voltage levels used in robotics, each offering distinct advantages in power delivery and efficiency. A 48V DC system can provide higher power with lower current, reducing losses and allowing for thinner wiring compared to 24V DC systems. Understanding the voltage fundamentals between 24V DC and 48V DC helps optimize motor control, battery life, and overall system performance in robotic applications.

Power Efficiency Comparison

48V DC systems in robotics generally offer higher power efficiency compared to 24V DC setups due to lower current flow for the same power output, reducing resistive losses and heat generation in cables and components. Robotics employing 48V DC benefit from improved energy transmission efficiency, enabling more compact wiring and enhanced overall system reliability. This efficiency gain is critical in applications requiring long cable runs or high torque motors, where minimizing voltage drop and energy loss directly impacts performance and operational cost.

Cost Implications: Upfront & Long-Term

24V DC robotics systems generally incur lower upfront costs due to cheaper components and simpler wiring compared to 48V DC systems. However, 48V DC setups offer better energy efficiency and reduced current losses, leading to lower long-term operational and maintenance expenses. Choosing between 24V and 48V DC impacts total cost of ownership, with 48V providing potential savings in energy costs and system durability over time.

Safety Considerations for Robots

Choosing between 24V DC and 48V DC robotics systems significantly impacts safety considerations in industrial environments. A 24V DC system is generally safer due to its lower voltage, reducing the risk of electric shock and complying with extra-low voltage (ELV) safety standards, making it ideal for close human-robot interaction. Your selection should evaluate the trade-off between power efficiency of 48V DC systems and the increased safety profile that 24V DC systems offer in collaborative robotic applications.

Component Availability and Compatibility

Choosing between 24V DC and 48V DC in robotics significantly impacts component availability and compatibility. Most industrial-grade sensors, actuators, and controllers are widely standardized for 24V systems, ensuring easier sourcing and integration. However, 48V DC components, while less common, often offer improved efficiency and higher power capacity, but may require specialized parts that could limit compatibility with your existing setup.

Performance and Speed Impacts

48V DC robotics systems deliver higher torque and faster acceleration compared to 24V DC systems due to improved power efficiency and reduced current loss. The increased voltage enables motors to operate at higher speeds and handle heavier loads without overheating, enhancing overall robot performance. Consequently, 48V configurations support more demanding robotic applications requiring rapid response and sustained power.

Applications Best Suited for 24V DC

24V DC systems are commonly used in robotics applications requiring moderate power levels, such as small to medium-sized robots for precise control and efficient energy use. They are best suited for mobile robots, automated guided vehicles (AGVs), and desktop robotic arms where lower voltage enhances safety and simplifies power management. The 24V DC standard supports compact system design with readily available components and accessories, benefiting cost-sensitive and space-constrained projects.

Use Cases Favoring 48V DC Systems

48V DC systems are favored in robotics requiring high power density and extended operational range, such as autonomous mobile robots (AMRs) and industrial automation platforms where efficiency and reduced current losses are critical. These systems enable smaller gauge wiring and lighter battery packs, enhancing mobility and payload capacity in robotic arms and electric vehicles. Higher voltage also supports advanced motor control and faster acceleration, crucial for logistics robots in warehouse environments.

Choosing the Right Voltage for Your Robotics Project

Selecting the appropriate voltage for robotics projects hinges on power efficiency, component compatibility, and application requirements. A 24V DC system offers easier integration with common actuators and sensors, ideal for smaller robots with moderate power demands. In contrast, 48V DC systems deliver higher power efficiency and reduced current, benefiting larger robots or those needing extended battery life and stronger motors.

24V DC vs 48V DC Robotics Infographic

libmatt.com

libmatt.com