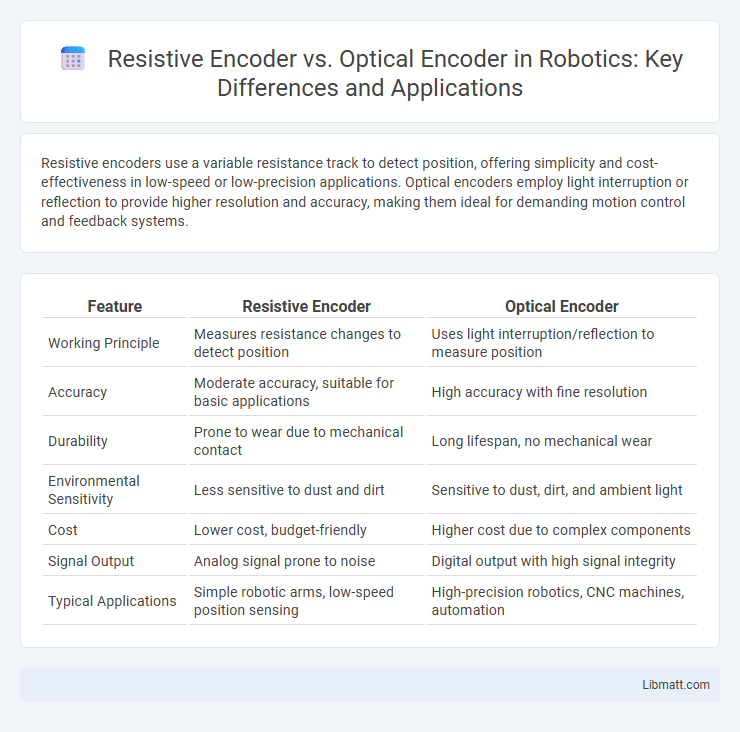

Resistive encoders use a variable resistance track to detect position, offering simplicity and cost-effectiveness in low-speed or low-precision applications. Optical encoders employ light interruption or reflection to provide higher resolution and accuracy, making them ideal for demanding motion control and feedback systems.

Table of Comparison

| Feature | Resistive Encoder | Optical Encoder |

|---|---|---|

| Working Principle | Measures resistance changes to detect position | Uses light interruption/reflection to measure position |

| Accuracy | Moderate accuracy, suitable for basic applications | High accuracy with fine resolution |

| Durability | Prone to wear due to mechanical contact | Long lifespan, no mechanical wear |

| Environmental Sensitivity | Less sensitive to dust and dirt | Sensitive to dust, dirt, and ambient light |

| Cost | Lower cost, budget-friendly | Higher cost due to complex components |

| Signal Output | Analog signal prone to noise | Digital output with high signal integrity |

| Typical Applications | Simple robotic arms, low-speed position sensing | High-precision robotics, CNC machines, automation |

Introduction to Encoder Technologies

Resistive encoders utilize variable resistance to detect position changes by measuring voltage variations, making them suitable for low-cost and simple applications. Optical encoders rely on light interruption through patterned discs and photodetectors, providing high-resolution and precise feedback for complex motion control systems. Both encoder technologies serve essential roles in automation, robotics, and industrial machinery by converting mechanical position into electronic signals.

What Is a Resistive Encoder?

A resistive encoder measures position by detecting changes in electrical resistance along a resistive track or element. These encoders generate an analog signal proportional to the angular or linear position of a rotating or sliding component. Commonly used in applications requiring simple, cost-effective position feedback, resistive encoders offer robust performance in harsh environments but generally provide lower resolution compared to optical encoders.

What Is an Optical Encoder?

An optical encoder is a precision sensor that converts mechanical motion into electronic signals using a light source, a photodetector, and a coded disc or strip. It offers high resolution and accuracy by detecting interruptions or reflections of light patterns as the shaft or object moves. Your choice of an optical encoder enhances position feedback systems in robotics, industrial automation, and motion control applications.

Core Operating Principles: Resistive vs Optical

Resistive encoders operate by converting position into a variable resistance using a wiper moving along a resistive track, where changes in resistance correspond directly to angular or linear displacement. Optical encoders rely on light interruption or reflection, employing a coded disk and photodetectors to convert mechanical motion into digital signals with high precision and resolution. The fundamental difference lies in resistive encoders measuring analog resistance changes, while optical encoders detect digital optical patterns for position feedback.

Accuracy and Resolution Differences

Resistive encoders generally offer lower accuracy and resolution compared to optical encoders due to their reliance on variable resistance changes, which can be influenced by noise and wear. Optical encoders use light interruption or reflection methods, providing higher precision with resolutions often exceeding thousands of pulses per revolution, ideal for applications requiring fine positional feedback. When choosing between the two, consider that your application's performance depends heavily on the accuracy and resolution specifications that optical encoders typically surpass.

Durability and Environmental Suitability

Resistive encoders offer superior durability in harsh environments due to their robust construction and resistance to dust, dirt, and moisture, making them ideal for heavy industrial applications. Optical encoders provide high precision but are more vulnerable to contamination and mechanical wear, which can affect performance in dusty or wet conditions. Environmental suitability favors resistive encoders for rugged use, while optical encoders excel in clean, controlled settings requiring fine resolution.

Cost Comparison: Resistive vs Optical Encoders

Resistive encoders generally offer a lower initial cost compared to optical encoders due to simpler construction and materials, making them ideal for budget-sensitive applications. Optical encoders, though more expensive, provide higher resolution and greater accuracy, which can reduce long-term operational costs by minimizing errors in critical control systems. When comparing total cost of ownership, resistive encoders may require more frequent replacement and maintenance, potentially increasing lifetime expenses relative to the more durable optical encoders.

Common Applications for Each Encoder Type

Resistive encoders are widely used in low-cost applications such as joysticks, volume controls, and position sensors in industrial machinery due to their simplicity and durability in harsh environments. Optical encoders find common applications in precision devices like robotic arms, CNC machines, and medical equipment where high resolution and accuracy are critical. Both encoder types serve essential roles in motion control systems, but resistive encoders excel in cost-sensitive and rugged tasks, while optical encoders dominate scenarios demanding exact position feedback.

Pros and Cons: Resistive Encoders vs Optical Encoders

Resistive encoders offer simplicity, cost-effectiveness, and robustness against dust and moisture but suffer from lower resolution and susceptibility to wear due to mechanical contact. Optical encoders provide higher precision and reliability in detecting position with minimal mechanical degradation, yet they are more expensive and vulnerable to contamination like dust and oil, which can impair performance. Choosing between resistive and optical encoders depends on the specific application requirements for accuracy, environmental conditions, and budget constraints.

Choosing the Right Encoder for Your Needs

Selecting the right encoder depends on application requirements, with resistive encoders excelling in cost-sensitive, low-precision scenarios due to their simple construction and durability. Optical encoders deliver high resolution and accuracy, making them ideal for robotics, CNC machines, and precise motion control systems. Evaluating factors such as environmental conditions, desired precision, and budget ensures optimal performance and longevity in the chosen encoder type.

Resistive Encoder vs Optical Encoder Infographic

libmatt.com

libmatt.com